Cutting equipment for disassembling train container

A kind of cutting equipment and flame cutting technology, which is applied in the direction of gas flame welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of unable to cut off the side wall of the rib column and the corresponding position, and achieve the effect of reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

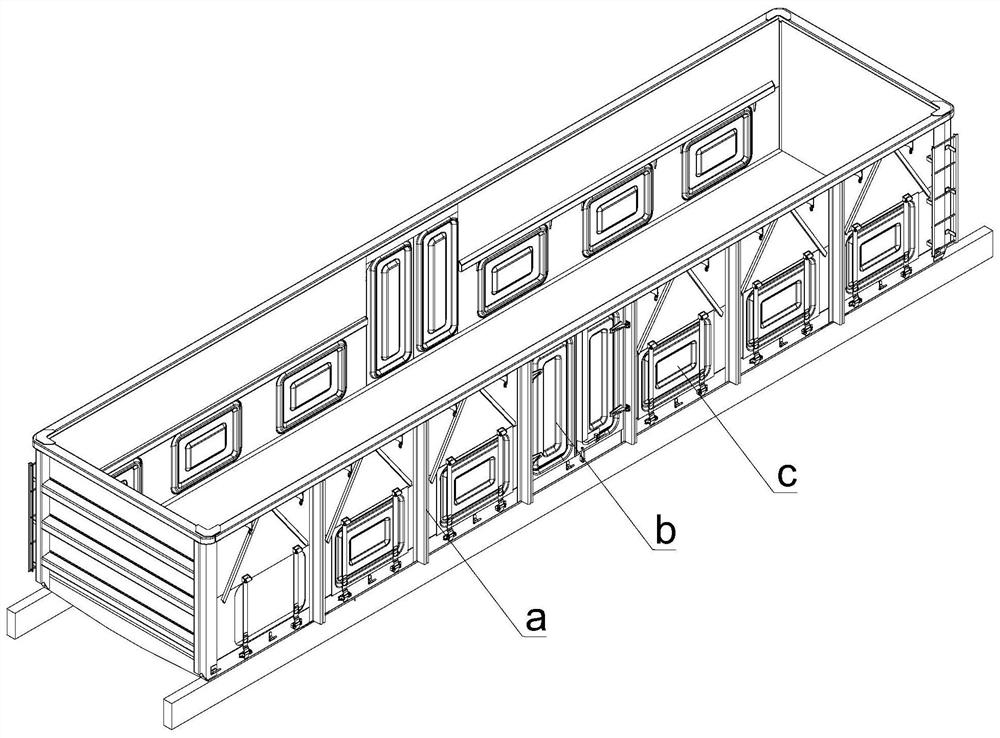

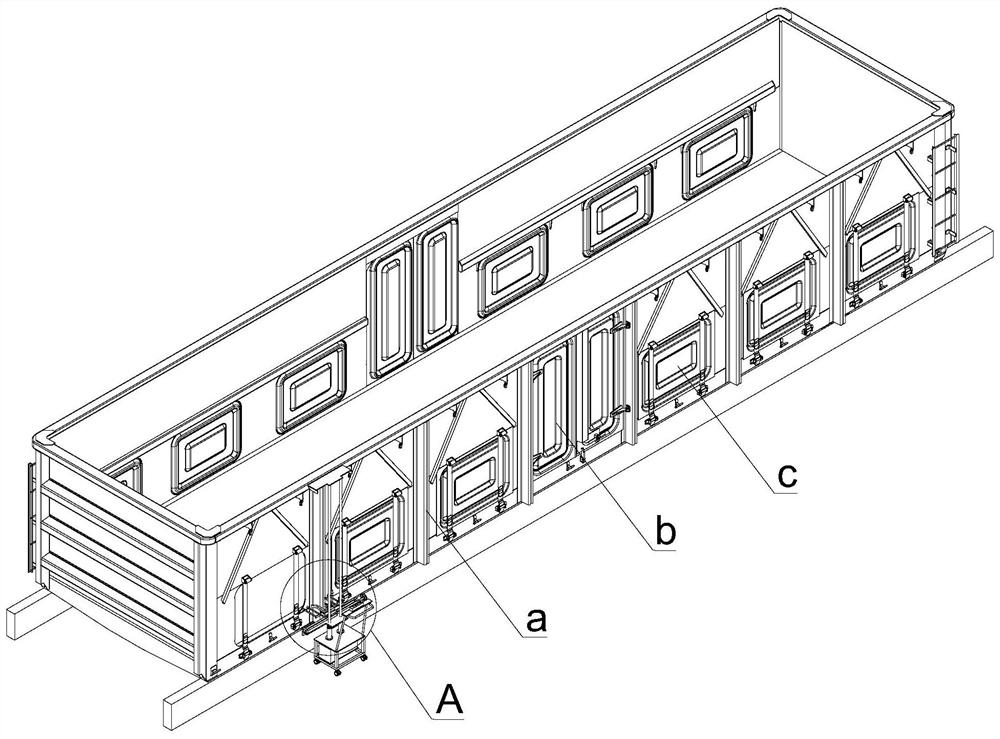

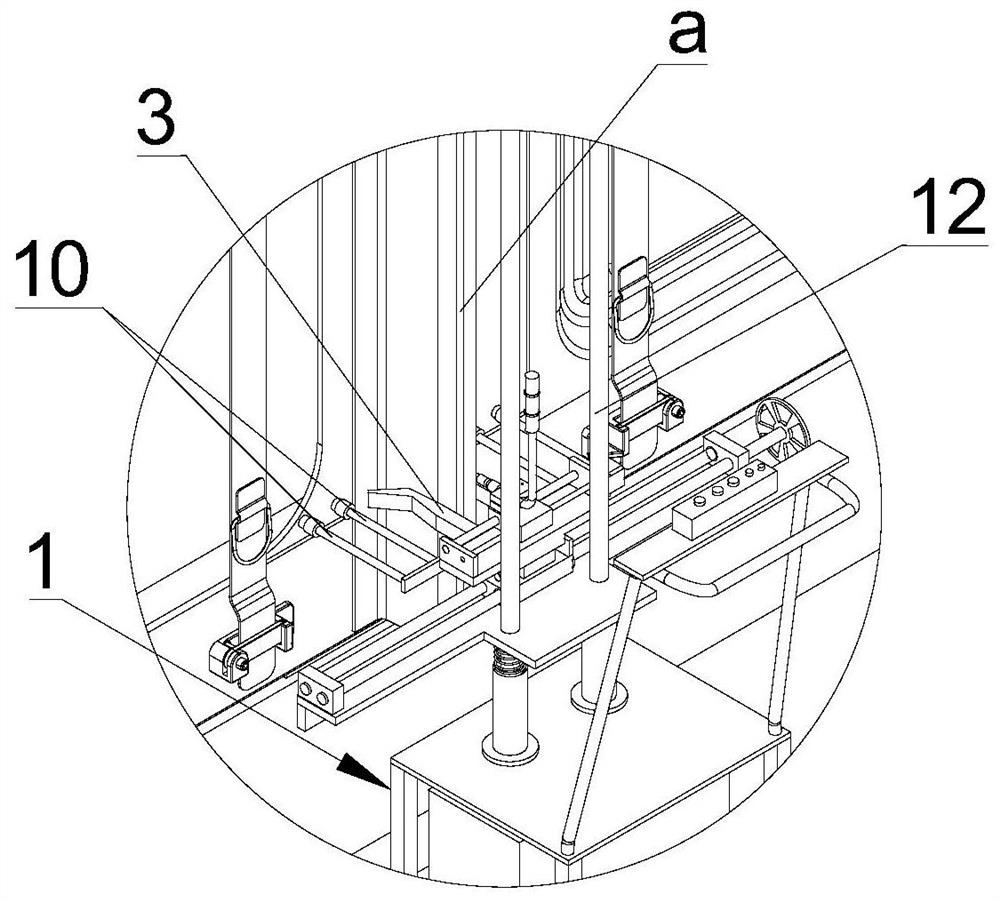

[0040] see Figure 2-6, the cutting equipment for the disintegration of the train container in this embodiment includes a movable cutting trolley 1 and a positioning mechanism and a cutting mechanism arranged on the cutting trolley 1, and the cutting trolley 1 is provided with a handle 1-1. The cutting mechanism is arranged on the positioning mechanism, and the cutting mechanism includes a flame cutting gun 2 and a cutting drive mechanism for driving the flame cutting gun 2 to cut and move; the driving direction of the cutting drive mechanism is parallel to the length direction of the container; The positioning mechanism includes an X-direction positioning mechanism for realizing the positioning of the flame cutting torch 2 in the length direction of the container, a Y-direction positioning mechanism for realizing the positioning of the flame cutting torch 2 in the width direction of the container, and In order to realize the Z-direction positioning mechanism for the positioni...

Embodiment 2

[0056] Different from Embodiment 1, the X-direction positioning mechanism is arranged on the Y-direction positioning mechanism, and the Y-direction positioning mechanism is arranged on the Z-direction positioning mechanism. Of course, other layout methods can also be used to achieve positioning in three directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com