Multi-axially enhanced bi-stretch composite warp-knitted fabric for western-style clothes

A multi-axial, four-way elastic technology, applied in the field of textile fabrics, can solve problems such as single function, achieve comfortable wearing, improve comfort, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

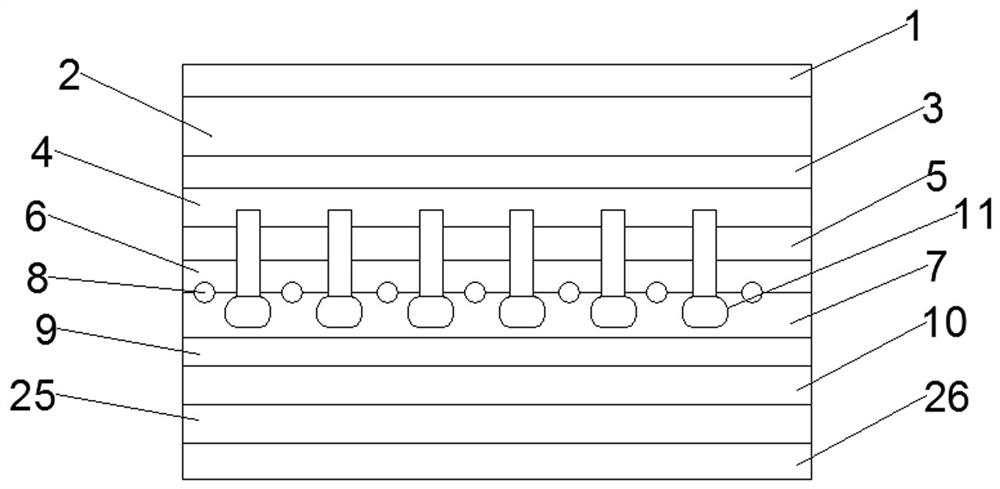

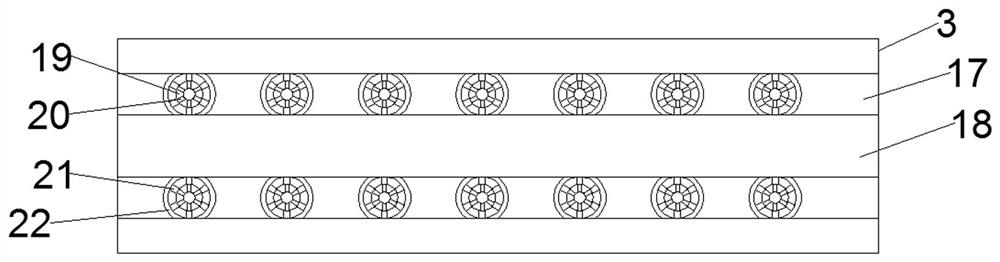

[0027] Embodiment one, such as figure 1 - As shown in - 5, a multi-axially reinforced four-way elastic composite warp-knitted fabric for suits according to an embodiment of the present invention includes a polyester fiber layer 2, and viscose yarn 1 is arranged on the top of the polyester fiber layer 2, so that The bottom of the polyester fiber layer 2 is provided with a hydrophobic layer 3, and the inner bottom of the hydrophobic layer 3 is provided with two diverter blocks 17, and a drainage channel 18 is formed between the two diverter blocks 17, and the top of the diverter block 17 Several deflector blocks 19 are provided, and several deflector grooves 20 are provided on the side of the deflector block 19. The top of the deflector block 19 and the outside of the deflector block 19 are provided with several connecting Groove 21, the diversion groove 20 is connected to the connection groove 21, the top of the diverter block 17 and the outside of the connection groove 21 is p...

Embodiment 2

[0028] Embodiment 2, the mixed textile containing photocatalyst fibers in the polyester fiber layer 2 contains a large amount of photocatalyst fibers, the first waterproof layer 4 is made of polypropylene fiber material, and the second waterproof layer 6 is made of acrylic fiber material As a result, the hydrophobic layer 3 is partially water-repellent yarn formed by interweaving raw cotton yarns and hydrophilic sand threads, and the raw cotton yarns account for at least 55% of the surface of the hydrophobic layer 3 . It is not difficult to see from the above design that through the arrangement of the photocatalyst fiber, the photocatalyst fiber can produce a strong catalytic degradation function under the action of ultraviolet light and visible light, which can effectively kill a variety of bacteria, and also has functions such as deodorization and anti-pollution, which greatly improves people's health. The antibacterial ability in the wild can also play a deodorizing role, fr...

Embodiment 3

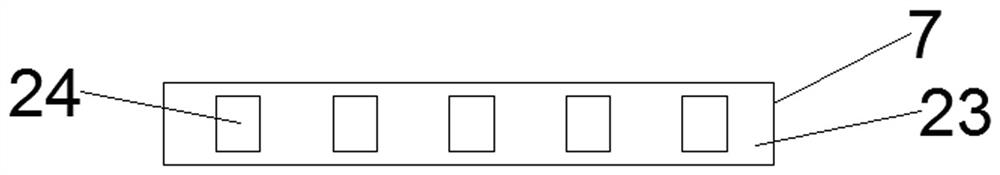

[0029] Embodiment 3, the sweat-absorbing layer 7 includes cotton fibers 23 and pineapple fibers 24, the cotton fibers 23 are provided with several pineapple fibers 24, the surface of the cotton fibers 23 has a twill structure, and the cotton fibers 23 have a twill structure. The lower surface of the fiber 23 is provided with a brushed structure, the cross-section of the pineapple fiber 24 is circular, and the distance between two adjacent pineapple fibers 24 is equal. It is not difficult to find out from above-mentioned design, through the setting of cotton fiber 23 and pineapple fiber 24, improve the touch softness of fabric, make the wearing of fabric more comfortable, make fabric absorb sweat and ventilate, crisp and wrinkle-free, comfortable to wear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com