Blade hoisting tool and hydraulic system thereof

A hydraulic system and hoisting technology, applied in the safety of fluid pressure actuation system, fluid pressure actuation system components, transportation and packaging, etc., can solve the problems of low operation efficiency, poor safety, affecting the normal operation of the unit, etc., and improve the installation Efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

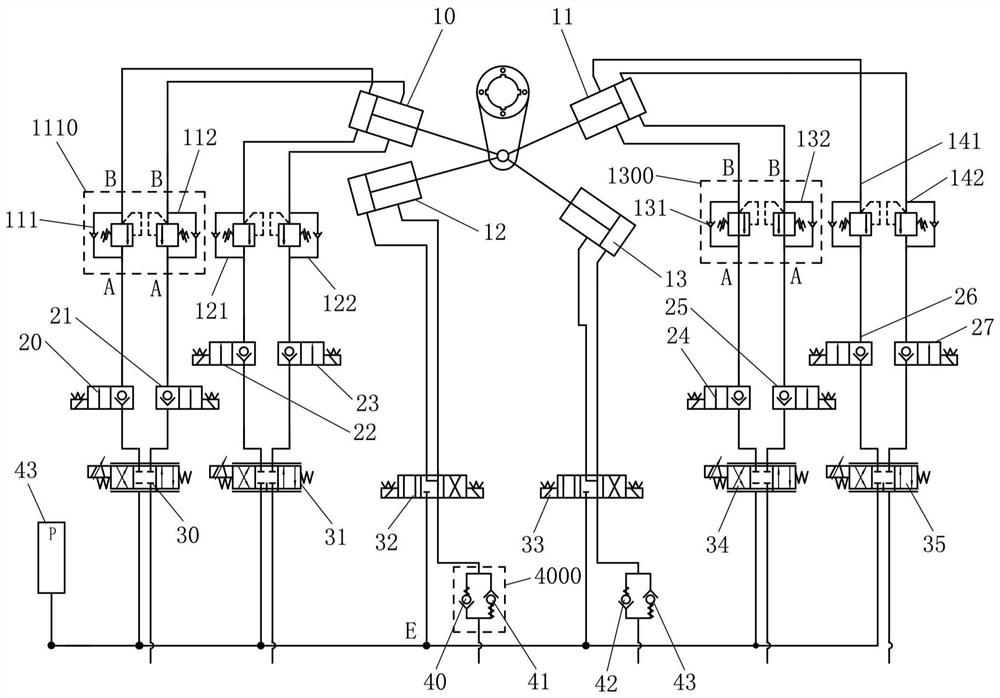

[0030] The hydraulic system according to the embodiment of the present application can drive at least two oil cylinders to expand and contract asynchronously, and can be adapted to drive the pitching and rotating mechanism of the blade hoisting tool, so as to adjust the attitude of the blade during hoisting, such as the tilt angle or pitch angle.

[0031] Embodiments of the present application will be described below with reference to the drawings in which like reference numerals designate like parts throughout.

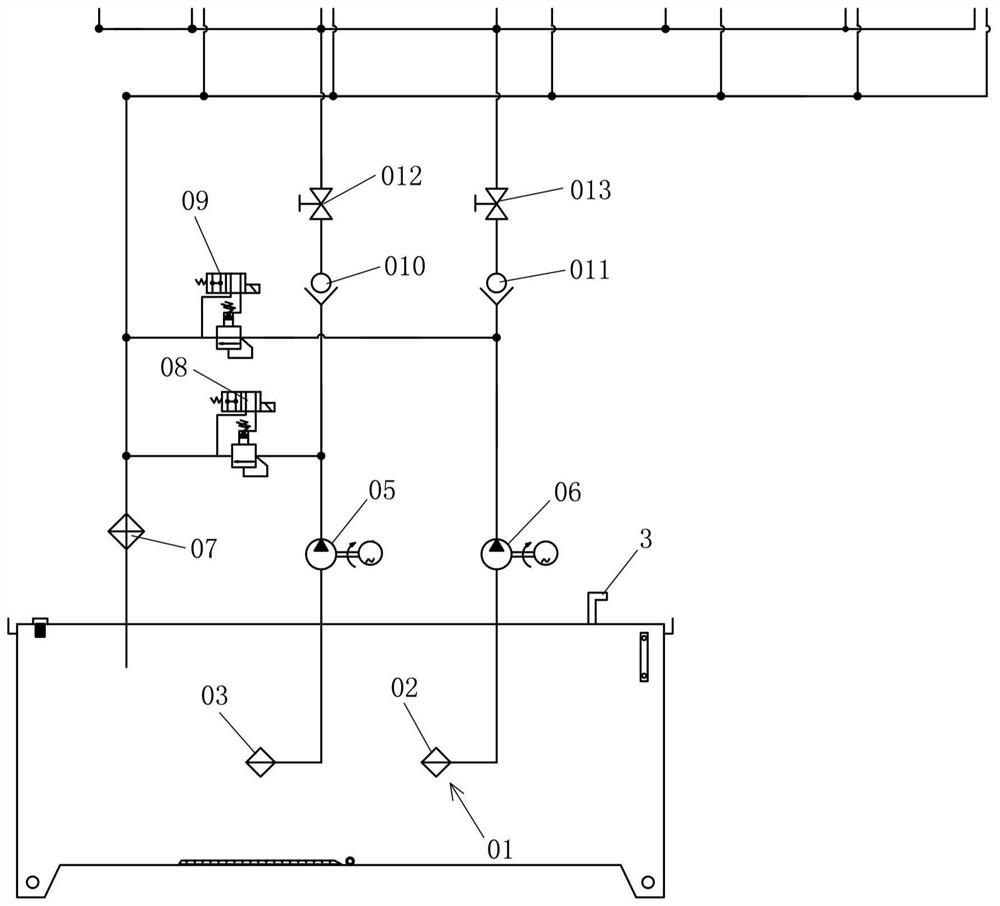

[0032] Figure 1 to Figure 3 is a schematic diagram of a hydraulic system according to an embodiment of the present application.

[0033] A hydraulic system according to an embodiment of the present application may include driving units 05 and 06 , a first pressure maintaining unit 1110 , a second pressure maintaining unit 1300 , a first valve unit 30 and a second valve unit 34 .

[0034] The drive units 05 and 06 can be the power elements of the hydraulic system, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com