Follow-up support system for building jacking construction

A technology for supporting systems and buildings, applied in construction, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult installation, high risk, poor flatness of the superstructure, etc., and achieve easy installation and use, high safety and reliability. , the effect of good safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

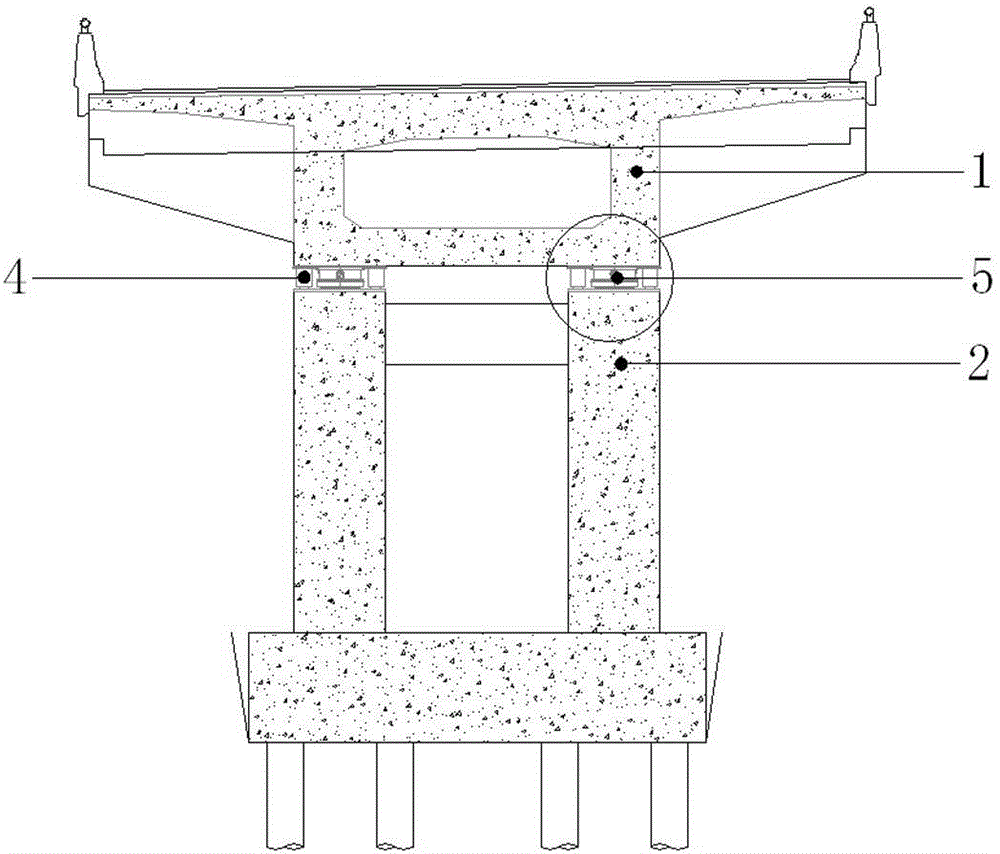

[0033] see Figure 1-3 As shown, the superstructure of the bridge involved in this embodiment adopts a three-span variable cross-section prestressed concrete continuous box girder 1 , and the bottom of the continuous box girder 1 is supported by pier 2 . see figure 1 , The pier 2 in this embodiment includes two main piers and two side piers. Based on this structure, this embodiment adopts the direct jacking method, that is, the pier 2 (main pier and side pier) is used as the counter force basis, and the jacking hydraulic cylinder 4 is installed between the pier 2 and the bottom of the continuous box girder 1, through the PLC computer Synchronous control, the method of jacking up the box girder as a whole (the upper part of the box girder needs to be reinforced) achieves the purpose of raising the deck level of the main bridge.

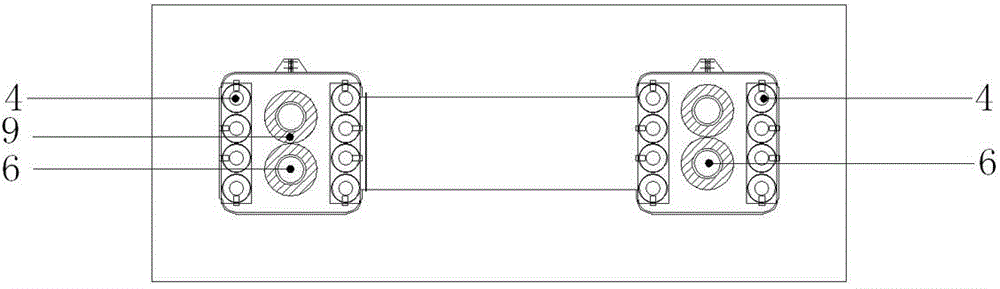

[0034] The follow-up support system mainly includes a follow-up housing 9 and a follow-up hydraulic cylinder 5 . in:

[0035] The following housin...

Embodiment 2

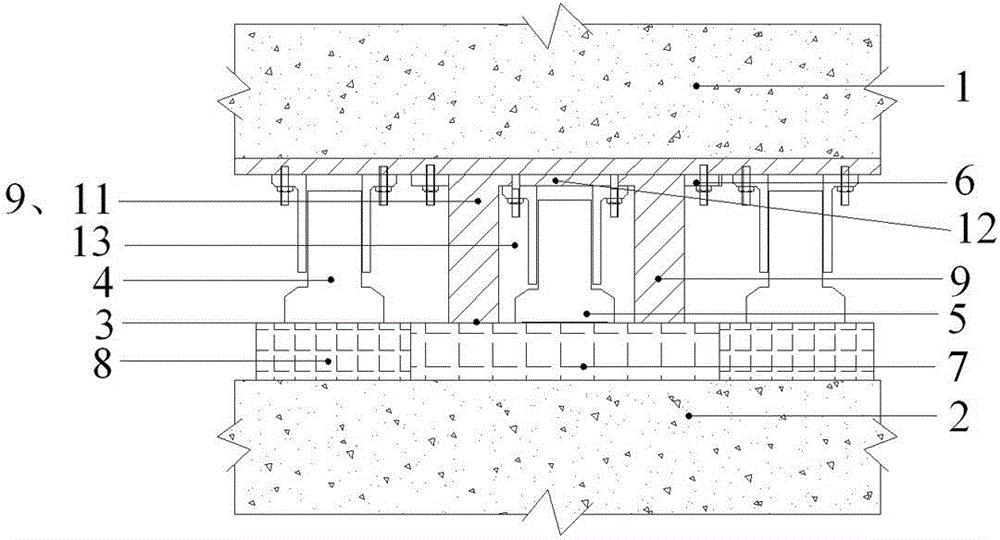

[0048] see Figure 4-5 In this embodiment 2, a number of reinforcing ribs 10 are arranged in the following housing 9, and the reinforcing ribs 10 are vertically welded on the installation bottom plate 12, and the end faces on both sides are welded to the inner surface of the side plate 11 or welded to each other, and The following housing 9 is divided into several cavities 13 . In each cavity 13, a following hydraulic cylinder 5 is set and fixed. The lower end faces of the reinforcing ribs 10 are flush with the lower end faces of the side plates 11 and combined constitute a supporting surface following the housing. In Embodiment 2, the way that the following hydraulic cylinder 5 is installed on the following housing 9 and that the following housing 9 is installed on the bottom of the box girder 1 is the same as that of Embodiment 1, so it will not be repeated here.

[0049] Due to the need to support the upper structure, the following hydraulic cylinders 5 are usually used i...

Embodiment 3

[0051] see Figure 6 , In the present embodiment 3, the following housing 9 is roughly in the shape of a cuboid steel square tube, which is composed of four side plates 11 welded to each other. The outer edge of one end of the side plate 11 is welded with a flange 6 for bolting to the box girder 1, and the other end constitutes a supporting surface. The height of the side plate 11 is also the same as the minimum height of the jacking hydraulic cylinder 4 . The hollow inner cavity of the following housing 9 is used for fitting the following hydraulic cylinder 5 .

[0052] During installation, the following housing 9 and the following hydraulic cylinder 5 are respectively fixed to the box girder 1. First, the base of the following hydraulic cylinder 5 is bolted to the bottom of the box beam 1, and then the following housing 9 is set outside the following hydraulic cylinder 5. , and the flange 6 and the box girder 1 are bolted and fixed by bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com