High-nicotine tobacco extract, preparation method thereof and heat-not-burn cigarette

A technology of tobacco extract and high nicotine, applied in the field of tobacco, can solve the problem of high nicotine content in high nicotine tobacco extract, and achieve the effects of short time consumption, low temperature, and improving the content of aroma components and water-soluble sugars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

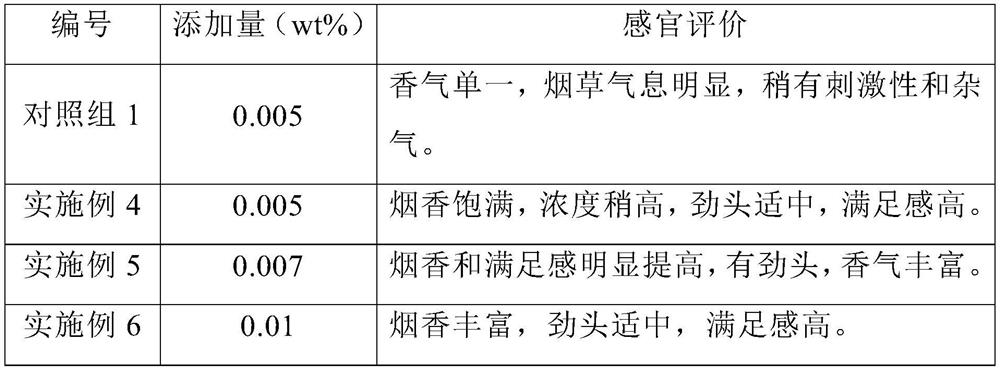

Examples

Embodiment 1

[0032] This embodiment discloses a method for preparing a high-nicotine tobacco extract from tobacco raw materials in Qujing, Yunnan. The specific steps are as follows:

[0033] (1) After pulverizing the raw material with a mass of m, pass through a 40-mesh sieve; add 0.3% m pectinase (enzyme activity: 50,000 U) and 0.2% m cellulase in water with a quality of 1.5 m (Enzyme activity: 100,000 U), mix with raw materials after uniform stirring, and carry out enzymolysis reaction; the time of enzymolysis reaction is 3 hours, and the temperature is 50°C.

[0034] (2) Mix the enzymatically hydrolyzed material with 7m ethanol solution (90%, v / v), extract at 55°C for 1 hour; separate solid from liquid after extraction, and filter the liquid to obtain tobacco extract.

[0035] (3) concentrating the tobacco extract under reduced pressure to a solid content of 60% at 65° C. to obtain a tobacco alcohol extract; the cooling temperature is 0° C. to recover ethanol.

[0036] (4) Alkalinizati...

Embodiment 2

[0040] This embodiment discloses a method for preparing a high-nicotine tobacco extract from tobacco raw materials in Zhaotong, Yunnan. The specific steps are as follows:

[0041] (1) after the raw material that quality is m is pulverized, cross 60 mesh sieves; In the water that quality is 2m, add the pectinase (enzyme activity: 50,000 U) that quality is 0.4% m and the cellulase ( Enzyme activity: 100,000 U), mix with raw materials after uniform stirring, and carry out enzymolysis reaction; the time of enzymolysis reaction is 2.5h, and the temperature is 55°C.

[0042] (2) Mix the enzymatically hydrolyzed material with 8m ethanol solution (95%, v / v), extract at 55°C for 2h; separate the solid and liquid after extraction, and filter the liquid to obtain tobacco extract.

[0043] (3) concentrating the tobacco extract under reduced pressure to a solid content of 60% at 70° C. to obtain a tobacco alcohol extract; the cooling temperature is 0° C. to recover ethanol.

[0044](4) Al...

Embodiment 3

[0048] This embodiment discloses a method for preparing a high-nicotine tobacco extract from tobacco raw materials in Zunyi, Guizhou. The specific steps are as follows:

[0049] (1) after the raw material that quality is m is pulverized, cross 40 mesh sieves; In the water that quality is 2m, add the pectinase (enzyme activity: 50,000 U) and the cellulase (enzyme activity: 50,000 U) and 0.5% m that quality is 0.5% m Enzyme activity: 100,000 U), mix with raw materials after uniform stirring, and carry out enzymolysis reaction; the time of enzymolysis reaction is 3 hours, and the temperature is 50°C.

[0050] (2) Mix the material after enzymolysis with 9m ethanol solution (95%, v / v), extract at 60° C. for 1 hour; separate solid and liquid after extraction, and filter the liquid to obtain tobacco extract.

[0051] (3) concentrating the tobacco extract at 65° C. under reduced pressure to a solid content of 60 percent to obtain tobacco ethanol extract; the cooling temperature is -5°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com