Extract for heat-not-burn cigarette and preparation method of extract

A heat-not-burn, extraction technology, applied in the field of tobacco, can solve the problem of high nicotine content, achieve the effect of small loss of aroma components, small pollution, and increase content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

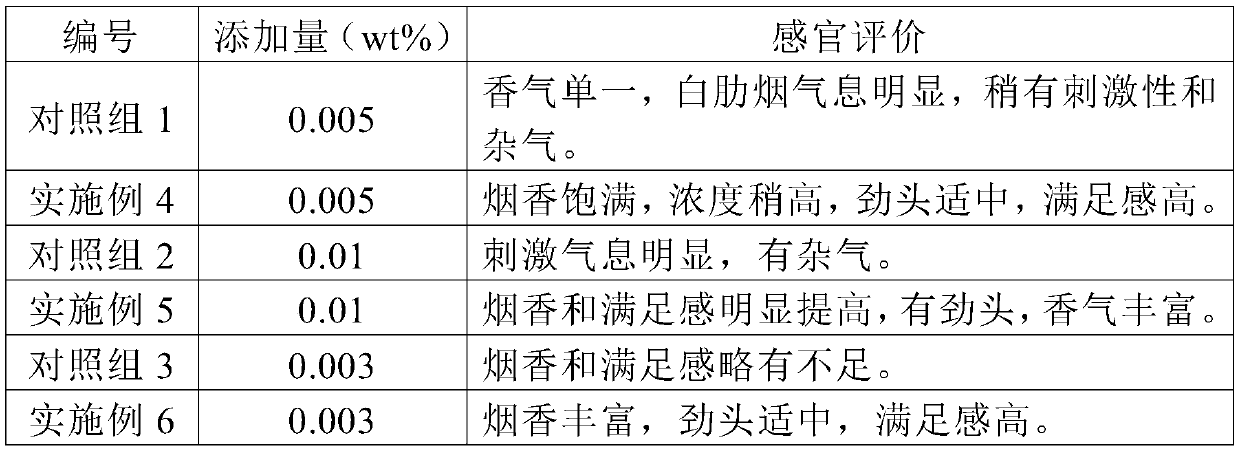

Examples

Embodiment 1

[0028] This embodiment discloses a method for preparing an extract for heat-not-burn cigarettes using Burley tobacco as a raw material. The specific steps are as follows:

[0029] (1) Extraction: after pulverizing the raw material with a mass of m, pass it through a 40-mesh sieve, mix it with an alcohol solution (90%, v / v) with a mass of 7 m, and extract at 55°C for 1 hour; after extraction, the solid-liquid separation, the liquid Filter to obtain tobacco extract.

[0030] (2) Concentration: the tobacco extract is concentrated under reduced pressure to a solid content of 60% at 60°C to obtain a tobacco alcohol paste; the cooling temperature is 0°C to recover the alcohol.

[0031] (3) Alkalinization extraction: add 2n NaOH solution (pH value 2) to n tobacco alcohol paste, stir for 5 min; then mix with 2n petroleum ether, extract for 1 h.

[0032] (4) Refining: the extract is separated, the organic phase is taken, and concentrated under reduced pressure at 50°C until no petrole...

Embodiment 2

[0035] This example discloses a method for preparing an extract for heat-not-burn cigarettes from tobacco raw materials in Zhaotong, Yunnan. The specific steps are as follows:

[0036] (1) Extraction: After pulverizing the raw material with a mass of m, pass through a 60-mesh sieve, mix with an alcohol solution (95%, v / v) with a mass of 8 m, and extract at 60° C. for 1.5 h; after extraction, solid-liquid separation, The liquid is filtered to obtain tobacco extract.

[0037] (2) Concentration: Tobacco extract is concentrated under reduced pressure at 65°C to a solid content of 70% to obtain tobacco alcohol paste; the cooling temperature is -10°C to recover alcohol.

[0038] (3) Alkalinization extraction: Add 3n NaOH solution (pH value 2) to tobacco alcohol paste with mass n, stir for 5 min; then mix with dichloromethane with mass n, and extract for 2 h.

[0039] (4) Refining: the extract is separated, the organic phase is taken, and concentrated under reduced pressure at 40°C ...

Embodiment 3

[0042] This example discloses a method for preparing an extract for heat-not-burn cigarettes from tobacco raw materials in Yuxi, Yunnan. The specific steps are as follows:

[0043] (1) Extraction: After pulverizing the raw materials with a mass of m, pass through a 40-mesh sieve, mix with an alcohol solution (80%, v / v) with a mass of 10 m, and extract at 60° C. for 1.5 h; after extraction, solid-liquid separation, The liquid is filtered to obtain tobacco extract.

[0044] (2) Concentration: the tobacco extract is concentrated under reduced pressure at 70°C to a solid content of 55% to obtain a tobacco alcohol paste; the cooling temperature is 0°C, and the alcohol is recovered.

[0045] (3) Alkalinization extraction: add 2n NaOH solution (pH value to 3) into tobacco alcohol paste with a mass of n, stir for 10 min; then mix with n-hexane with a mass of 2n, and extract for 1 h.

[0046] (4) Refining: the extract is separated, the organic phase is taken, and concentrated under re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com