A gas-sealed gas-saving tunnel furnace

A technology of hermetic sealing and tunnel furnace, which is applied in the field of tunnel furnace, can solve the problems of protective atmosphere leakage and waste, and achieve good energy saving and good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

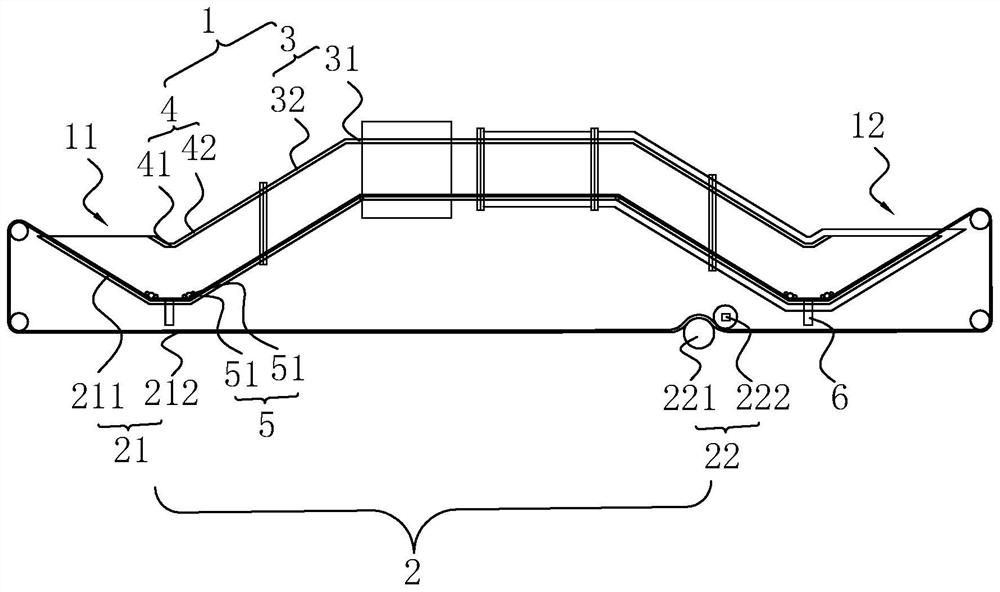

[0033] refer to figure 1 , the gas-sealed gas-saving tunnel furnace includes a furnace body 1 with an inlet channel 11 and an outlet channel 12 formed at the beginning and end, and a conveying device 2 passing through the interior of the furnace body 1. The furnace body 1 includes a high-temperature heating section 3 and connected to both ends of the high-temperature heating section 3. The height of the gas sealing section 4, the high temperature heating section 3 is higher than the height of the two gas sealing sections 4, and the height of the two gas sealing sections 4 is kept the same, so that the protective gas of light specific gravity can be filled in the high temperature heating section 3, and The high specific gravity protective gas can be filled in the gas sealing section 4, and the high specific gravity protective gas in the gas sealing section 4 can have a gas sealing effect on the light specific gravity protective gas in the high temperature heating section 3, redu...

Embodiment 2

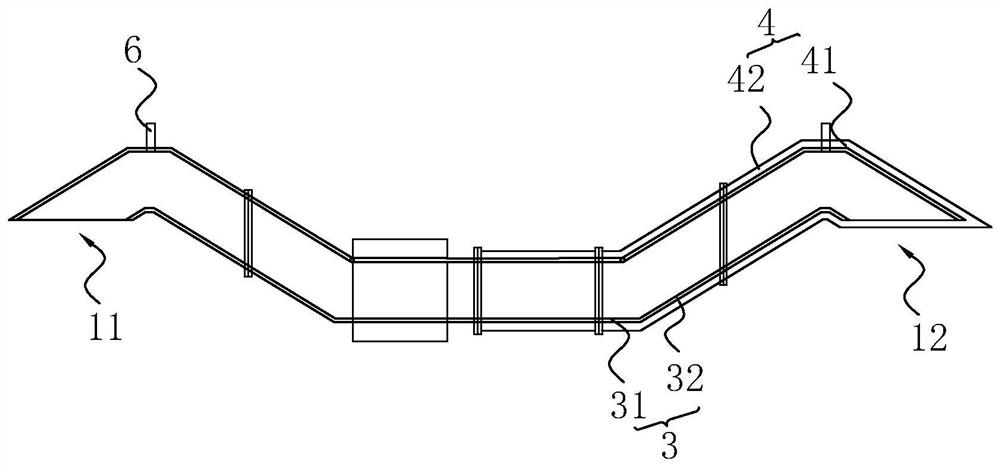

[0042] refer to figure 2 , the gas-sealed gas-saving tunnel furnace, the difference from Example 1 is that the height of the high-temperature heating section 3 is lower than the height of the gas-sealed section 4, so that the protective gas with high specific gravity is filled in the high-temperature heating section 3, and the light-specific gravity The protective gas can be filled in the gas sealing section 4, and the light specific gravity protective gas in the gas sealing section 4 can have a gas sealing effect on the high specific gravity protective gas in the high temperature heating section 3, reducing the overflow of the high specific gravity protective gas. Improve the solar term effect.

[0043] The implementation principle of Example 2 is as follows: the furnace body 1 is M-shaped as a whole. Before starting to use, a protective gas with a high specific gravity is filled into the high-temperature heating section 3, so that the oxygen in the high-temperature heating ...

Embodiment 3

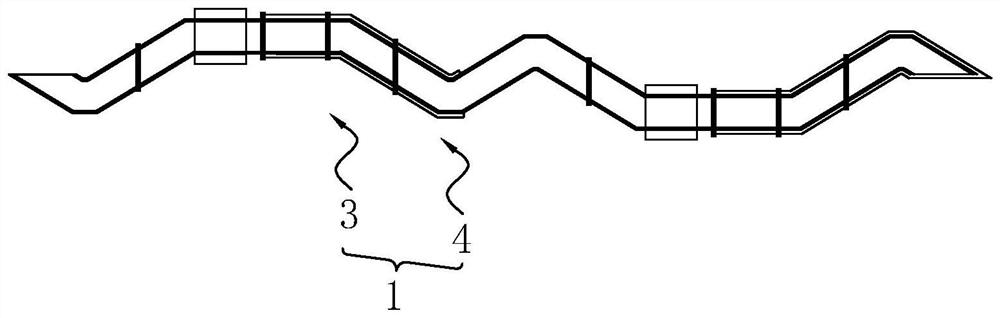

[0045] refer to image 3 , The gas-sealed gas-saving tunnel furnace differs from Embodiment 1 in that a plurality of furnace bodies 1 are provided and connected in sequence, so the furnace body 1 is a high-temperature heating section 3 and a gas-sealing section 4 arranged at intervals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com