Five-way plastic valve for drilling hole during gas extraction, and installation and use method thereof

A gas drainage and five-way technology, which is applied in the direction of multi-way valves, valve devices, gas discharge, etc., can solve the problems of poor corrosion resistance, high cost, and slow pipe connection speed, and achieve strong corrosion resistance and simple structure , the effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

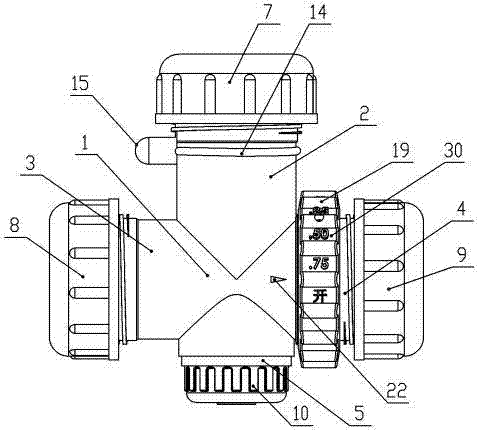

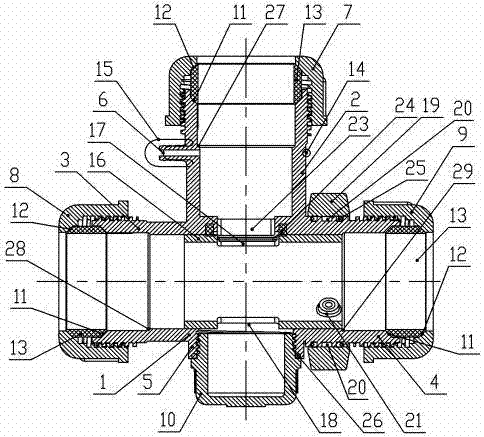

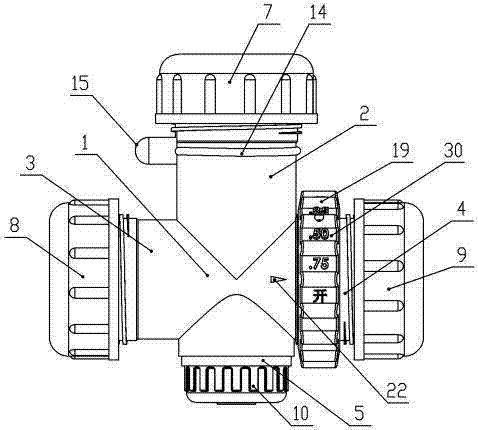

[0023] Such as figure 1 , figure 2 As shown, the five-way plastic valve for gas drainage drilling of the present invention includes a valve body 1, and the valve body 1 is provided with an upper connecting pipe joint 2, a left connecting pipe joint 3, a right connecting pipe joint 4, The lower dredging joint 5 and the gas measuring nozzle 6, wherein the upper connecting pipe joint 2, the left connecting pipe joint 3 and the right connecting pipe joint 4 are respectively screwed with an upper pipe clamp nut 7, a left pipe clamp nut 8 and a right pipe clamp nut 9 , the lower dredging joint 5 is screwed with a slag settler 10, the volume of the slag settler 10 inner cavity can be appropriately changed in volume and shape according to the actual situation; the upper connection pipe joint 2, the left connection pipe joint 3, and the right connection The inner axial direction of the pipe joint 4 is a structure with two different internal diameters, the inner diameter is small and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com