Fiber reinforced rubber sealing diaphragm forming method and equipment thereof

A technology of rubber sealing and fiber reinforcement, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of low shrinkage, low modulus, and high specific strength of fiber materials, so as to increase the interface bonding strength and improve The effect of glue rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

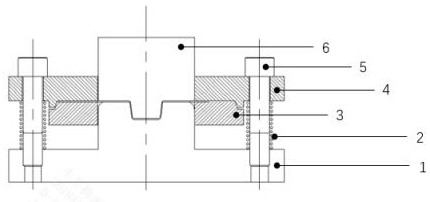

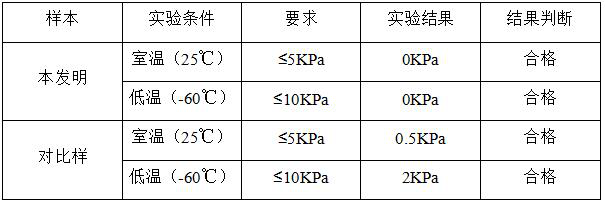

[0031] Lay a 0.1mm thick polyester fiber cloth on the test bench, evenly brush the water-based epoxy resin with a ratio of 1:20 on the fiber cloth, and dry it at room temperature for 30 minutes. Brush evenly with resorcinol-formaldehyde-latex (RFL adhesive) and dry for 2 minutes. Put the fiber cloth coated with glue flat on the preformed tooling, press it through the pressure plate, and then lightly lock it with the hexagon socket head screw and the compression spring, so that it has tightness in the vertical direction and can be tight in the horizontal and vertical directions. The amount of displacement, and then apply the vertical compression force through the pressure head tooling, so that the fiber cloth skeleton material has the specific "several" shape of the sealing template.

[0032] Gently move the formed skeleton material into a mold with a preheating temperature of 80°C, and then pre-embed a 0.05mm thick film, apply a pressure of 2000MPa through the vulcanizing mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com