Partial discharge comprehensive inspection instrument for high-voltage power equipment

A high-voltage power equipment, partial discharge technology, applied in the field of high-voltage power transmission and transformation, can solve the problems of a single detection instrument, input labor, limited detection range, etc., to achieve the effect of improving the inspection effect, avoiding safety accidents, and increasing the range of warnings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

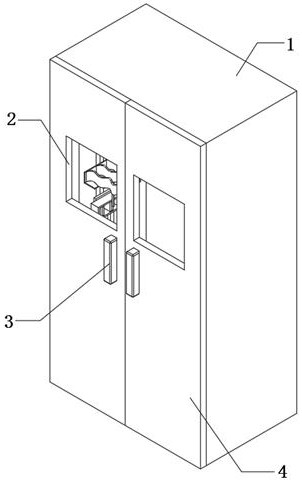

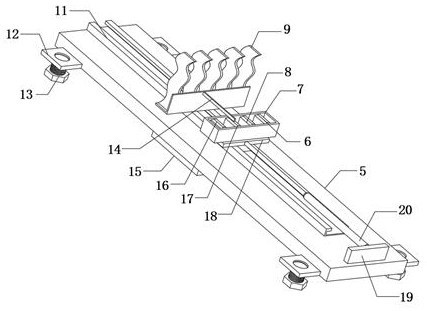

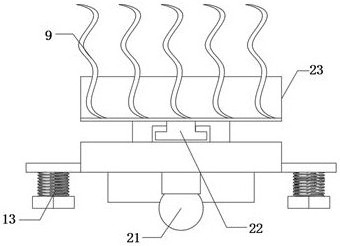

[0030] refer to Figure 1-3 , a comprehensive partial discharge inspection instrument for high-voltage power equipment, including a power distribution cabinet 1 and a mounting plate 5, the outer wall of one side of the mounting plate 5 is fixedly connected with a chute 11, and the inner wall of the chute 11 is slidably connected with a slider 22, the slider The outer wall of 22 is fixedly connected with a slide plate 18, the outer wall of the slide plate 18 is fixedly connected with a fixed frame 7, and the inner wall of the fixed frame 7 is fixedly connected with a TEV sensor 6, a UHF sensor 8, a non-contact AE sensor 16 and a contact AE sensor 17 , the outer wall of the contact AE sensor 17 is fixedly connected with a conductive rod 14, and the top outer wall of the conductive rod 14 is fixedly connected with a conductive frame 23, and the top outer wall of the conductive frame 23 is fixedly connected with a flexible conductive plate 9 equidistantly. A variety of measurement...

Embodiment 2

[0036] refer to Figure 1-4 , a comprehensive partial discharge inspection instrument for high-voltage power equipment, including a power distribution cabinet 1 and a mounting plate 5, the outer wall of one side of the mounting plate 5 is fixedly connected with a chute 11, and the inner wall of the chute 11 is slidably connected with a slider 22, the slider The outer wall of 22 is fixedly connected with a slide plate 18, the outer wall of the slide plate 18 is fixedly connected with a fixed frame 7, and the inner wall of the fixed frame 7 is fixedly connected with a TEV sensor 6, a UHF sensor 8, a non-contact AE sensor 16 and a contact AE sensor 17 , the outer wall of the contact AE sensor 17 is fixedly connected with a conductive rod 14, and the top outer wall of the conductive rod 14 is fixedly connected with a conductive frame 23, and the top outer wall of the conductive frame 23 is fixedly connected with a flexible conductive plate 9 equidistantly. A variety of measurement...

Embodiment 3

[0043] refer to Figure 1-4 , a comprehensive partial discharge inspection instrument for high-voltage power equipment, including a power distribution cabinet 1 and a mounting plate 5, the outer wall of one side of the mounting plate 5 is fixedly connected with a chute 11, and the inner wall of the chute 11 is slidably connected with a slider 22, the slider The outer wall of 22 is fixedly connected with a slide plate 18, the outer wall of the slide plate 18 is fixedly connected with a fixed frame 7, and the inner wall of the fixed frame 7 is fixedly connected with a TEV sensor 6, a UHF sensor 8, a non-contact AE sensor 16 and a contact AE sensor 17 , the outer wall of the contact AE sensor 17 is fixedly connected with a conductive rod 14, and the top outer wall of the conductive rod 14 is fixedly connected with a conductive frame 23, and the top outer wall of the conductive frame 23 is fixedly connected with a flexible conductive plate 9 equidistantly. A variety of measurement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com