An industrial-grade intelligent surface defect detection method

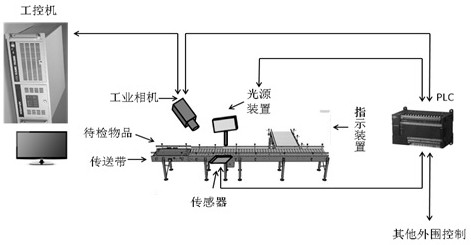

A defect detection, industrial-grade technology, applied in the industrial application field of deep learning technology, can solve problems such as difficult to meet the needs of the industrial field, small sample size and resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

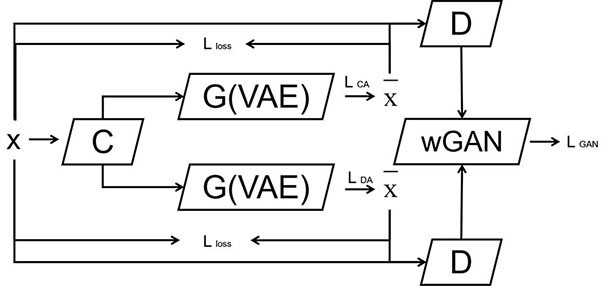

[0065] like figure 2 As shown, in the first half of the training stage of the improved GAN network, the conversion of paired images is completed by referring to pix2pix for training (pix2pix aims to solve the problem of large image resolution); the L1 distance is calculated as the absolute difference of the first dimension value plus the absolute value of the second-dimensional difference, and the L2 distance is calculated by adding the square of the first-dimensional difference plus the square of the second-dimensional difference, summing, and then rooting. Compared with the L2 distance, the L1 distance retains more information at the edge position, and the L1 distance is more suitable for less blurred images than the L2 distance. Here, the L1 distance is used to characterize their similarity. Combining the objective function and loss function of GAN, please define the first dimension difference and the second dimension:

[0066] Definition of first dimension difference: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com