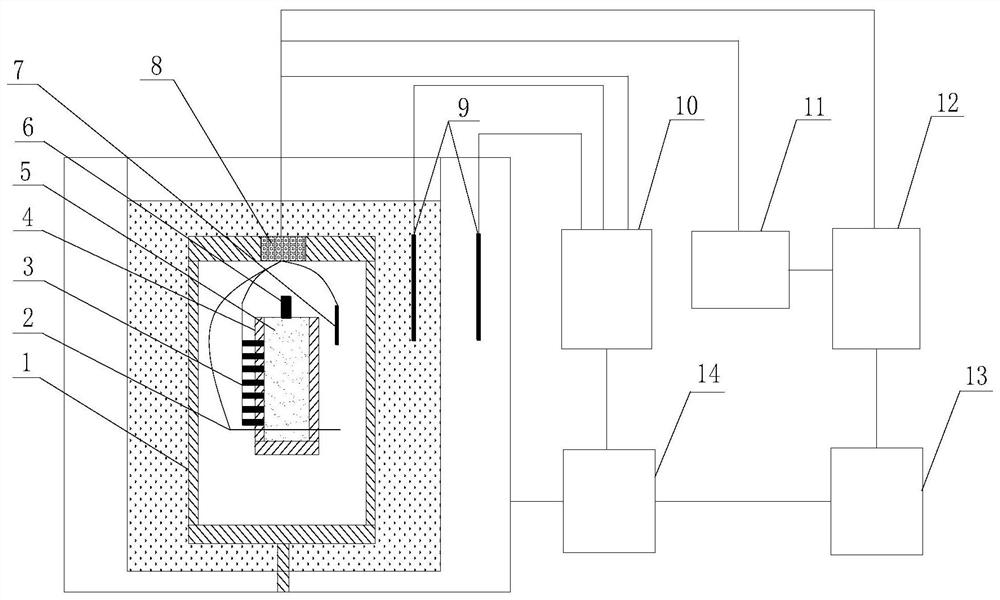

A multi-parameter simultaneous measurement method for the detonation performance of condensed phase high-energy explosives

A technology for high-energy explosives and detonation performance, which is applied in the fields of material explosiveness, ammunition, and ammunition tests. The effect of simple preparation and improved measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

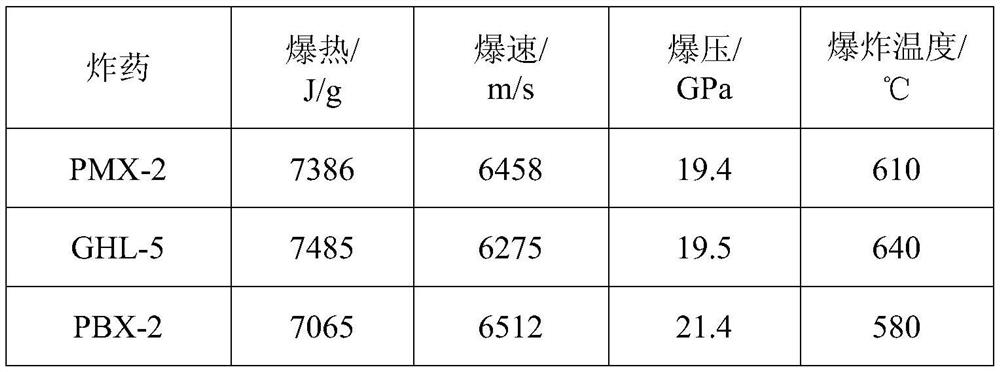

[0034] This embodiment is the measurement of the detonation performance of PMX-2 explosives. The grain 5 used is 10 grains of Φ5mm×5mm superimposed, and the density is 1.85g / cm 3 , the housing 4 has a length of 60mm, an inner diameter of 5mm, and a wall thickness of 2mm. There are 10 positioning holes with a diameter of 0.8mm, the hole spacing is 5mm, and the diameter of the fiber optic probe 3 is 0.8mm. The test method includes the following steps:

[0035] (1) PMX-2 explosives are made into a cylindrical grain 5, the grain 5 is formed by superimposing 10 grains of Φ5mm×5mm, and the prepared grain 5 is stored in the sample temporary storage area;

[0036] (2) Check and debug manganin piezoresistive sensor 2, fiber optic probe 3, temperature sensor 7, platinum resistor 9, temperature acquisition system 10, photodetector 11, data acquisition instrument 12, data processing system 13 and calorimetry system 14 , to make it reach the normal working state, turn off the power;

[00...

Embodiment 2

[0050] This example is the measurement of the detonation performance of GHL-5 explosive. The grain 5 used is 12 grains of Φ8mm×8mm superimposed, and the density is 1.85g / cm 3 , the housing 4 has a length of 120mm, an inner diameter of 8mm, and a wall thickness of 3mm. There are 12 positioning holes with a diameter of 0.9mm, the hole spacing is 8mm, and the diameter of the fiber optic probe 3 is 0.9mm. The test method includes the following steps:

[0051] (1) GHL-5 explosive is made into a cylindrical grain 5, which is formed by superimposing 12 grains of Φ8mm×8mm, and the prepared grain 5 is stored in the sample temporary storage area;

[0052] (2) Check and debug manganin piezoresistive sensor 2, fiber optic probe 3, temperature sensor 7, platinum resistor 9, temperature acquisition system 10, photodetector 11, data acquisition instrument 12, data processing system 13 and calorimetry system 14 , to make it reach the normal working state, turn off the power;

[0053] (3) Pac...

Embodiment 3

[0066] This embodiment is the measurement of the detonation performance of PBX-2 explosives. The used grain column 5 is formed by superimposing 15 grain columns of Φ10mm×10mm, and the density is 1.82g / cm 3 , the housing 4 has a length of 180mm, an inner diameter of 10mm, and a wall thickness of 4mm. There are 15 positioning holes with a diameter of 1.0mm, the hole spacing is 10mm, and the diameter of the fiber optic probe 3 is 1.0mm. The test method includes the following steps:

[0067] (1) The PBX-2 explosive is made into a cylindrical grain 5, the grain 5 is formed by superimposing 15 grains of Φ10mm×10mm, and the prepared grain 5 is stored in the sample temporary storage area;

[0068] (2) Check and debug manganin piezoresistive sensor 2, fiber optic probe 3, temperature sensor 7, platinum resistor 9, temperature acquisition system 10, photodetector 11, data acquisition instrument 12, data processing system 13 and calorimetry system 14 , to make it reach the normal working...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com