Washing and spin-drying device for fiber processing

A fiber and cleaning box technology, applied in the direction of drying gas arrangement, drying solid materials without heating, drying, etc., can solve problems such as low work efficiency, troublesome operation, and inconvenient salvage, so as to improve the effect and efficiency, facilitate salvage, The effect of improving practicality and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

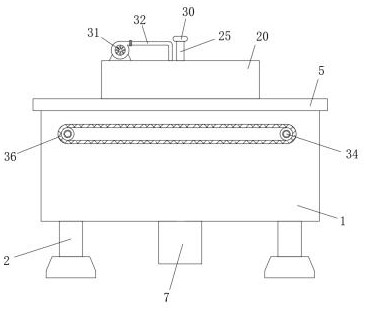

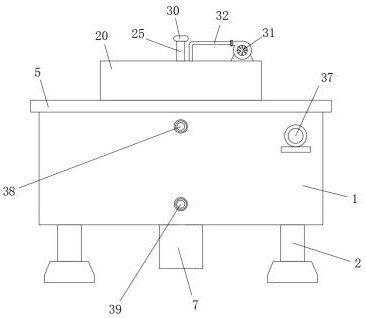

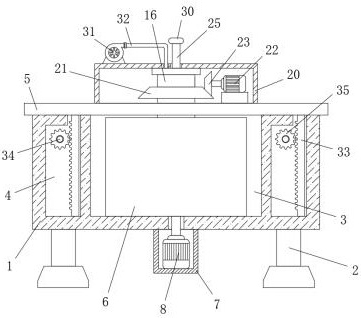

[0034] refer to Figure 1-10 , a fiber processing cleaning and drying device, comprising a cleaning box 1, the four corners of the bottom outer wall of the cleaning box 1 are fixedly connected with support legs 2, the inside of the cleaning box 2 is provided with a cleaning chamber 3, and the top of the cleaning chamber 3 is The opening is set, the top of the cleaning box 1 is in contact with the cover plate 5, and the inner wall of the bottom of the cleaning chamber 3 is rotatably connected to the cleaning cylinder 6. The inner wall of the bottom of the bottom is rotatably connected with a mixing drum 10, the top and bottom of the mixing drum 10 are respectively open and closed, and the inner wall of the cleaning drum 6 is vertically slidably connected with a lifting plate 11, and the bottom of the lifting plate 11 is connected to the bottom inner wall of the cleaning tube 6. contact with each other and have a through hole 12, and one side of the mixing drum 10 runs through t...

Embodiment 2

[0036] Further improved on the basis of embodiment one:

[0037] In the present invention, the bottom outer wall of the cleaning box 1 is fixedly connected with a protective box 7, and the first motor 8 is fixedly installed in the protective box 7. Rotationally connected, the cleaning cylinder 6 can be driven to rotate by starting the first motor 8, so as to achieve the effect of drying.

[0038] In the present invention, the top of the lifting plate 11 is provided with a groove 13, and the inner wall of the bottom of the groove 13 is annularly evenly provided with a plurality of second water holes 14. Through the setting of the groove 13 on the top of the lifting plate 11, it is convenient for the material to be processed. Centralized collection.

[0039] In the present invention, the outer wall of the mixing drum 10 is provided with four chutes 15 in an annular equidistant manner, and the bottom of the transmission cylinder 16 is provided with four sliding bars 17 in an ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com