High-efficiency plate cutting device for producing and processing low-voltage switch cabinet

A low-voltage switchgear, high-efficiency technology, applied in the field of high-efficiency cutting device for low-voltage switchgear production and processing, can solve the problems of plate cutting deviation, prone to sliding deviation, affecting quality, etc., and achieve the effect of stable cutting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

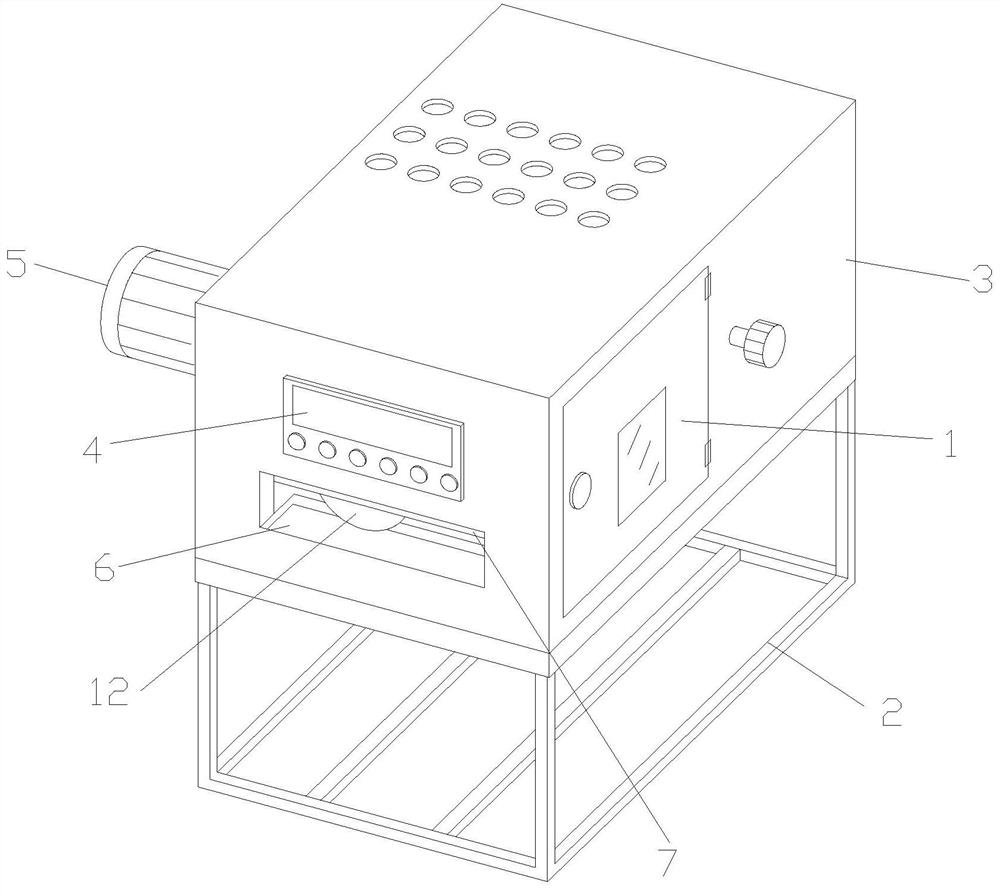

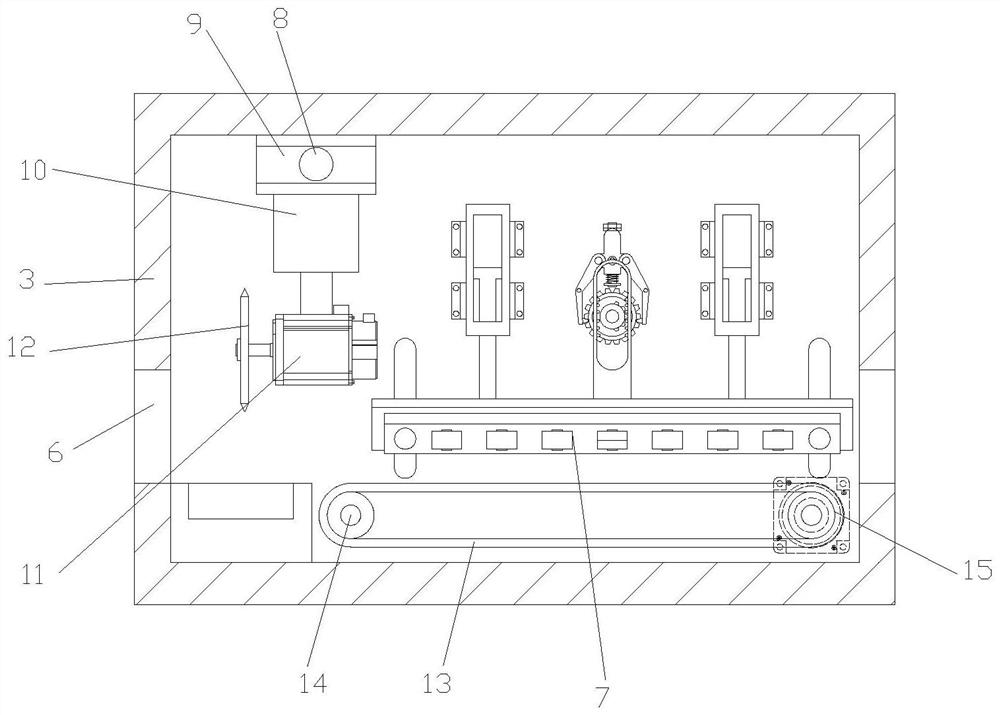

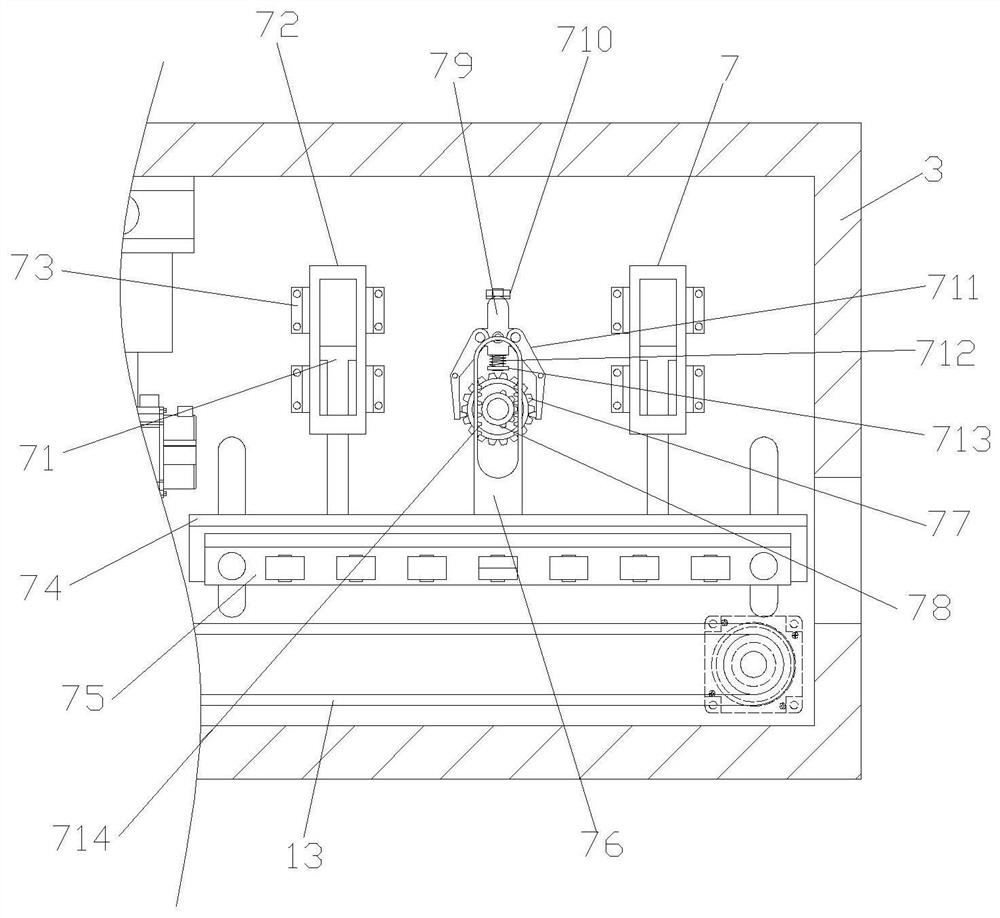

[0026] see figure 1 with figure 2 , the present invention provides a high-efficiency panel cutting device for the production and processing of low-voltage switchgear through improvement, including a switch door 1 and a bracket 2, the switch door 1 is hinged on the rear end surface of the panel cutting room 3, and the bracket 2 is installed on the bottom end surface of the panel cutting room 3, Cutting chamber 3 is provided with opening 6 in the middle and lower part of the left and right ends, and controller 4 and first motor 5 are respectively installed on the top of the left end surface of cutting chamber 3 and the left side of front end surface, and the bottom of cutting board chamber 3 inner side front surface is provided with through hole, and through The size of the hole is matched with the two-way screw mandrel 752, which is convenient to use after the two-way screw mandrel 752 is moved vertically. The output shaft at the rear end of the first motor 5 passes through th...

Embodiment 2

[0031] The present invention provides a high-efficiency panel cutting device for the production and processing of low-voltage switchgear through improvement. A transparent plastic plate is embedded in the rear end surface of the switch door 1, which is convenient for observing the working conditions in the panel cutting room 3 through the transparent plastic plate. The inside of the bracket 2 The bottom is provided with reinforcing rods, and two reinforcing rods are symmetrically arranged at the front and rear ends of the inner bottom of the bracket 2, so that the support of the bracket 2 is more stable.

[0032] The present invention provides a high-efficiency panel cutting device for low-voltage switchgear production and processing through improvement, and its working principle is as follows;

[0033] First, adjust the vertical height of the U-line guide plate 74 and the L-shaped limit plate 751 through the actual thickness of the plate, and the sleeve 7101, the transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com