Oak plug raw material rapid manufacturing device

A technology for making devices and cork, which is applied in the direction of cork machining, mechanical equipment, etc., and can solve the problems of residual oak veneer, waste, waste and rapid production of devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

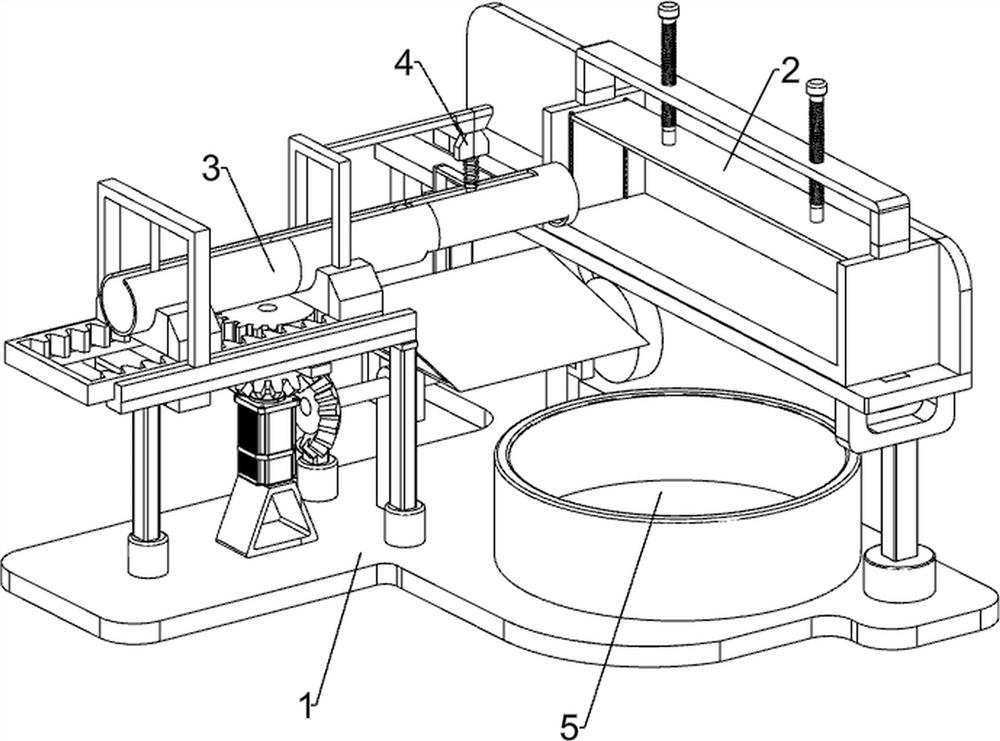

[0049] A rapid production device for cork raw materials, such as figure 1 As shown, it includes an installation frame 1 , a clamping mechanism 2 and a take-out mechanism 3 . The right side of the top of the installation frame 1 is provided with a clamping mechanism 2 , and the left side of the top of the installation frame 1 is provided with a take-out mechanism 3 .

[0050] When it is necessary to take out the raw materials for making the cork from the oak bark, the staff can put the oak bark into the clamping mechanism 2, put the collection box in the middle of the installation frame 1, and then turn the inner part of the clamping mechanism 2 to clamp the oak cork. Tighten, start the take-out mechanism 3 to work, and at the same time manually push the clamp mechanism 2 to work intermittently, the take-out mechanism 3 and the clamp mechanism 2 cooperate with each other to take out the cork material from the oak skin, and then drop it into the collection box to remove the cork....

Embodiment 2

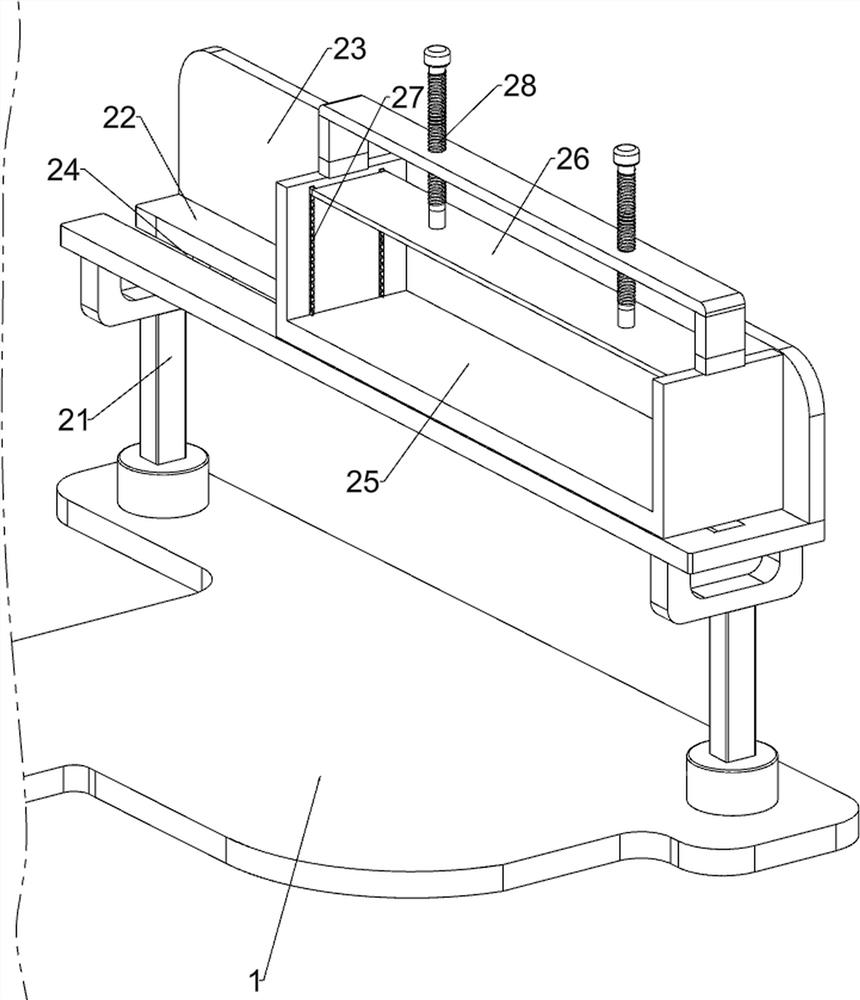

[0052] On the basis of Example 1, as figure 2 As shown, the clamping mechanism 2 includes a first mounting column 21, a mounting plate 22, a baffle plate 23, a clamping plate 25, a clamping plate 26, a first spring 27 and a screw rod 28. The top right side of the mounting frame 1 is provided with front and rear The first mounting post 21, a mounting plate 22 is connected between the top of the first mounting post 21, a baffle plate 23 is provided on the right side of the top of the mounting plate 22, a chute 24 is opened in the middle of the mounting plate 22, and the mounting plate 22 is slidably provided with The clamping plate 25, the clamping plate 26 is slidably connected between the inner walls of the clamping plate 25, the bottom of the clamping plate 26 is provided with a first spring 27, the end of the first spring 27 is connected with the inner wall of the clamping plate 25, and the clamping plate 26 is clamped. The top of the plate 25 is connected with a screw 28 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com