3D printer slice contour path planning algorithm

A 3D printer and path planning technology, applied in manufacturing auxiliary devices, processing data acquisition/processing, additive processing, etc., can solve problems such as shortening printing time, achieve shortening printing time, improve 3D printing efficiency, and achieve the best operating effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions in the embodiments of the present invention will be described clearly and in detail below with reference to the drawings in the embodiments of the present invention.

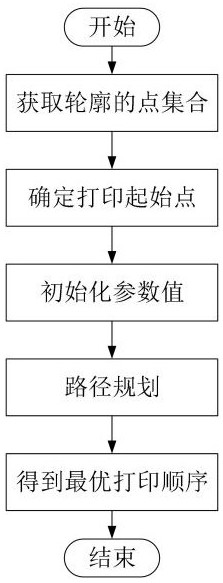

[0013] Such as figure 1 As shown, the present invention provides a 3D printer slicing contour path planning algorithm, comprising the following steps: first, an optimized shortest distance algorithm is used to determine the starting point of each closed loop contour in the slicing process, as the connection point of the 3D printing sequence, The goal should be to keep the distance between each starting point as short as possible. Then the single variable method is used to determine the initial parameter value of the ant colony algorithm. Finally, the ant colony algorithm and genetic algorithm are combined, and the improved ant colony algorithm is used to plan the path of the determined printing starting point, and the optimal printing path is obtained.

[0014] The specific steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com