Ultraviolet curing offset printing process capable of printing plane bas-relief effect

An offset printing process and bas-relief technology, which is used in the printing, printing process, and post-processing of printing special varieties of printed matter. Printing and other issues, to achieve the effect of novel and scientific and reasonable process design, novel and simple process design, and low printing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0019] refer to figure 1 , propose an embodiment of a UV-curable offset printing process capable of printing a flat bas-relief effect of the present invention, comprising the following process steps:

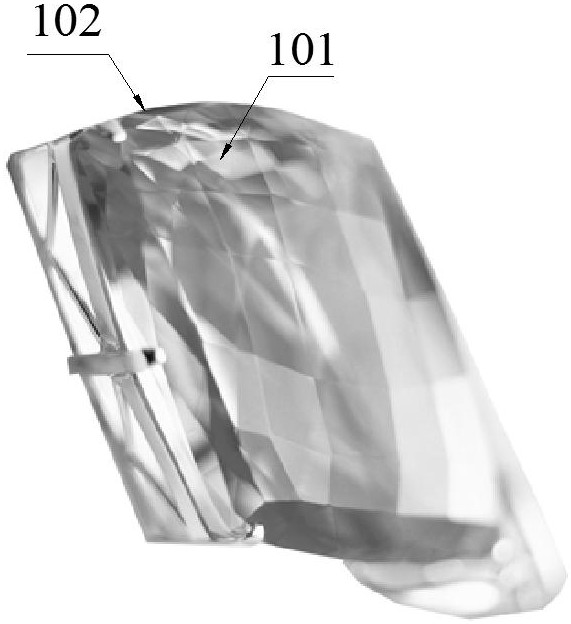

[0020] A, design bas-relief pattern and make artwork: design bas-relief pattern and make the artwork with described bas-relief pattern by the design software of computer, bas-relief pattern comprises embossment part 101, the outline protruding than relief part 101 Line section 102;

[0021] B. Select a suitable offset printing machine and design the color sequence: the offset printing machine includes a paper feeding mechanism, a paper delivery mechanism, a base with a transmission mechanism between the paper feeding mechanism and the paper delivery mechanism, and a base on the base Several printing seats, the printin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com