Powdery fuel preheating gas generator and corresponding powdery fuel boiler

A pulverized fuel and generator technology, which is applied in the direction of granular/powdered fuel gasification, etc., can solve the problems that material balance is not easy to establish, material balance is not easy, and the operating elastic space is small, so as to achieve easy operation and improve safety and reliability The effect of large flexibility and operation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

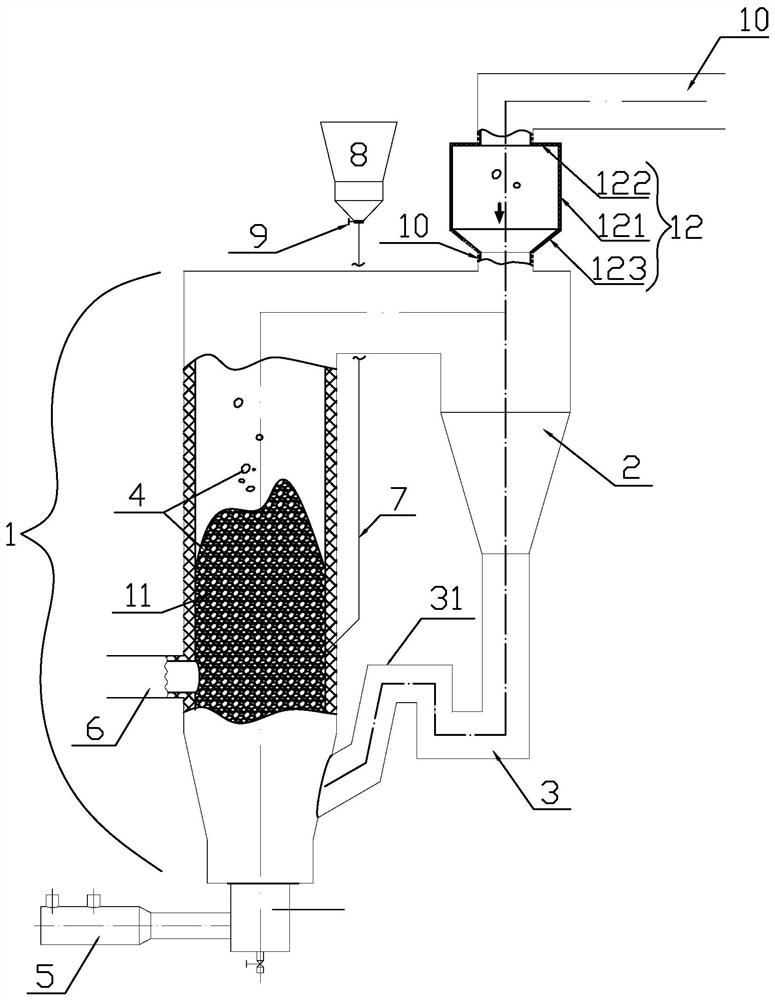

[0027] Implementation mode one: if figure 1 As shown, the pulverized fuel preheating gas generator of the present invention includes a preheating combustion chamber 1, a gas-solid separator 2 and a feeder 3, and the middle and lower part of the preheating combustion chamber 1 is provided with a fluidized bed 11 structure, and its interior The bottom material 4 of the fluidized bed is stored. The bottom of the preheating combustion chamber 1 is in the shape of an inverted cone. There are powder fuel feed pipe 6 and fluidized bed bottom feed pipe 7, the top of the fluidized bed bottom feed pipe 7 is provided with a feed hopper 8, and is provided with a feed valve 9, the gas-solid separator 2 is cyclone separation The gas-solid separator 2 is provided with an inlet, a lower solid outlet and a top gas outlet, the inlet of the gas-solid separator communicates with the top of the preheating combustion chamber 1, and the lower solid outlet of the gas-solid separator 2 is connected to...

Embodiment approach 2

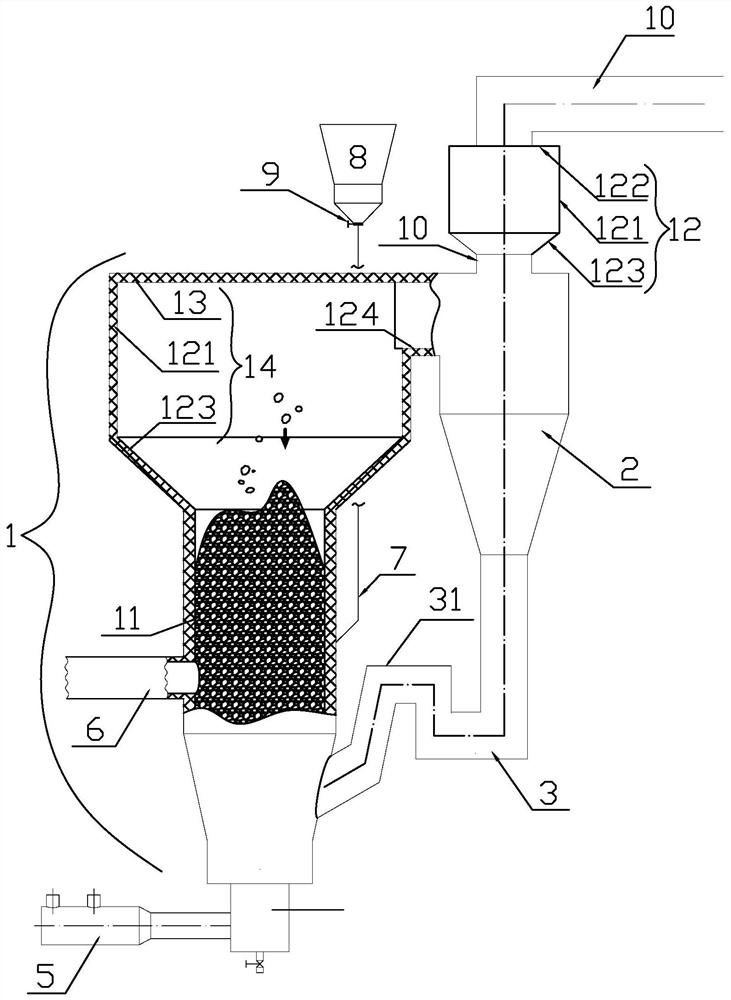

[0029] Implementation mode two: if figure 2 As shown, the upper part of the preheating combustion chamber 1 is also provided with a top sealing plate 13, an enlarged shell 121 and an inverted cone-shaped transition section 123. The expanded shell 121 is cylindrical, and its top side wall is provided with an air outlet Groove 124, the outer edge of the top sealing plate 13 is welded on the upper edge of the expansion shell 121 and the upper edge of the side wall of the air outlet groove 124, the top sealing plate 13 and the air outlet groove 124 form an air outlet, and pass through the air outlet Connected with the inlet of the gas-solid separator 2, the lower edge of the expanded casing 121 is welded to the outer edge of the large end of the inverted cone-shaped transition section 123, and the outer edge of the small end of the inverted-cone tubular transition section 123 is connected to the preheating combustion chamber 1. On the side wall of the fluidized bed 11 in the midd...

Embodiment approach 3

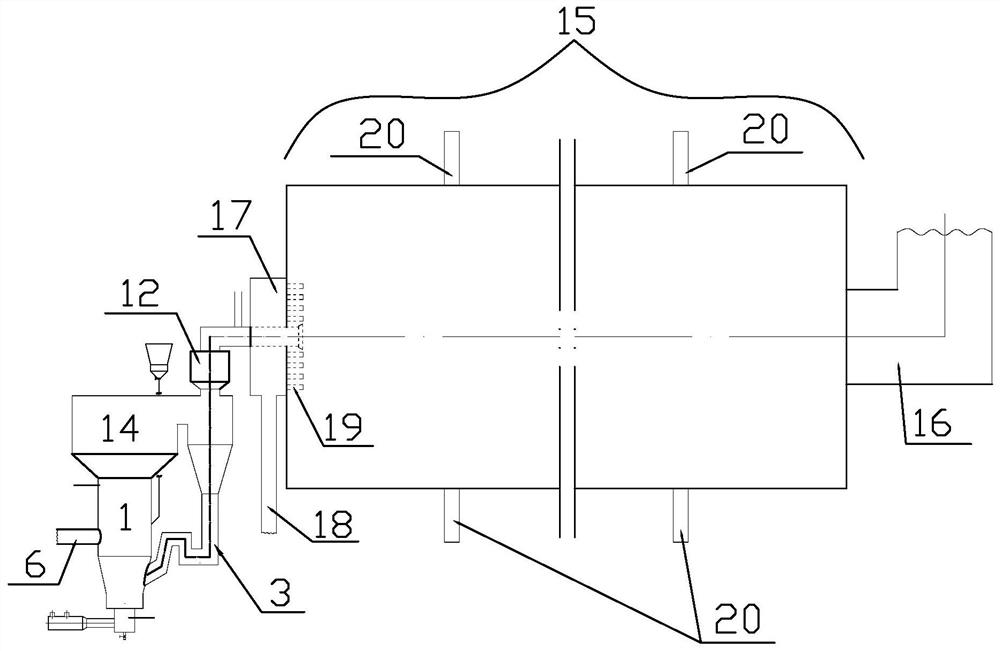

[0030] Implementation mode three: if image 3 As shown, the powder fuel horizontal combustion boiler of the present invention includes a horizontal boiler body 15, one end of the horizontal boiler body 15 is a feed end, the feed end is provided with a feed port, and the other end is provided with a tail flue 16, which The feature is that: the center of the side wall of the feed end of the horizontal boiler body 15 is provided with a secondary air box 17, and the exterior of the secondary air box 17 communicates with the secondary air pipe 18, and the interior of the horizontal boiler body 15 is provided with multiple The secondary air nozzle 19 connected to the secondary air box 17 is connected to the pulverized fuel preheating burner described in the first or second embodiment, omitted.

[0031] Implementation mode four: if image 3 As shown, the side wall of the horizontal boiler body 15 is provided with a plurality of embering air pipes 20, the above-mentioned embering air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com