Automatic weft detection and pirn feeding device for sisal yarn loom

A loom and sliver technology, which is applied in looms, textiles, computer control, etc., can solve problems affecting the appearance and quality of linen, problems such as the inability of the weft to be pushed into the weft shuttle chamber, missing and overlapping weft yarns of linen, etc., to achieve improved Production efficiency and economic benefits, relief of mental stress, and less weft ends in selvage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

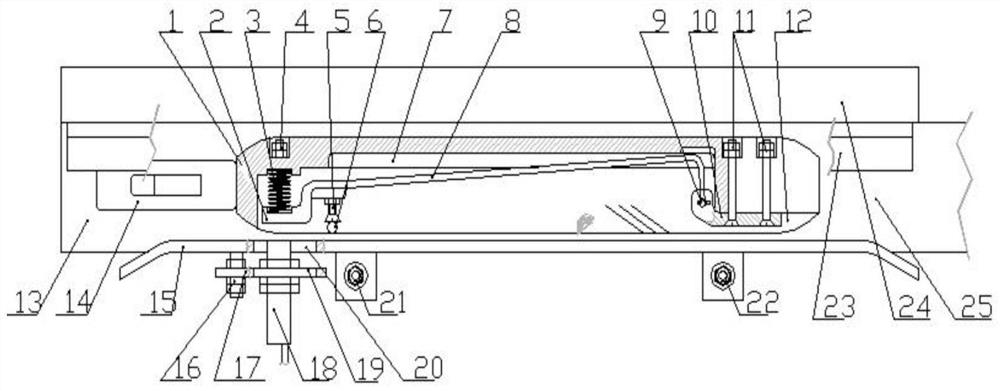

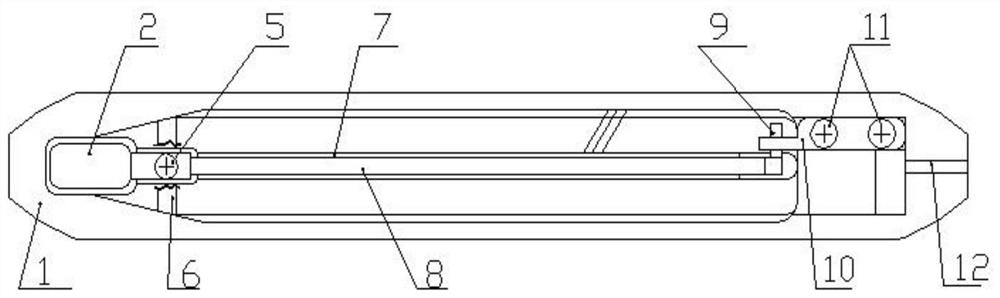

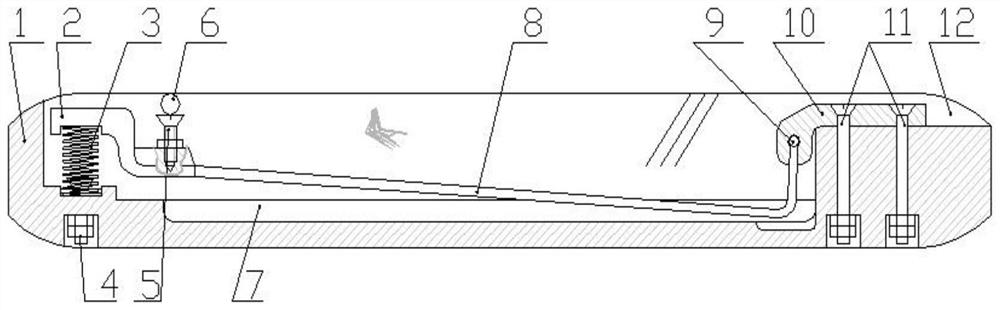

[0020] The technical solutions in the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] Some explanations among the present invention:

[0022] 1. "Shuttle bed" is an idiomatic term, and the technical term is "sley" in loom books.

[0023] 2. The "inner" and "outer" sides mentioned here are relative terms. The "inside" side points to the inside of the component, which may be the bottom plate or the inside of the machine, and the "outside" side points to the outside or the outside of the machine or the component. Taking the weft shuttle as an example, the cavity bottom plate facing the weft shuttle is the "inner" side, and the cavity mouth facing the weft shuttle is the "outside" side. Another example is that the outside of the variable conduction rod is provided with a limit screw, and the "outside" here is pointing to that side of the weft shuttle cavity notch.

[0024] 3. The working state of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com