Threader and industrial sewing machine applying same

A threader, sewing machine technology, applied in sewing machine components, sewing machine protection devices, sewing equipment and other directions, can solve problems such as waste of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

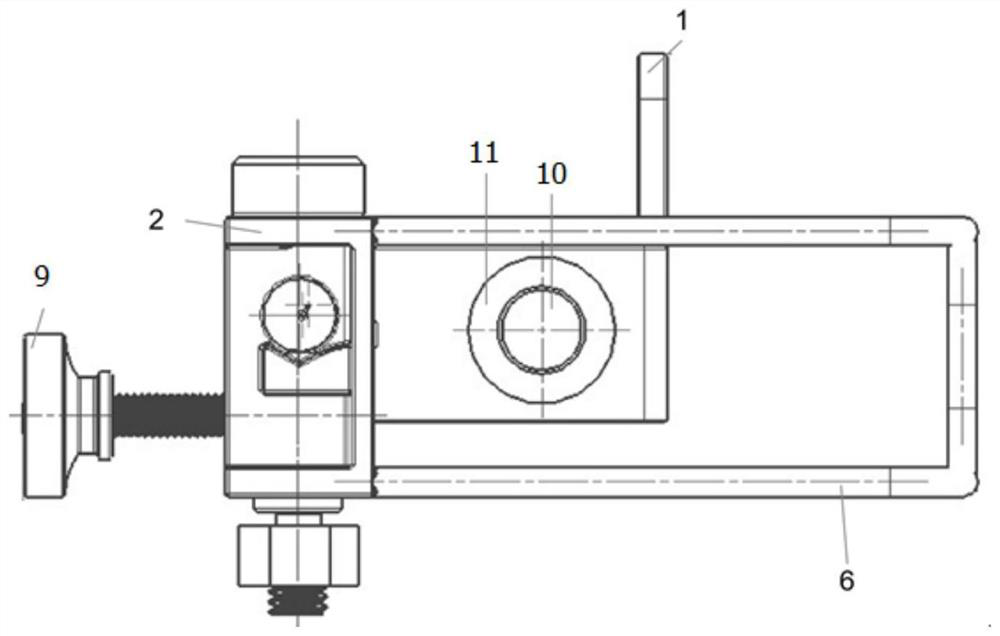

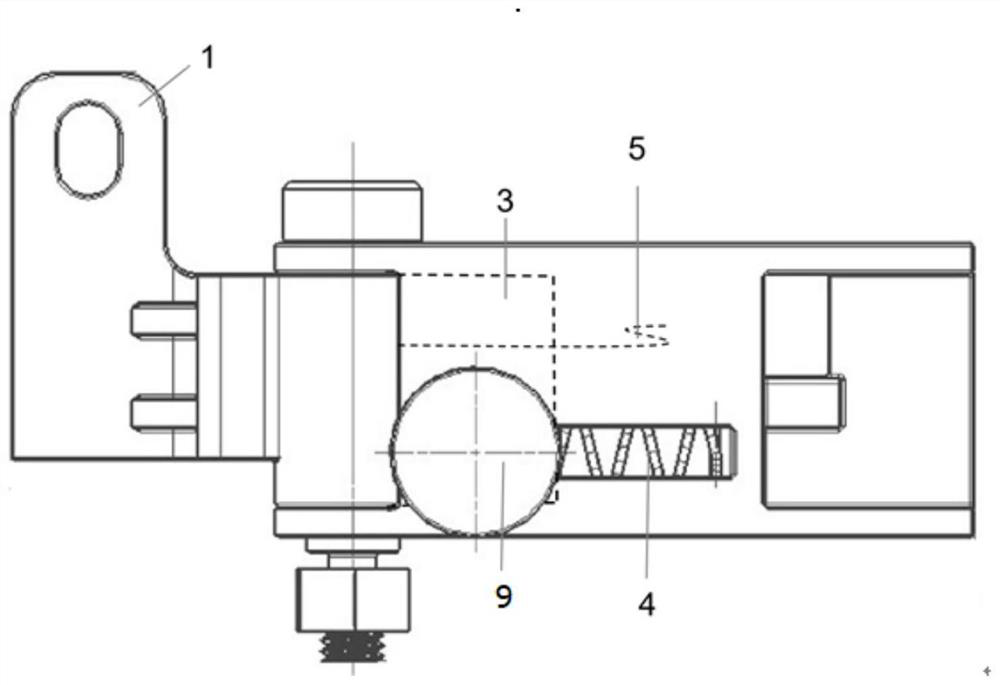

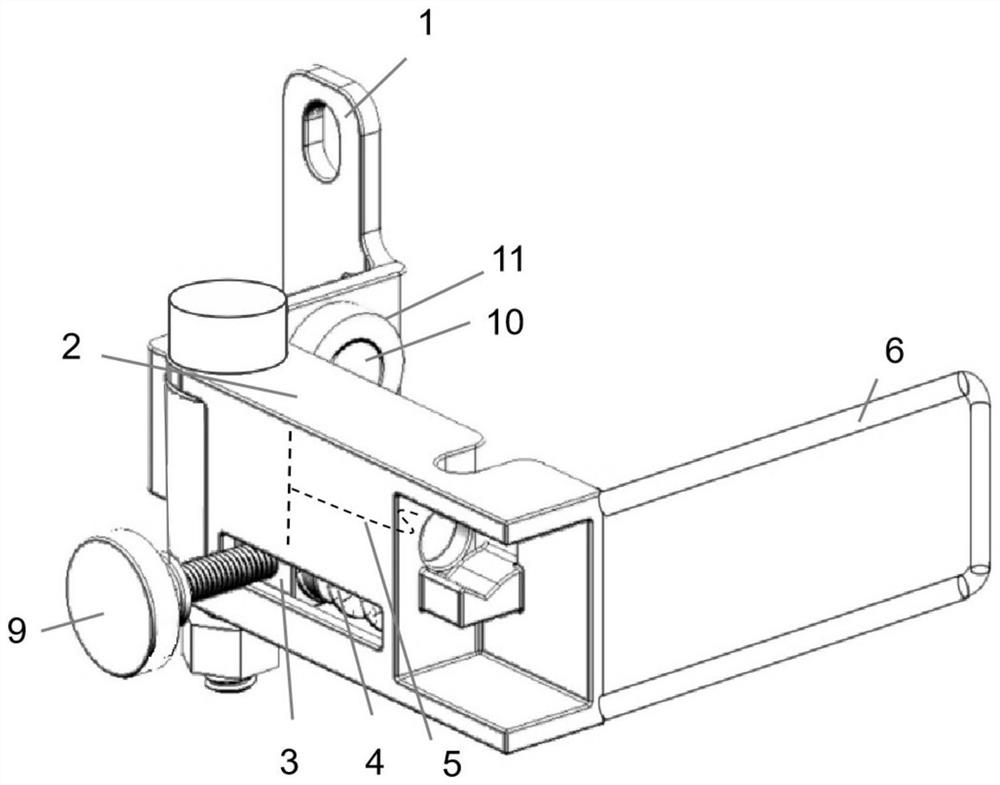

[0024] A sewing machine threader such as Figure 1-3 As shown, the fixed seat 1 is included, and the threader main body 2 is arranged on the fixed seat 1 with the fixed seat 1 as a reference. The fixed seat 1 is set as a "Z" shape, and is divided into a fixed plate body for fixing on an external sewing machine, and a connecting plate body perpendicular to the fixed plate body. The part is connected to the main body 2 of the threader through a rotating pair. The rotating pair in this embodiment uses a plug screw as a connecting piece, which runs through the side of the main body 2 of the threader and the bent edge of the fixing seat 1. Tighten the hexagonal nut at the end as a fastener, so that the main body 2 of the threader can be set in rotation with the fixed base 1 as the movement reference.

[0025] like image 3 As shown, the angle range of the threader body 2 rotating around the rotary pair is 0-90°, and the initial position of the threader body 2 is the position perp...

Embodiment 2

[0032] An industrial sewing machine, which is applied with the sewing machine threader of Embodiment 1, wherein a triangular support is set at the turning point of the fixing seat 1 of the sewing machine threader as a rib plate, so as to reduce the shaking caused by the rotation of the threader main body 2 and enhance the stability of the threader sex; such as Figure 4 As shown, the fixed plate body of the fixed seat 1 is used as one end of the connection, and is connected to the end of the presser foot bar 8 of the lockstitch sewing machine.

[0033] When the sewing machine was not broken, the threader main body 2 was in an open state, that is, the threader main body 2 was perpendicular to the connecting plate body of the holder 1, and the U-shaped guard finger 6 on the threader was used to block the fingers. In order to prevent the sewing machine operator from putting his finger under the sewing machine needle by mistake during operation. What threader main body 2 played t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com