Dyeing device for textile fabric processing

A dyeing device and technology for textile fabrics, applied in textile processing machine accessories, equipment configuration for processing textile materials, processing of textile materials, etc., can solve the problem of high cost and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

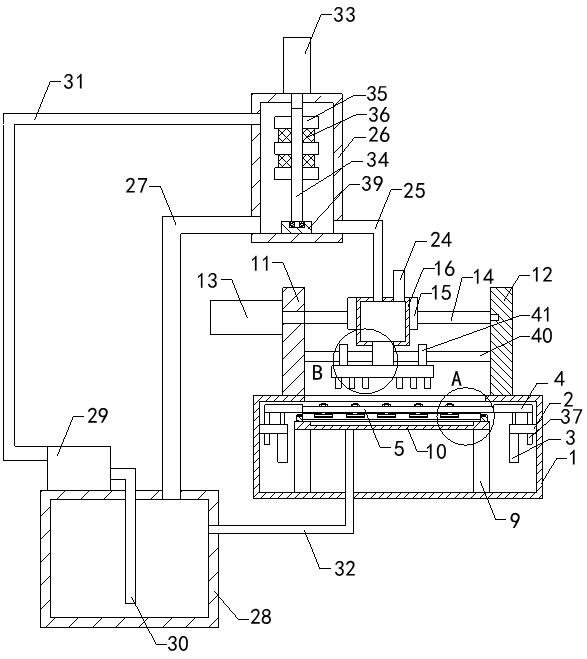

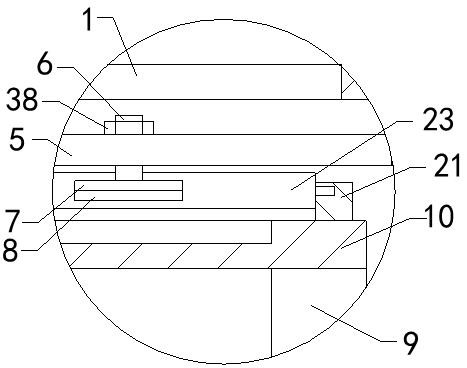

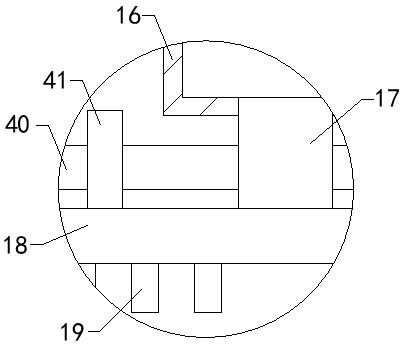

[0025] see Figure 1-5, a dyeing device for textile fabric processing, comprising a support box 1, the left end of the inner wall of the support box 1 and the right end of the inner wall are fixedly connected with cantilever plates 2, the bottom ends of each cantilever plate 2 are equipped with cylinders 3, the output of each cylinder 3 The shaft ends pass through the cantilever plate 2 from the bottom of the cantilever plate 2 and protrude from the upper side of the cantilever plate 2. The output shaft ends of each cylinder 3 are fixedly connected with a connecting plate 4, and the bottom ends of the connecting plate 4 are fixedly connected. There are sliding shafts 37, and the bottom ends of each sliding shaft 37 pass through the cantilever plate 2 from the top of the cantilever plate 2; through the cooperation of the sliding shaft 37 and the cantilever plate 2, the movement posture of the connecting plate 4 is limited, and the limit plate 41 is reduced. And the deformation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com