Multifunctional concrete leveling equipment

A concrete and multi-functional technology, applied in the direction of non-rotational vibration suppression, construction, building construction, etc., can solve the problems of unbalanced force, slow grinding, difficult to control, etc., to save time and personnel costs, increase use The effect of long life and high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

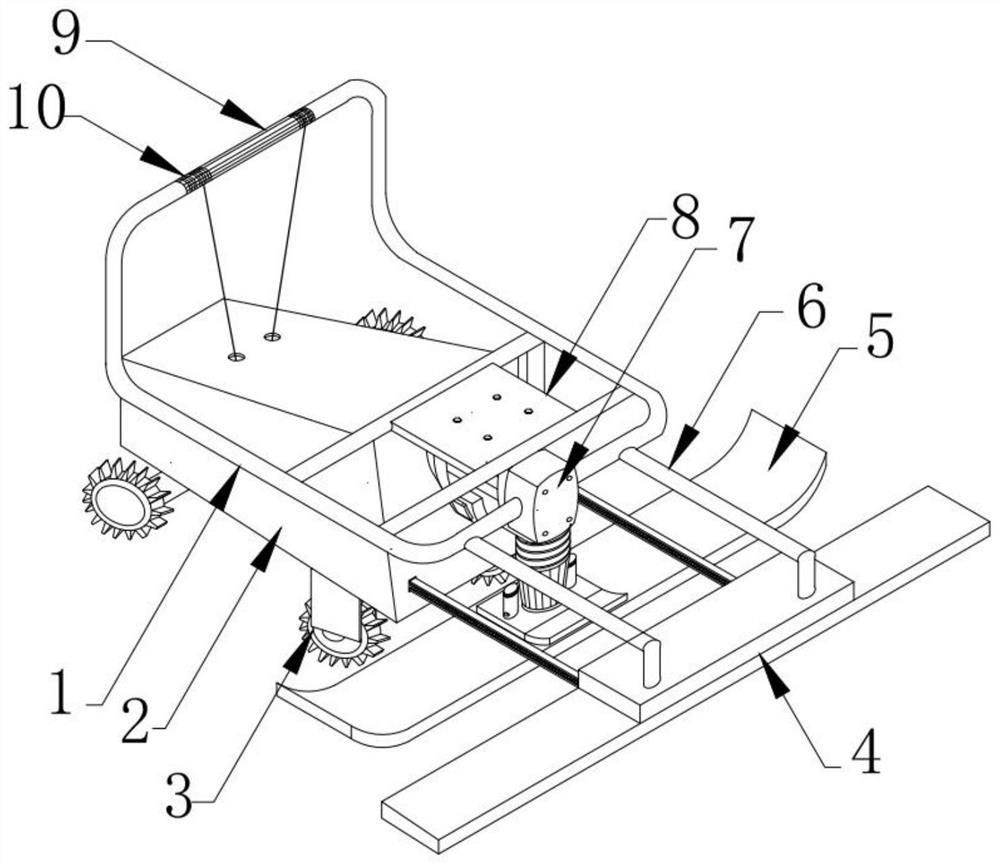

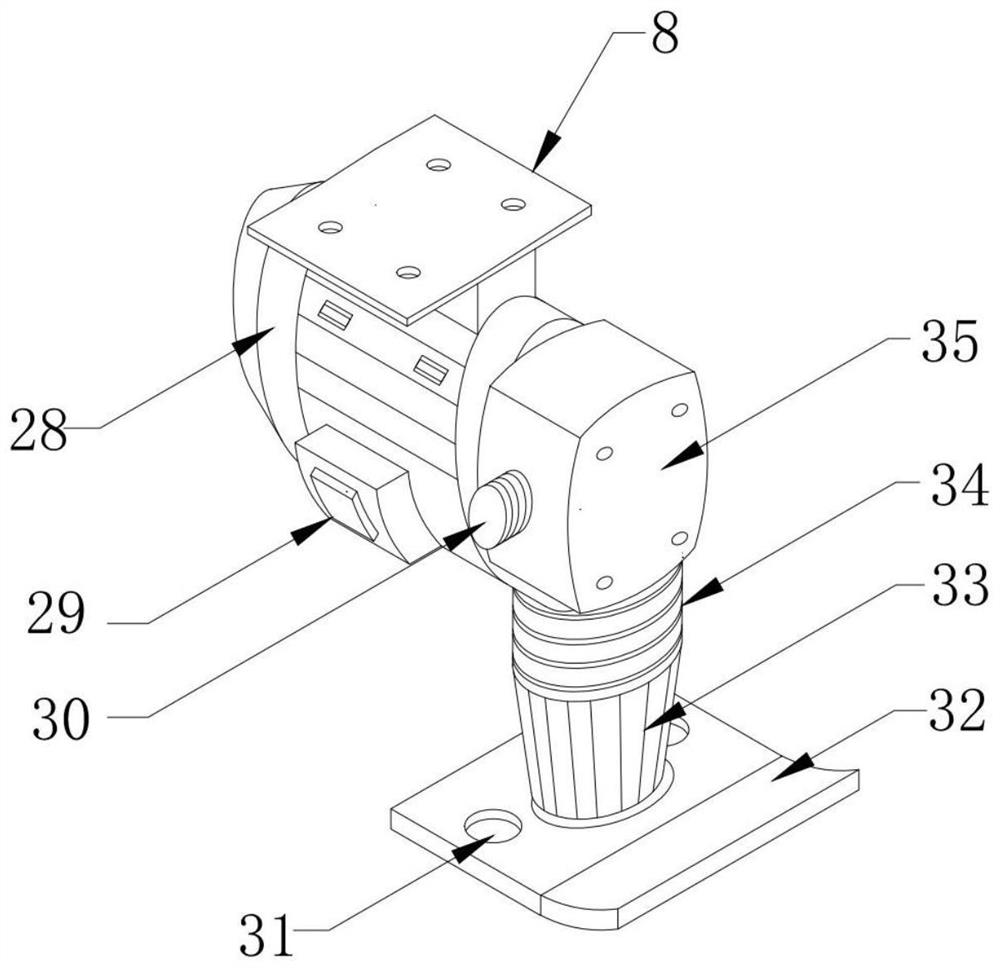

[0032] from Figure 1-9 It can be seen that the multifunctional concrete leveling equipment of this embodiment includes a frame 1, a cabinet 2 and an impact leveling machine 7, the cabinet 2 and the frame 1 are fixedly welded, and the upper part of the frame 1 is fixedly connected with a fixed plate 8, The upper part of the impact leveling machine 7 is fixedly connected with the fixed plate 8 through studs, and two connecting rods 6 are arranged symmetrically on the left and right at the front of the frame 1. Shock armrest9.

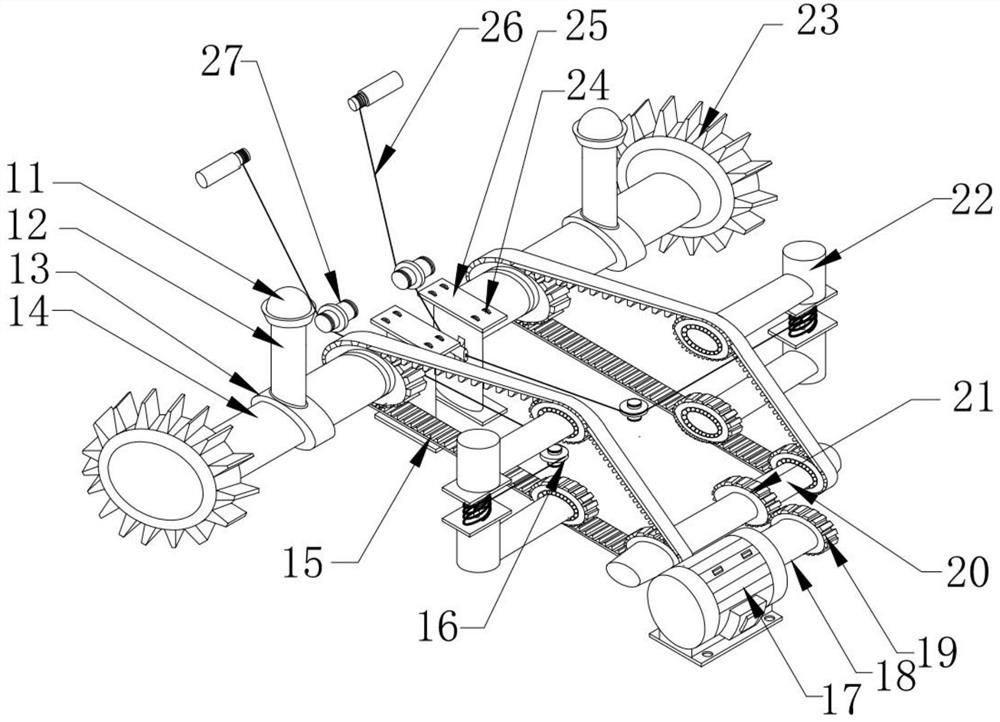

[0033] A drive motor 17 is fixedly installed inside the cabinet 2, an output shaft 18 is provided at the output end of the drive motor 17, and an output shaft gear 19 is fixedly connected to one end of the output shaft 18, and the left side of the output shaft gear 19 is provided with a first roller 20, and The middle part and both ends of a roller 20 are respectively provided with a first shaft gear 21, the first shaft gear 21 in the middle part of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap