Large throwing machine rotary table driving device using renewable energy

A renewable energy and driving device technology, applied in the field of hydraulic system energy saving, can solve the problems of energy waste, high cost, complicated driving device, etc., and achieve the effect of improving complex structure and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

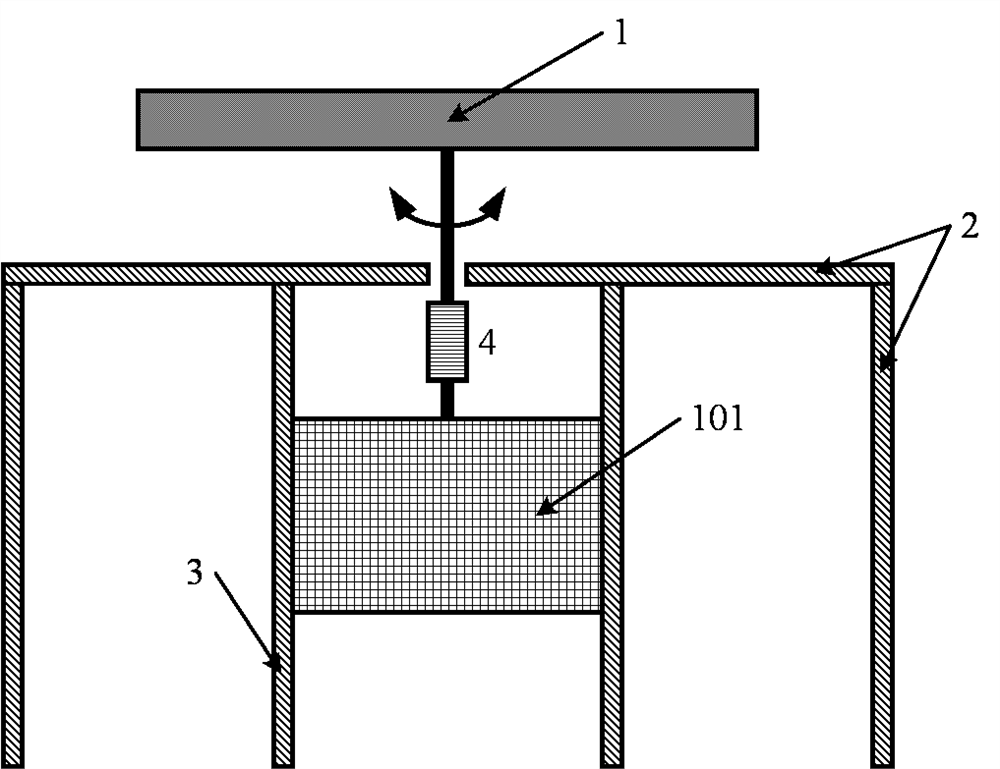

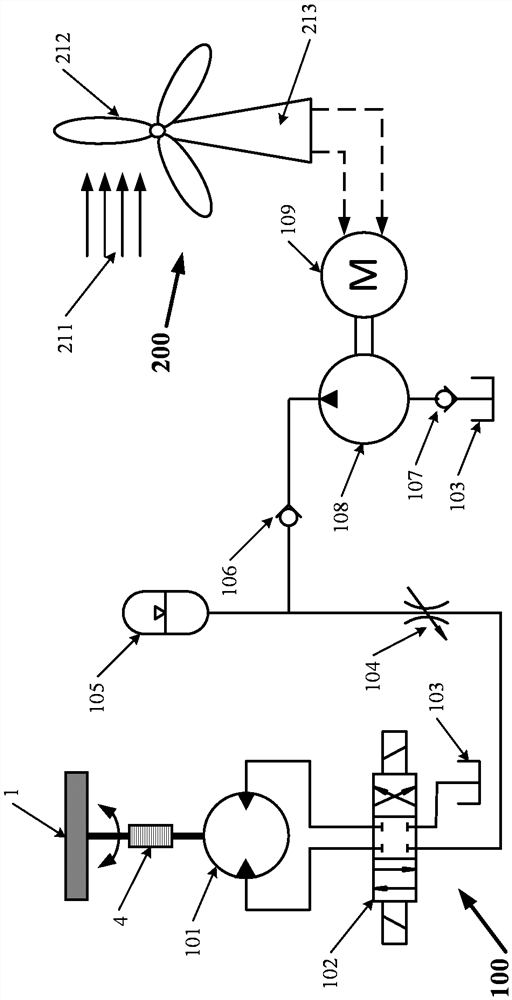

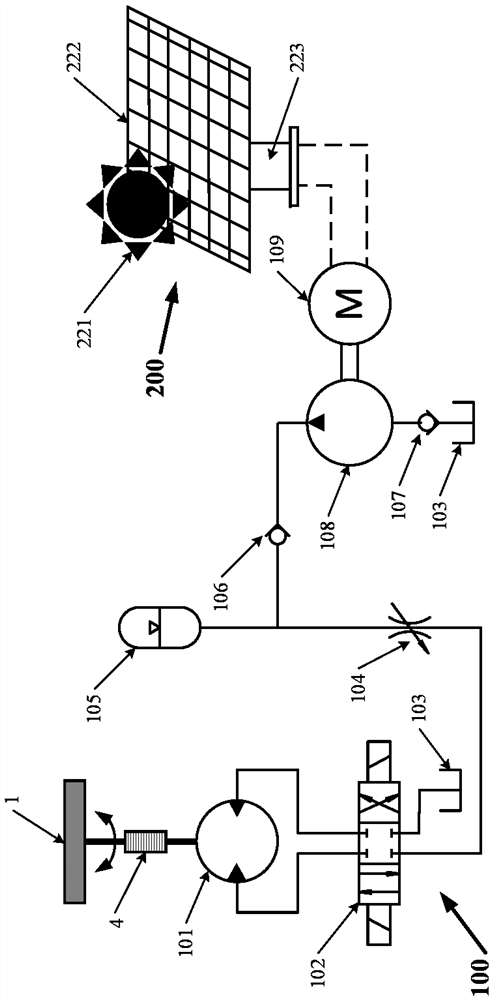

[0015] like figure 1 , figure 2 , image 3 As shown, a large slider aircraft drive device using renewable energy, including: turntable 1, housing 2, hydraulic motor support frame 3, coupling 4, hydraulic driving energy saving module 100, renewable energy module 200; The hydraulic driving energy-saving module 100 includes a bidirectional hydraulic motor 101, a triple four-way solenoid valve 102, a hydraulic oil tank 103, an adjustable throttle valve 104, a hydraulic accumulator 105, a first one-way valve 106, a second single-way valve 107, hydraulic pump 108, motor 109; the turntable 1 is disposed on the upper casing 2, the drive shaft of the turntable 1 is connected to the two-way hydraulic motor 101, the hydraulic motor support frame 3 is disposed at The outer casing 2 is connected to the outer casing 2 and is used to secure the bidirectional hydraulic motor 101; the two-way hydraulic motor 101 is connected to the A port and B port of the three four-way solenoid valve 102, and thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com