Internal cylinder body and rotary internal combustion engine

A technology for internal cylinders and internal combustion engines, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of mechanical inertia conversion loss, affecting air intake efficiency, and low mechanical efficiency, so as to improve efficiency and economy. Improve the effect of complex structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

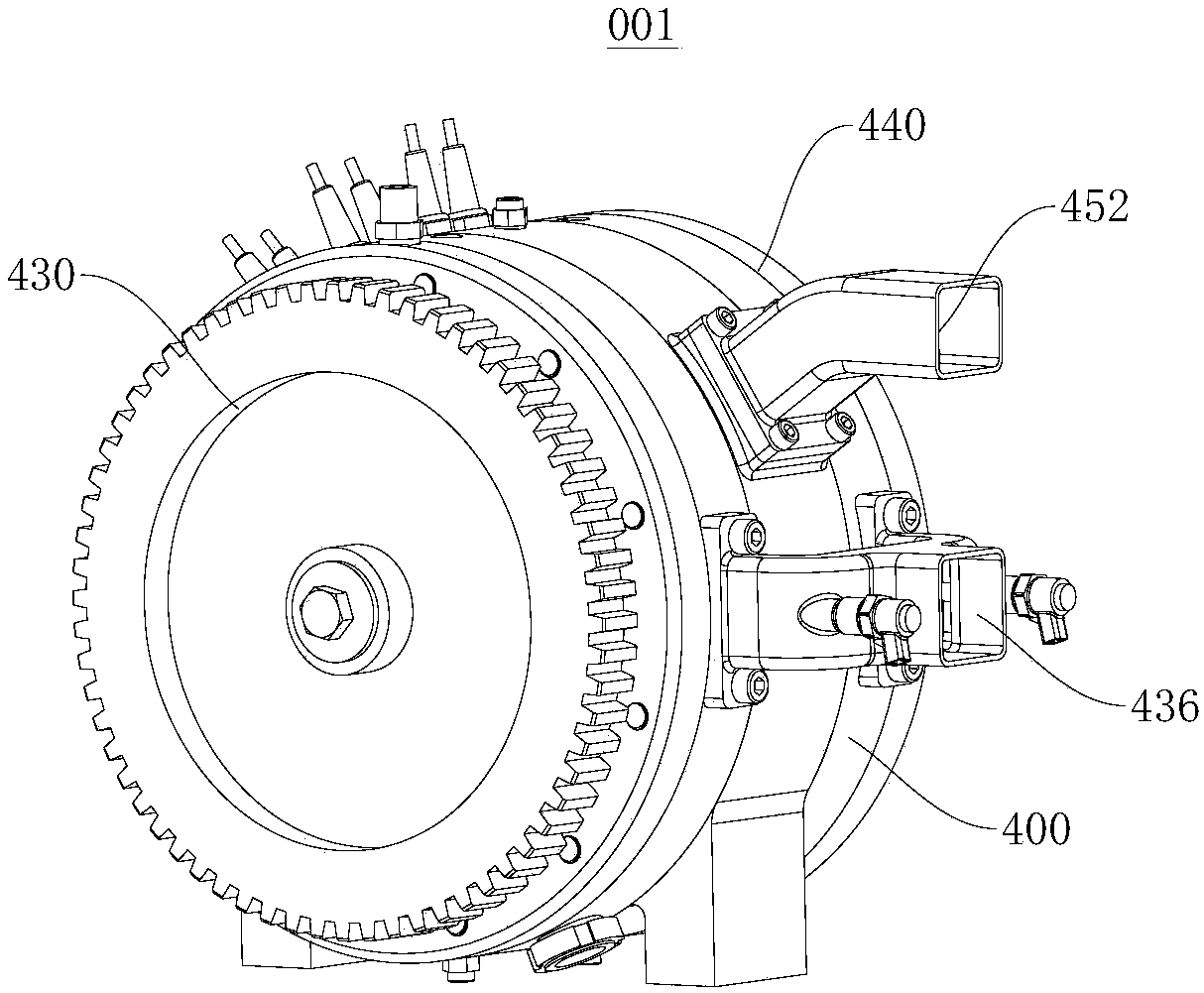

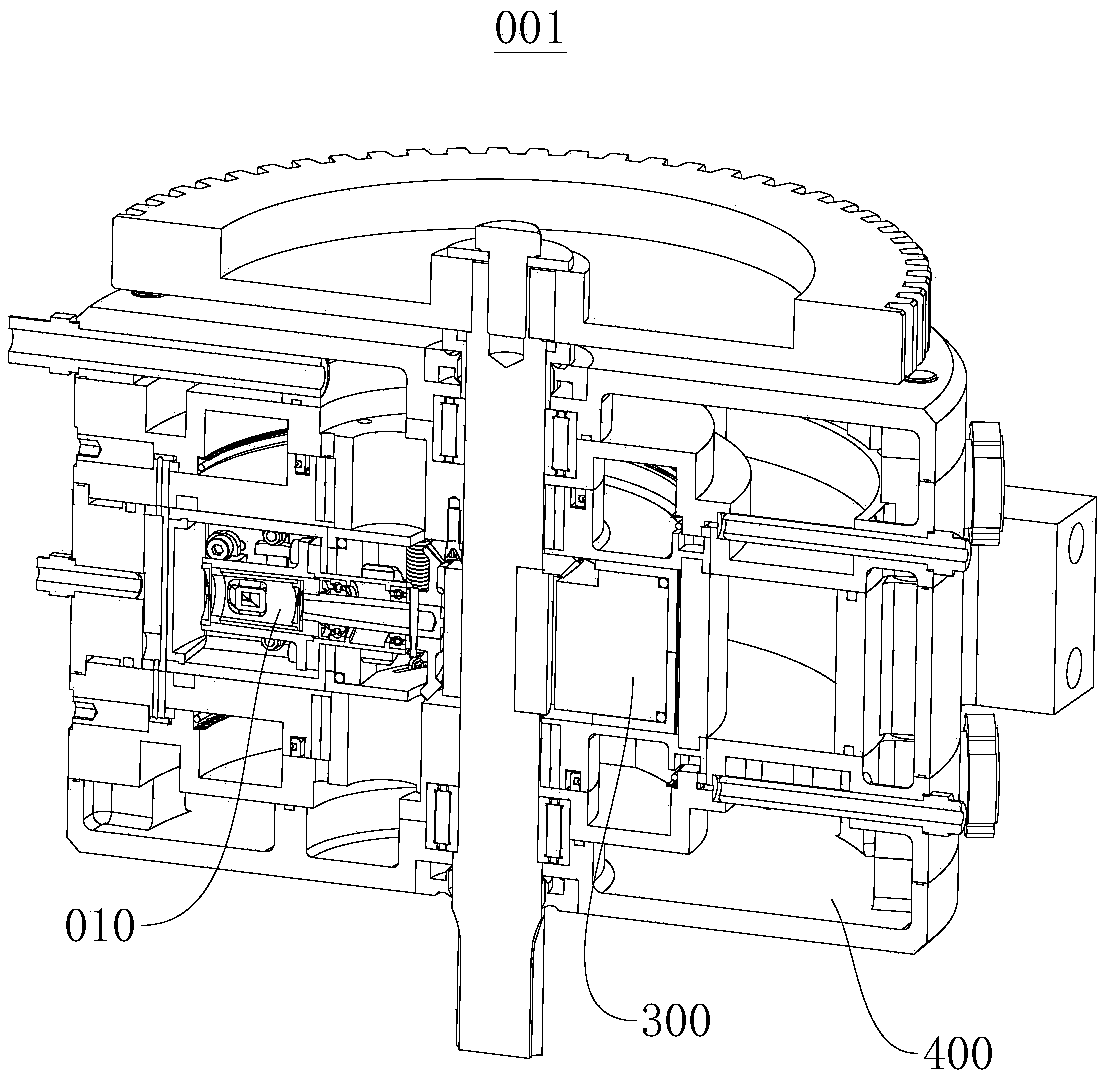

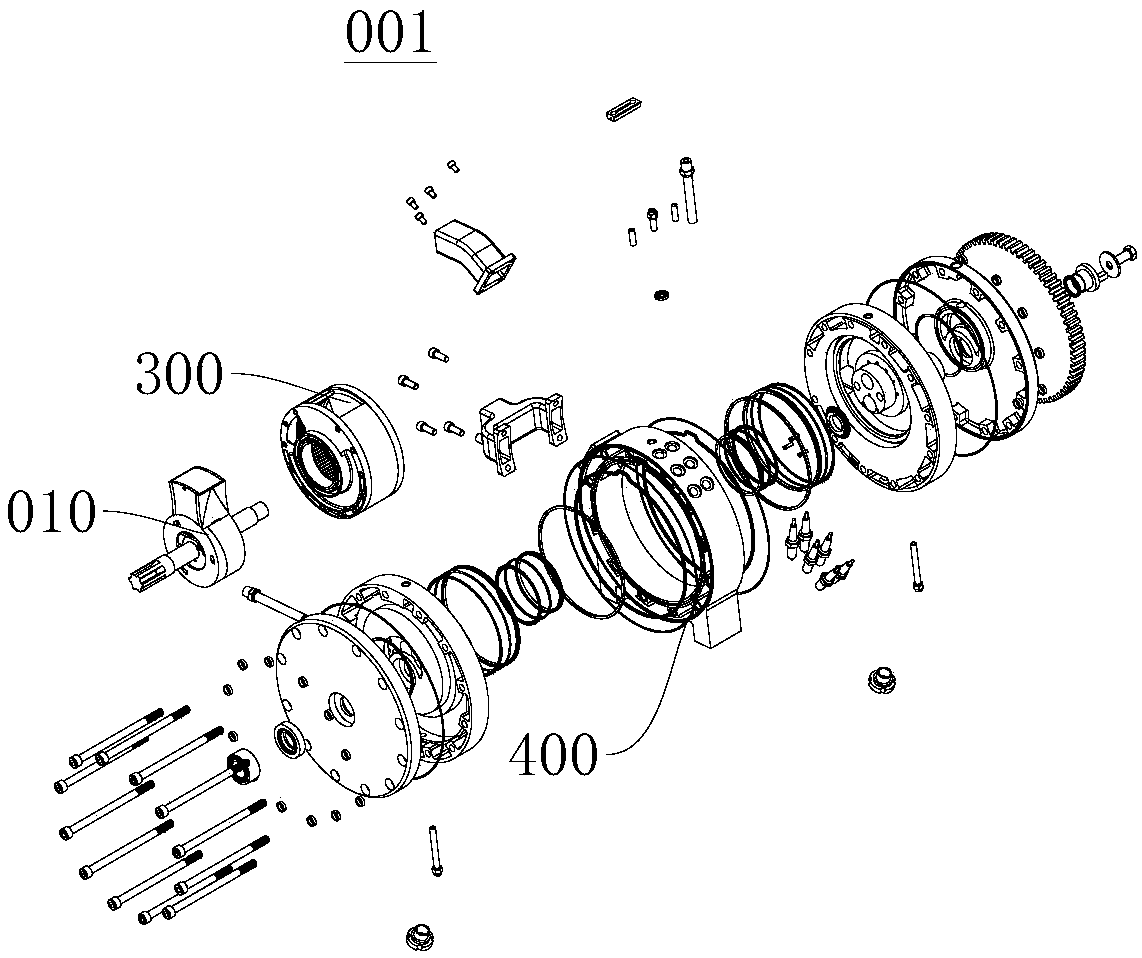

[0049] refer to Figure 1 to Figure 15 , the present invention provides a rotary internal combustion engine 001, comprising an outer cylinder 400, an inner cylinder 300 and a piston shaft assembly 010, an exhaust passage 452, an intake passage 434 and a spark plug 410 are arranged on the peripheral wall of the outer cylinder 400, The inner cylinder 300 is rotatably connected to the outer cylinder 400, the inner cylinder 300 rotates around its axis relative to the outer cylinder 400, and the axis of the inner cylinder 300 is staggered from the axis of the outer cylinder 400, The outer wall of the inner cylinder 300 is cut from the inner wall of the outer cylinder 400; the piston shaft assembly 010 includes a piston assembly 200 and a screw frame, the piston assembly 200 is installed on the screw frame, the screw frame is located in the inner cylinder 300, and the screw The frame is rotatably connected with the outer cylinder body 400, the spiral frame rotates relative to the ou...

Embodiment 2

[0073] Please refer to the drawings in Embodiment 1, the present invention also provides a rotary internal combustion engine 001, comprising an outer cylinder 400, an inner cylinder 300 and a piston shaft assembly 010, and an exhaust passage is arranged on the peripheral wall of the outer cylinder 400 , air inlet and spark plug, the inner cylinder 300 is connected to the outer cylinder 400 in rotation, the inner cylinder 300 rotates around its axis relative to the outer cylinder 400, and the axis of the inner cylinder 300 is connected to the outer cylinder 400 The axis line of the cylinder is staggered, and the outer wall of the inner cylinder 300 is cut to the inner wall of the outer cylinder 400; the piston shaft assembly 010 includes a screw frame and more than two piston assemblies 200, and more than two piston assemblies 200 They are respectively installed on the spiral frame, and more than two piston assemblies 200 are arranged at equal intervals around the axis line of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com