Spiral electric heating pipe efficient gas heater

A gas heater and electric heating tube technology, which is applied to air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem that the improvement of heating efficiency is not obvious, the improvement of gas heating effect is not obvious, and the electric heater works. The problem of low efficiency is to prevent heat dissipation, simple structure and high total power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

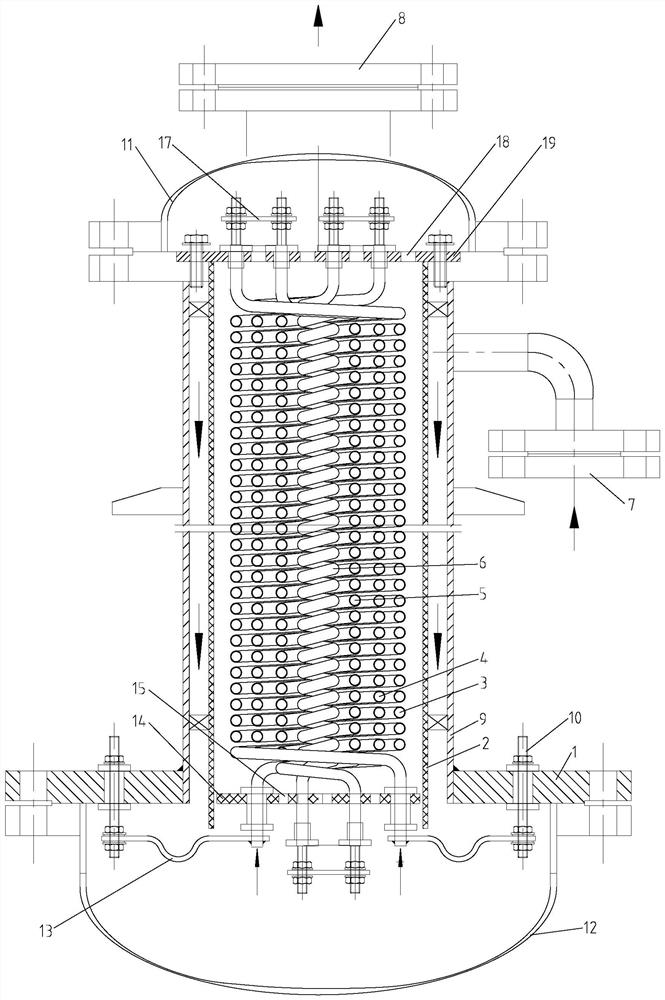

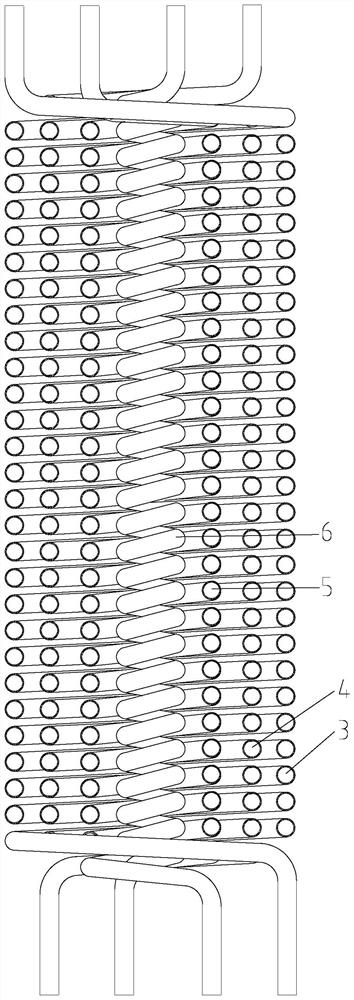

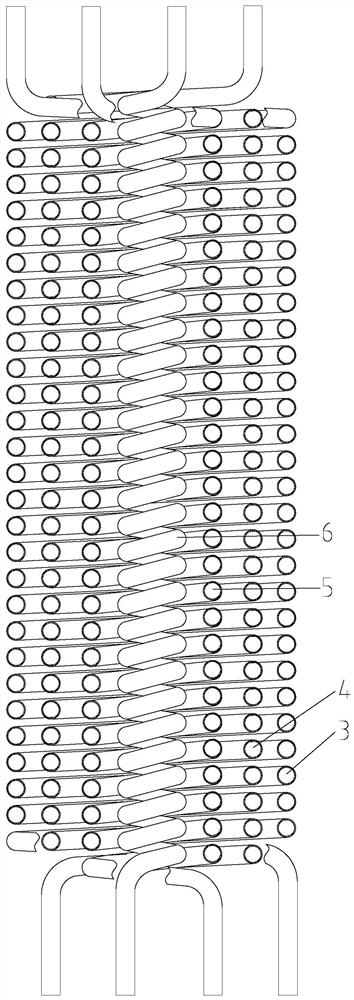

[0018] As shown in the figure, a spiral-shaped electric heating tube high-efficiency gas heater, the main installation and connection support structure is the outer casing 1, and the outer casing 1 can be fixedly supported and installed by the flange plate and the equipment; The shell 2 and the multilayer tubular resistance element, the multilayer tubular resistance element is fixedly supported and installed by the inner shell 2, and the multilayer tubular resistance element is a spiral coil resistance element formed by spirally rising tubular heating elements; the multilayer tubular resistance The upper and lower ends of the element are sequentially connected end to end in series, the first layer of tubular resistance element located in the outermost layer and the lower end of the second layer of resistance element adjacent to the first layer of tubular resistance element are respectively connected to the electrode 10, the multilayer tubular resistance element The electrode 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com