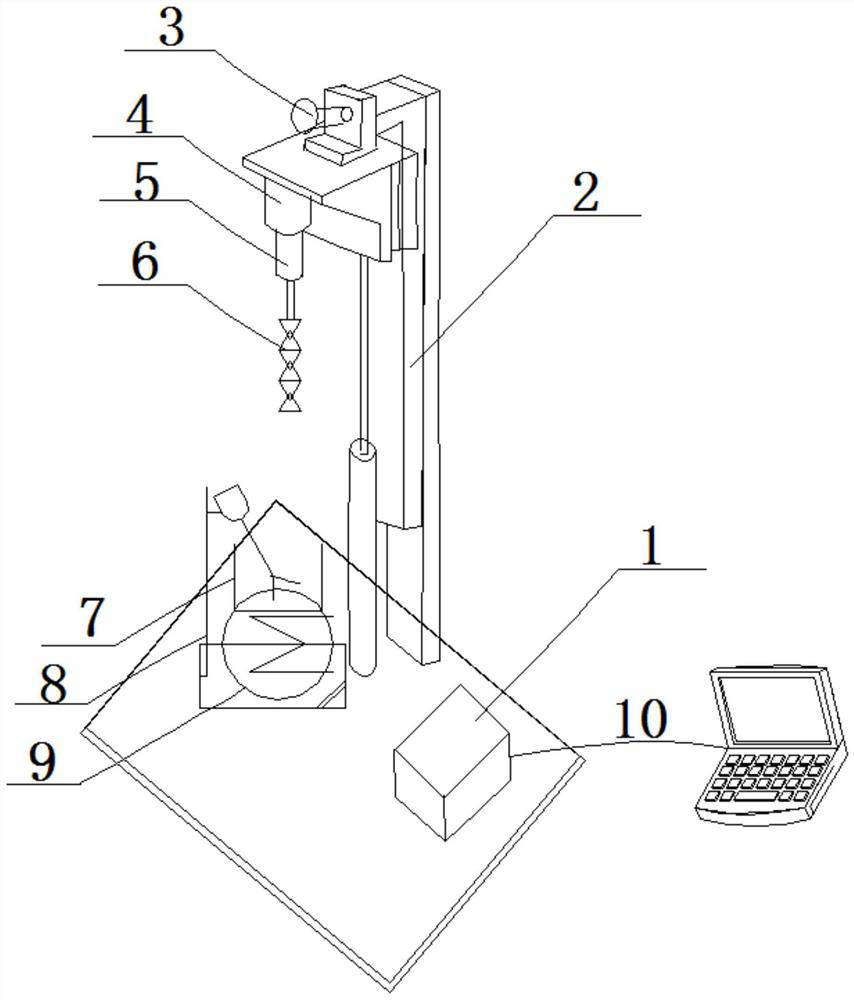

Starch viscosity testing system and testing method

A test system and test method technology, applied in the fields of starch, food and soaking materials, can solve the problems affecting the accuracy of viscosity test results, unsuitable for long-term heating, difficult viscosity test, etc., to achieve convenient measurement, accurate and comprehensive measurement data, The effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] S1. Place the measuring cup in an air bath heating and stirring device, add a certain amount of deionized water at room temperature, and then slowly add common wheat starch into the measuring cup according to the weight ratio of deionized water and starch 5:1. Dissolve while stirring, and obtain a mixed solution after complete dissolution;

[0028] S2, after the mixed solution in step S1 is heated to 50°C, every time the temperature rises by 5°C, cook for 10min in a constant temperature heating and stirring device, and the heating temperature is 130°C to obtain a starch solution;

[0029] S3, use the viscosity measuring device to test the viscosity of the starch solution while maintaining the heating, transmit the test data to the data recording and display device, and record and display the test temperature and viscosity;

[0030] S4. The temperature and viscosity data measured multiple times are automatically drawn by the system into a viscosity versus temperature cur...

Embodiment 2

[0033] S1, place the measuring cup in a water bath constant temperature heating magnetic stirring device, add a predetermined amount of deionized water at room temperature, then press the weight ratio of deionized water and starch 30:1, slowly add a certain amount of rice high amylose starch to measure In the cup, dissolve while stirring, and obtain a mixed solution after complete dissolution;

[0034] S2, start from 50 ℃, every 10 ℃, cook in the constant temperature heating and stirring device for 120min,

[0035] S3. Use a viscosity measuring device to test the viscosity of the liquid while heating, and transmit the test data to a data recording and display device to record and display the temperature and viscosity of this test.

[0036] S4. Record the data points of multiple measurements and the corresponding viscosity, and the system will automatically display the viscosity versus temperature curve.

[0037] The starch viscosity testing system and its testing method obtai...

Embodiment 3

[0039] A starch viscosity testing system and method for testing the same, comprising the following features and steps:

[0040] S1. Place the measuring cup in a sand bath constant temperature heating mechanical stirring device, add deionized water that is 10 times its own weight of potato low amylose at room temperature, and then slowly add a certain amount of potato low amylose into the measuring cup, Dissolve while stirring, and obtain a mixed solution after complete dissolution;

[0041]S2, the mixture is cooked at 50°C for 60min in a constant temperature heating and stirring device at intervals of 10°C,

[0042] S3. Use a viscosity measuring device to test the viscosity of the liquid, and transmit the test data to a data recording and display device to record and display the temperature and viscosity of this test. After the measurement, pour out the starch solution, wash the measuring cup, and rinse with deionized water.

[0043] S4, place the measuring cup in an oil bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com