A kind of thin film piezoelectric acoustic wave filter and its manufacturing method

A piezoelectric sound wave and manufacturing method technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of the material of the sealing layer entering the cavity and low reliability, and achieve good control, increased flexibility, and balanced support strength required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

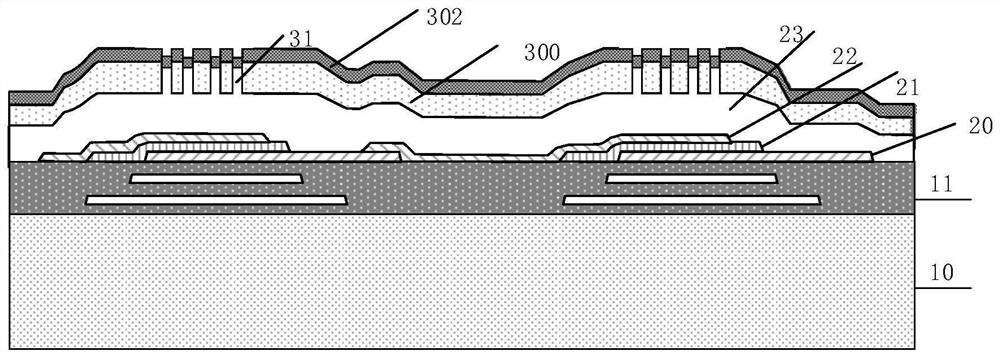

[0036] An embodiment of the present invention provides a thin-film piezoelectric acoustic wave filter, figure 1It is a schematic structural diagram of a thin-film piezoelectric acoustic wave filter according to an embodiment of the present invention, wherein only two acoustic wave resonator units are shown in the figure, and the specific number of acoustic wave resonator units in each filter and the electrical connection between them are shown. The mode is specifically set according to the requirements of the filter itself.

[0037] Please refer to figure 1 , the thin-film piezoelectric acoustic wave filter includes:

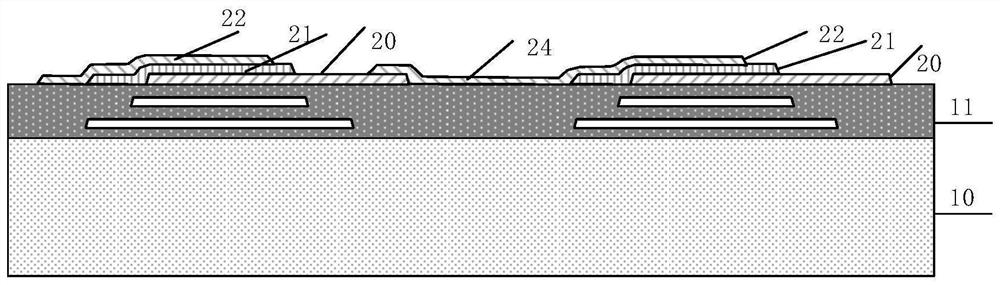

[0038] a first substrate; a plurality of acoustic wave resonator units placed on the first substrate; the acoustic wave resonator unit is the smallest resonance unit, and each acoustic wave resonator unit includes a piezoelectric induction sheet 21 for resonating the The piezoelectric induction sheet body 21 applies a voltage to the first electrode and the sec...

Embodiment 2

[0053] This embodiment provides a method for manufacturing a thin-film piezoelectric acoustic wave filter, the method comprising:

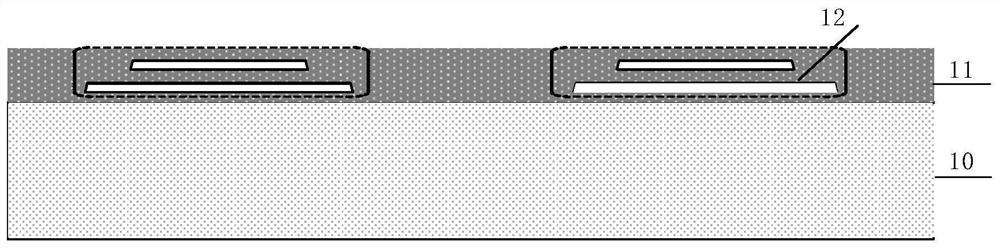

[0054] S01: provide a first substrate;

[0055] S02: forming a plurality of acoustic wave resonator units on the first substrate, each acoustic wave resonator unit including a piezoelectric induction sheet body and first electrodes opposite to each other for applying a voltage to the piezoelectric induction sheet body , the second electrode;

[0056] S03: forming a sacrificial layer on at least two of the acoustic wave resonator units and the spaced area between the acoustic wave resonator units;

[0057] S04: forming a cap layer body, covering the sacrificial layer, forming a release hole with a set aperture on the cap layer body, and removing the sacrificial layer through the release hole to form a first cavity;

[0058]S05: Form a capping layer on the capping layer body, so that the capping layer is partially embedded in a part of the release...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com