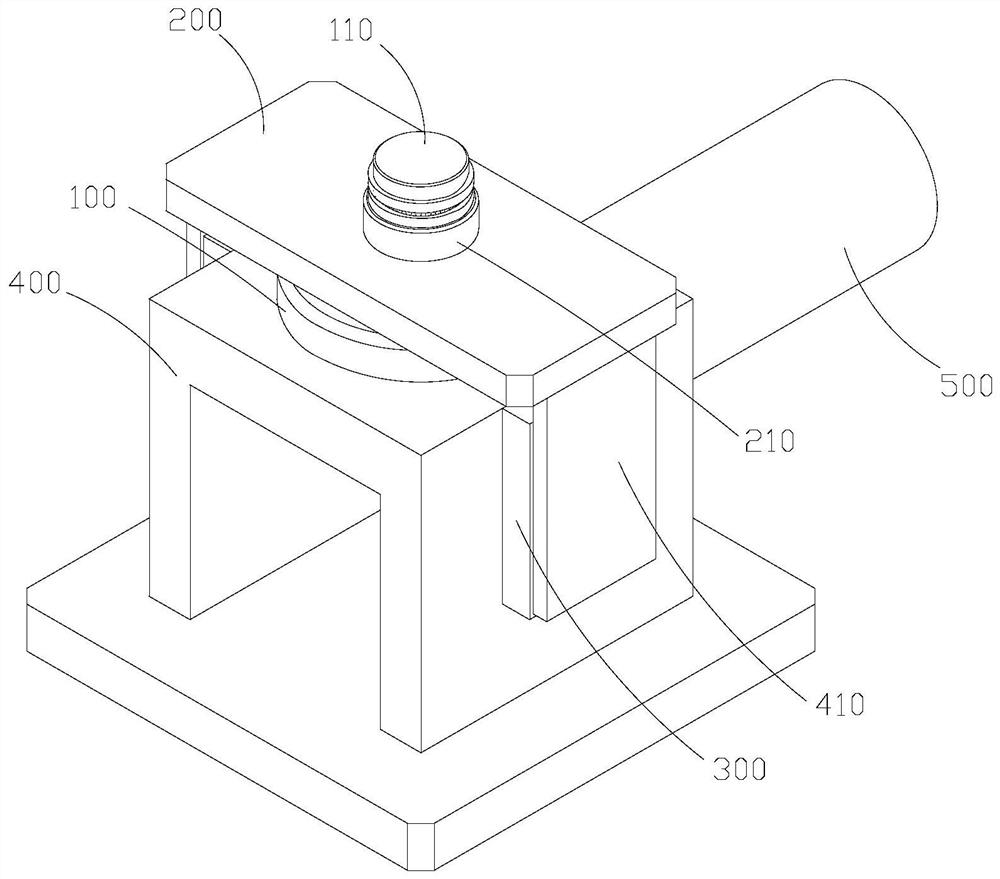

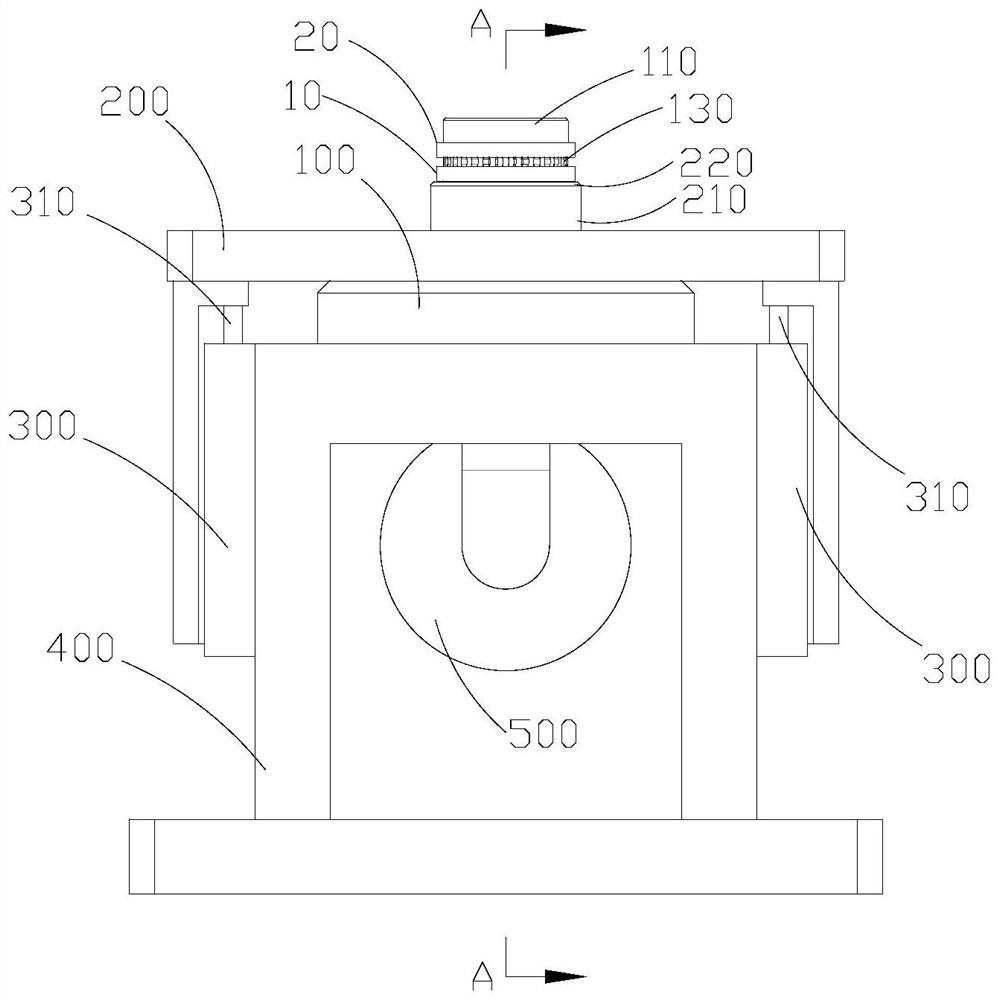

Loudspeaker, voice coil, voice coil manufacturing method and coil heating device

The technology of a heating device and a manufacturing method, which is applied in the field of loudspeakers, can solve the problem of low heat utilization rate, and achieve the effects of reducing manufacturing cost, reducing heat loss, and simplifying heating structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

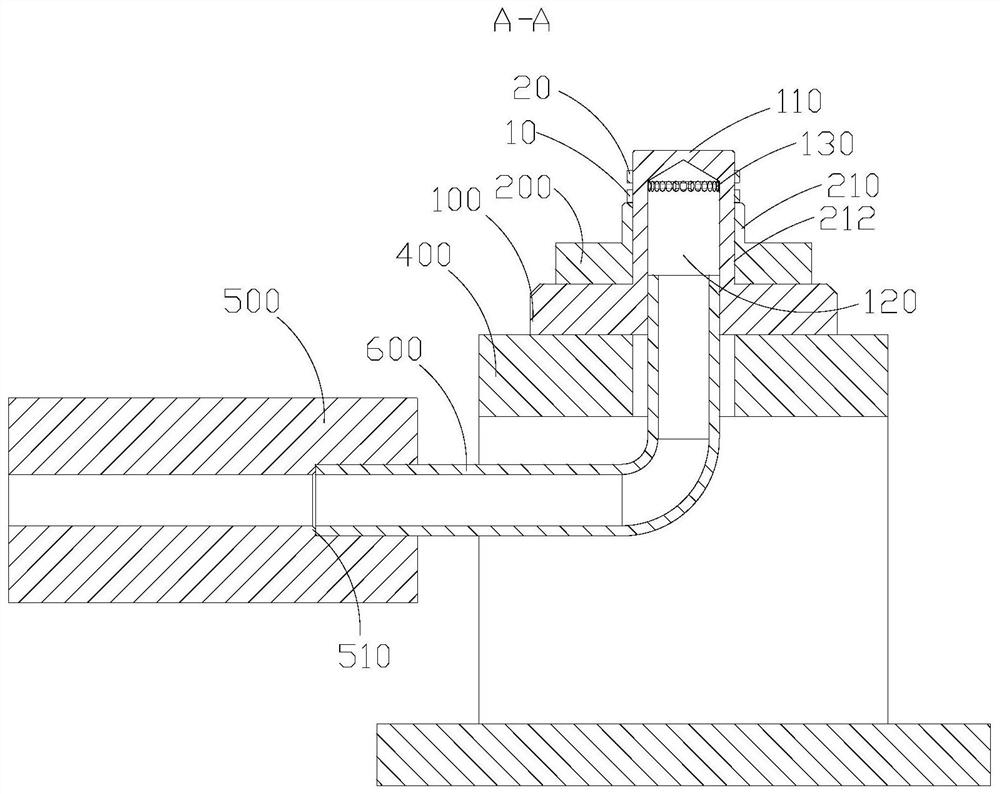

[0055] In the second embodiment, a voice coil manufacturing method is also provided, which utilizes the coil heating device in any of the above embodiments, including the following steps:

[0056] Inserting the first coil 10 into the heating column 110, and then inserting the second coil 20 into the preset position of the heating column 110;

[0057] Pass the heating gas into the heating column 110 through the flow channel 120;

[0058] reaching the preset time or preset temperature, so that the first coil 10 and the second coil 20 are in close contact;

[0059] The first coil 10 and the second coil 20 are bonded and fixed to form a voice coil.

[0060] When the voice coil manufacturing method above is used, the hot air directly acts on the heating column 110 through the flow channel 120, and the heat energy can be fully utilized to heat the heating column 110, reducing heat loss and improving heat utilization; 110 in the flow channel 120, so that the heating column 110 can ...

Embodiment 3

[0064] In the third embodiment, a voice coil is also provided, which is obtained by using the voice coil manufacturing method in any of the above embodiments. The voice coil adopts the above method for manufacturing the voice coil, which can reduce energy loss in the manufacturing process and is beneficial to reduce the manufacturing cost.

Embodiment 4

[0065] In Embodiment 4, a loudspeaker is also provided, which adopts the above-mentioned voice coil. The loudspeaker adopts the above-mentioned voice coil, which can reduce the production cost and help to improve the market competitiveness.

[0066] It should be noted that the coil is obtained by winding a metal wire coated with glue, so the bonding between the coils can be fixed without applying glue, and can be fixed into a voice coil by direct heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com