3D printing preparation method for implant abutment top localizer

A 3D printing and locator technology, applied in the field of medical devices, can solve the problems of easy errors, low production efficiency, dependence on experience and proficiency, and achieve high accuracy, high efficiency and precision, and meet safety and stability required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

[0028] A kind of method utilizing 3D printing to prepare Zhuanggen locator, its steps are as follows:

[0029] 1) Obtain three-dimensional data of the patient's oral cavity: use a 3D scanner to perform three-dimensional scanning on the structure and shape of the patient's oral cavity to obtain three-dimensional data on the surface of the oral cavity structure. Preferably, the 3D scanner is a photographic 3D scanner.

[0030] 2) Establish a three-dimensional oral model in the computer: import the three-dimensional data into the 3SHAPE design software, and use the obtained three-dimensional data to establish the patient's oral structure model in 3SHAPE.

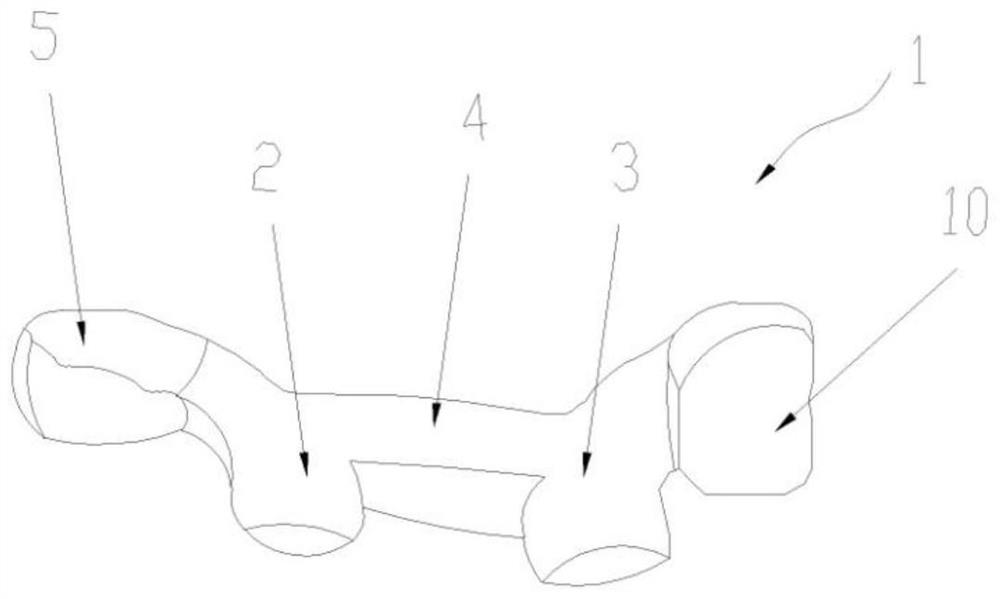

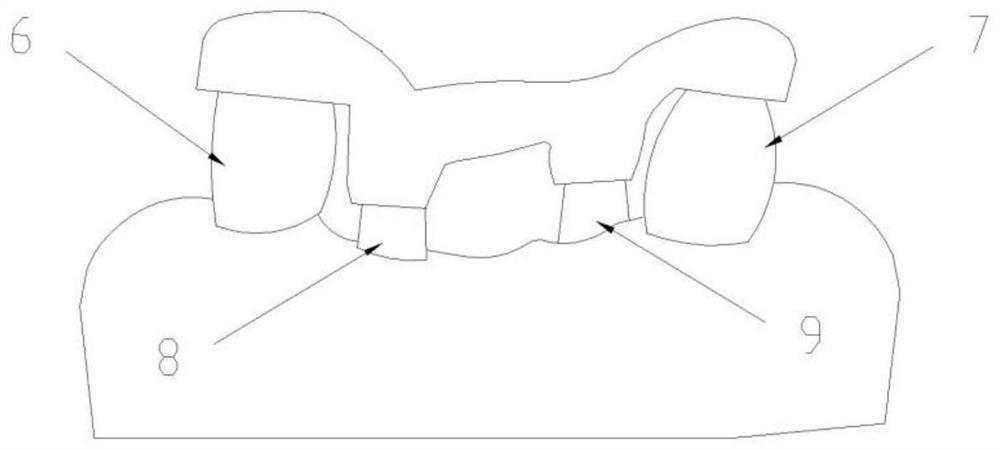

[0031] 3) Relevant oral structure area was intercepted: the relevant oral structure near the position of the patient's desired implant tooth was in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com