Machine for changing garden wastes into fertilizer

A garden waste and feeder technology, which is applied in the treatment of bio-organic parts, organic fertilizers, grains, etc., can solve the problems of garden waste consuming a lot of manpower and material resources, unsuitable for modern production and life, and physical discomfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

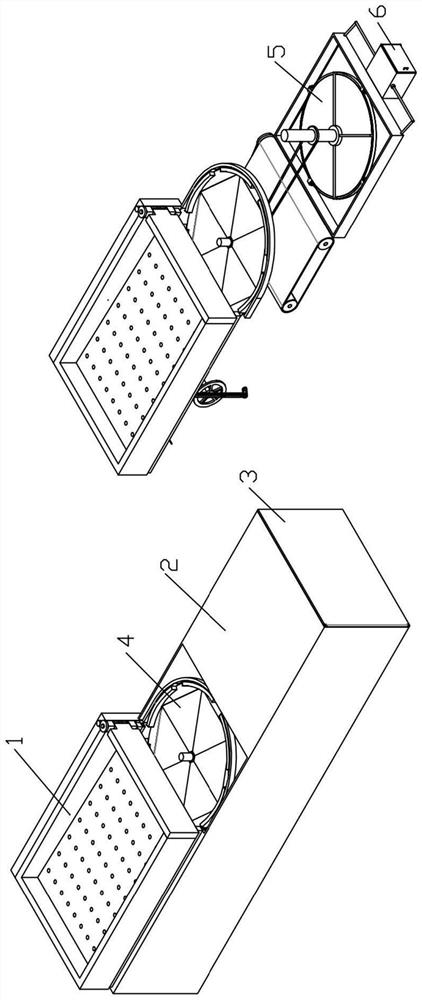

[0030] Combine below Figure 1-11 In order to solve the above-mentioned technical problems, the present invention relates to the technical field of garden machinery, more specifically, a garden waste chemical machine, comprising a screening device 1, a housing 2, a retrieving door 3, a centrifugal device 4, a crushing device 5 and Fermentation box 6; it is characterized in that: the sieving device 1 is movably connected with the housing 2, the housing 2 is hinged with the retrieving door 3, the housing 2 is provided with a centrifugal device 4, and the centrifugal device 4 A crushing device 5 is provided at the corresponding position of the lower end of the container, and the crushing device 5 is connected with the fermentation box 6; the garden waste is poured into the sieving device 1, and the sieving device 1 screens out sand and stone particles in the waste , then the unremovable sand and stone particles are removed by centrifugal force through the centrifugal device 4, an...

specific Embodiment approach 2

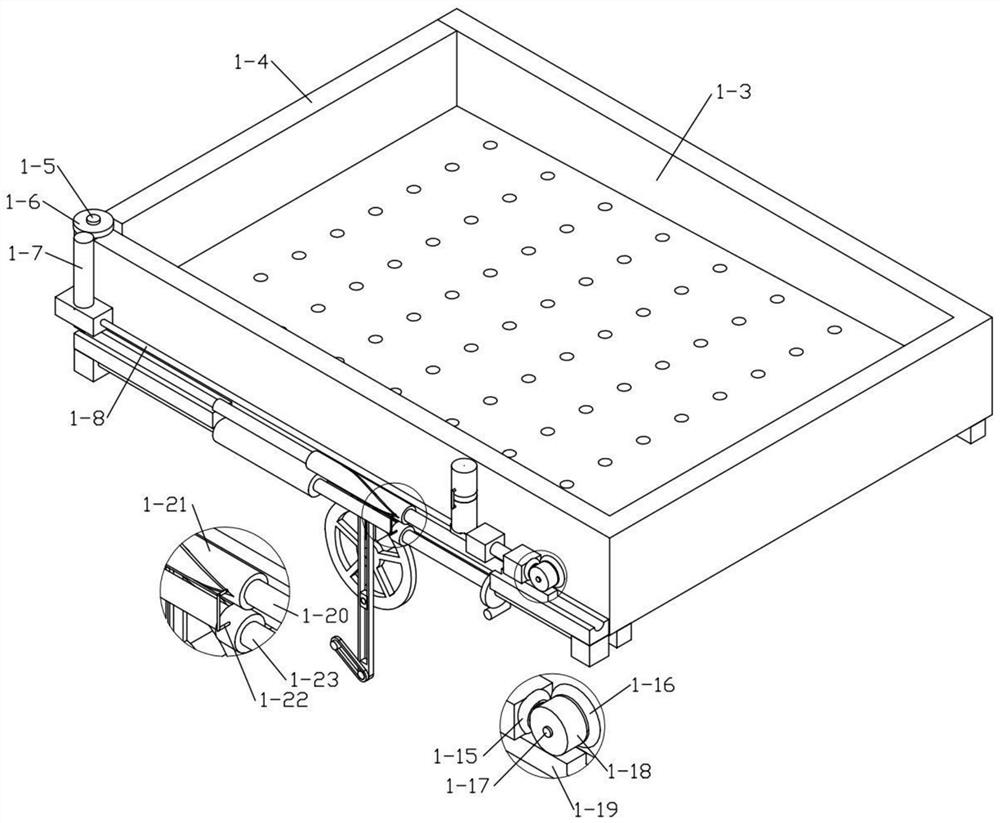

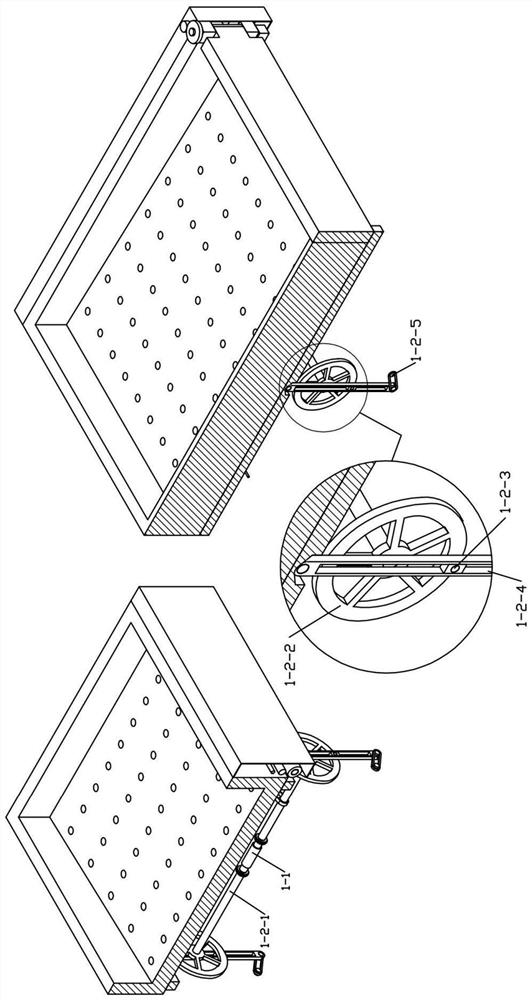

[0032] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain the first embodiment, the sieving device 1 includes a sieving motor 1-1, a transmission device 1-2, a sieve body 1-3, a discharge door 1-4, a hinge shaft 1-5, the first discharge turbine 1-6, the first discharge worm 1-7, the first discharge screw 1-8, the first screw nut 1-9, the first discharge helical gear 1-10 , the second discharge helical gear 1-11, the first discharge shaft 1-12, the second discharge turbine 1-13, the second discharge shaft 1-14, the third discharge helical gear 1-15, the fourth Discharge helical gear 1-16, third discharge shaft 1-17, discharge transmission gear 1-18, discharge transmission rack 1-19, third discharge worm 1-20, reversing roller 1-21, Reversing lever 1-22, fourth discharge shaft 1-23, third discharge worm gear 1-24, fourth discharge worm 1-25, fifth discharge shaft 1-26, first discharge pulley 1 -27. The second discharge pulley 1-28 and the...

specific Embodiment approach 3

[0037] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain Embodiment 1, the centrifugal device 4 includes a transmission shaft 4-1, a first transmission pulley 4-2, a first transmission belt 4-3, a second transmission pulley 4-4, The second transmission belt 4-5, the transmission disc 4-6, the first transmission rod 4-7, the second transmission rod 4-8, the fixed rod 4-9, the fixed rack 4-10, the fixed gear 4-11, the fixed Shaft 4-12, first centrifugal pulley 4-13, second centrifugal pulley 4-14, centrifugal belt 4-15, centrifugal shaft 4-16, first centrifugal helical gear 4-17, second centrifugal helical gear 4 -18, centrifugal screw 4-19, centrifugal screw nut 4-20, first articulated rod 4-21, second articulated rod 4-22, third articulated rod 4-23, centrifugal frame 4-24, anti-out material semicircular frame 4-25 and hinged plate 4-26; two groups of transmission shafts 4-1 are arranged in the housing 2, and the first transmission pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com