A new type of vibration-absorbing mooring line and its general selection method

A mooring line and a new type of technology, applied in ships and other directions, can solve problems such as affecting the normal use function and life of the instrument, poor vibration damping performance, aggravating vibration, etc., to solve the problem of excessive vibration interference, ensure work stability and Reliability, the effect of improving vibration damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

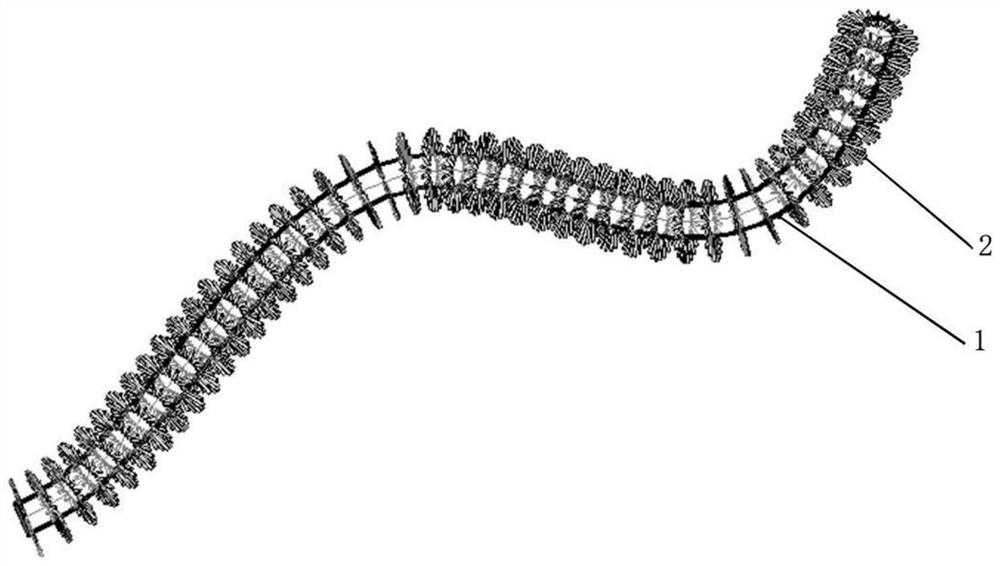

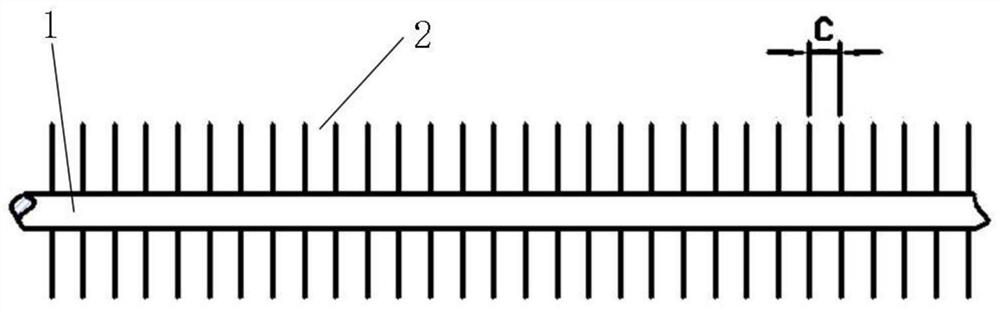

[0037] Embodiment 1 This embodiment provides a new type of vibration-damping mooring line, the structure of which is as follows: figure 1 and 2 As shown, it consists of a cable 1 and a vibration-damping brush 2 arranged on the cable 1 . Wherein, the vibration damping brush 2 is an annular annular brush, and the annular brush is fixed with the cable 1 by means of bundling, compression molding or sticking.

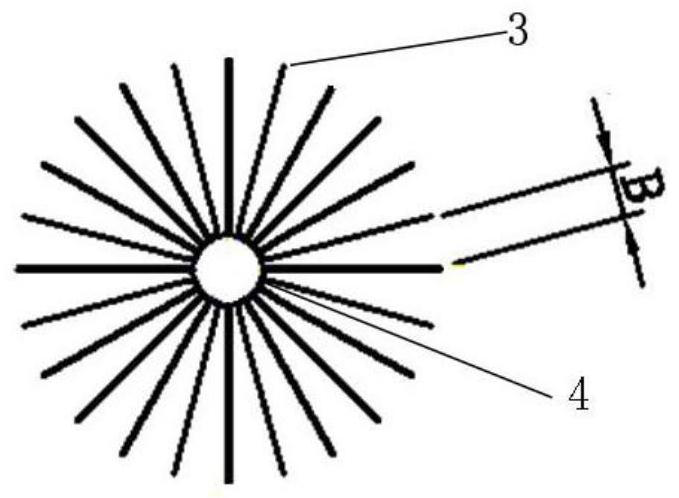

[0038] The structure of the anti-vibration brush 2 is as follows image 3 As shown, it consists of a base 4 and bristles 3 . The bristles 3 are hard bristles with a length of 30-60mm, and are fixed on the base 4 at equal intervals.

Embodiment 2

[0039] Embodiment 2 For the new vibration-damping mooring line of this embodiment, the vibration-damping brush can also be a ribbon brush, such as Figure 4 As shown, the ribbon-shaped brushes are helically wound around the cable 1 at equal intervals, and are fixed together with the cable 1 by means of bundling, compression molding or gluing.

[0040] Compared with the existing mooring line, the new vibration-damping mooring line of this embodiment has significant vibration-damping performance, which can significantly reduce the vibration of the line in the axial and radial directions, and reduce the impact on underwater instruments and equipment. .

Embodiment 3

[0041] Example 3 This implementation provides a general selection method for a new type of vibration-damping mooring line, taking the test of different bristle lengths of annular brushes as an example, specifically including:

[0042] (1) In a water flow environment with the same flow velocity (2 knots flow velocity), keep the arrangement distance C of the brush 2 on the cable 1 the same (the specific value of the arrangement distance is 30mm), and the arrangement distance B of the bristles 3 on the brush 2 ( The specific value of 15.7mm) is the same, the bristles 3 on the brush 2 are made of hard material, and the same cable length (the specific length value is 15 meters) is used to test the axial acceleration signals of the 30mm and 60mm lengths of the bristles 3. Comparison in the frequency domain.

[0043] The results are shown in Figures 5(a) and 6(a), in the time domain, the average amplitudes of acceleration in the axial and radial directions of the bristle cable with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com