Double-sided circulation basket used for placing motors

A technology for motor rotors and turnover baskets, which is applied to machine containers, containers for preventing mechanical damage, and assembly machines, etc. It can solve the problems of high weight of turnover baskets, increased processing costs of turnover baskets, lack of anti-collision measures, and inability to effectively prevent motor rotors from sliding and other issues, to achieve the effect of reducing processing cost, reducing weight, and preventing sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

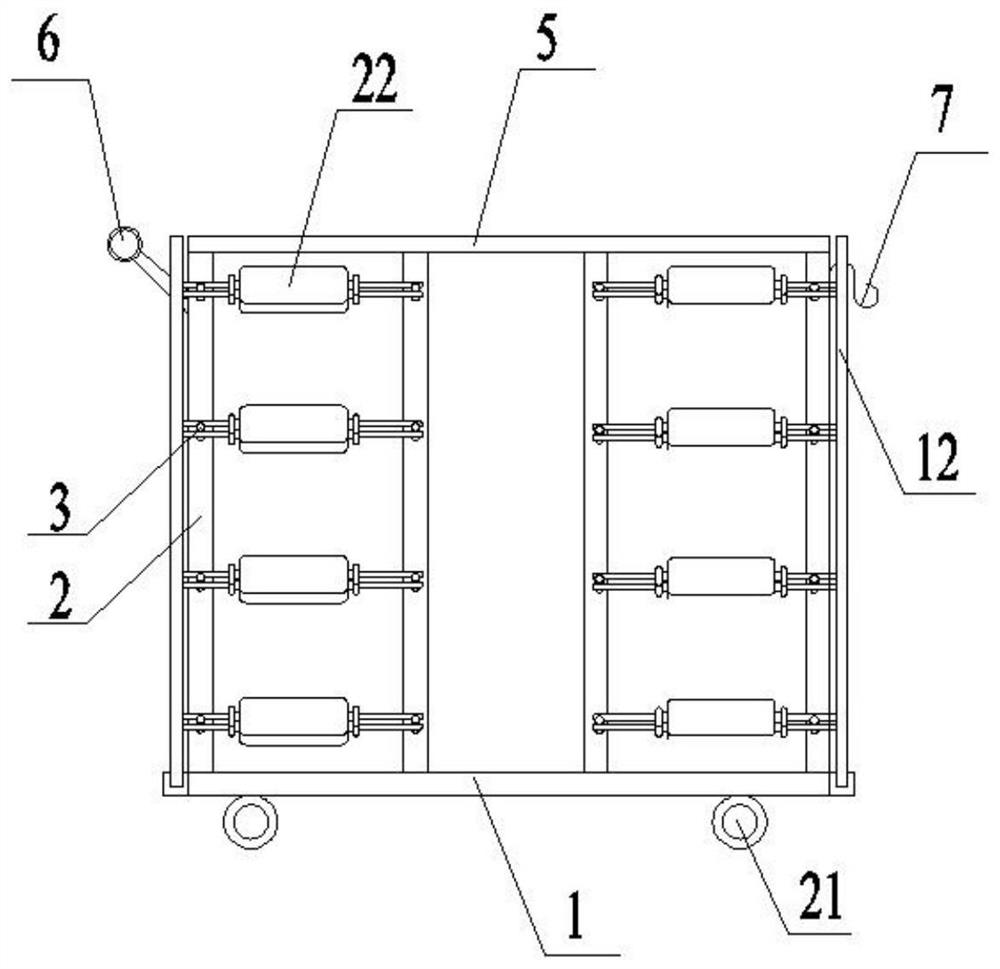

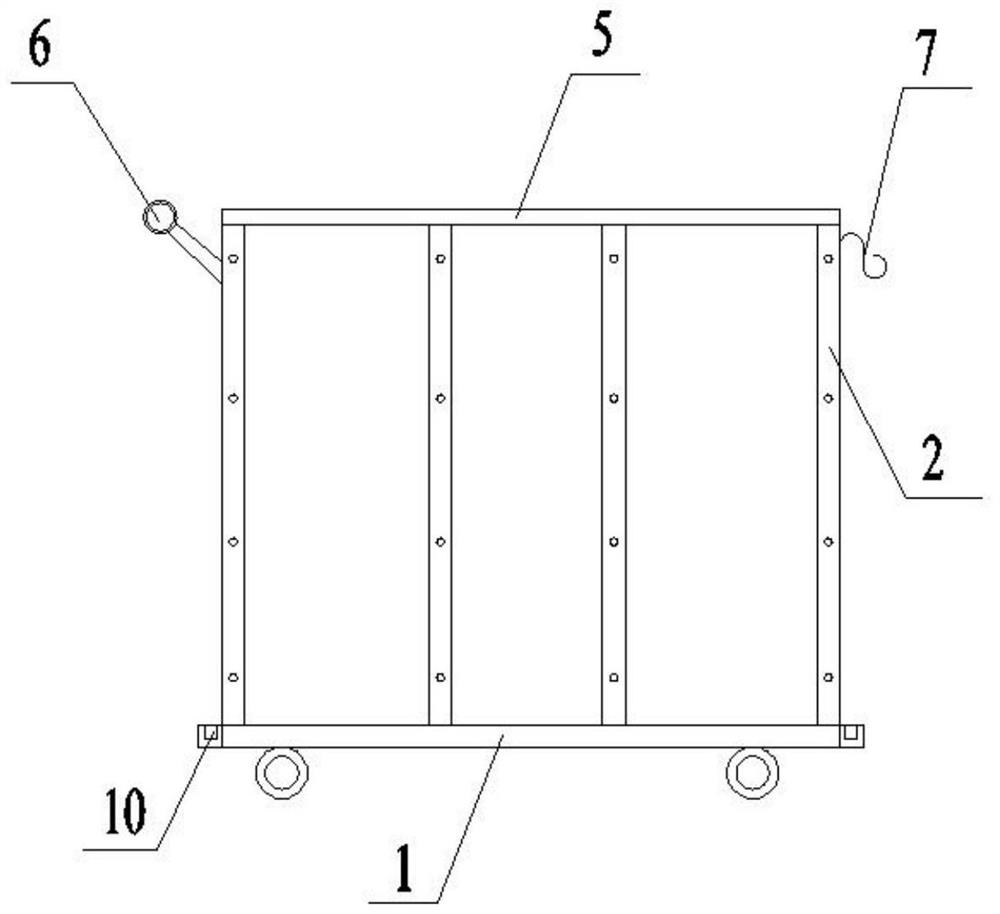

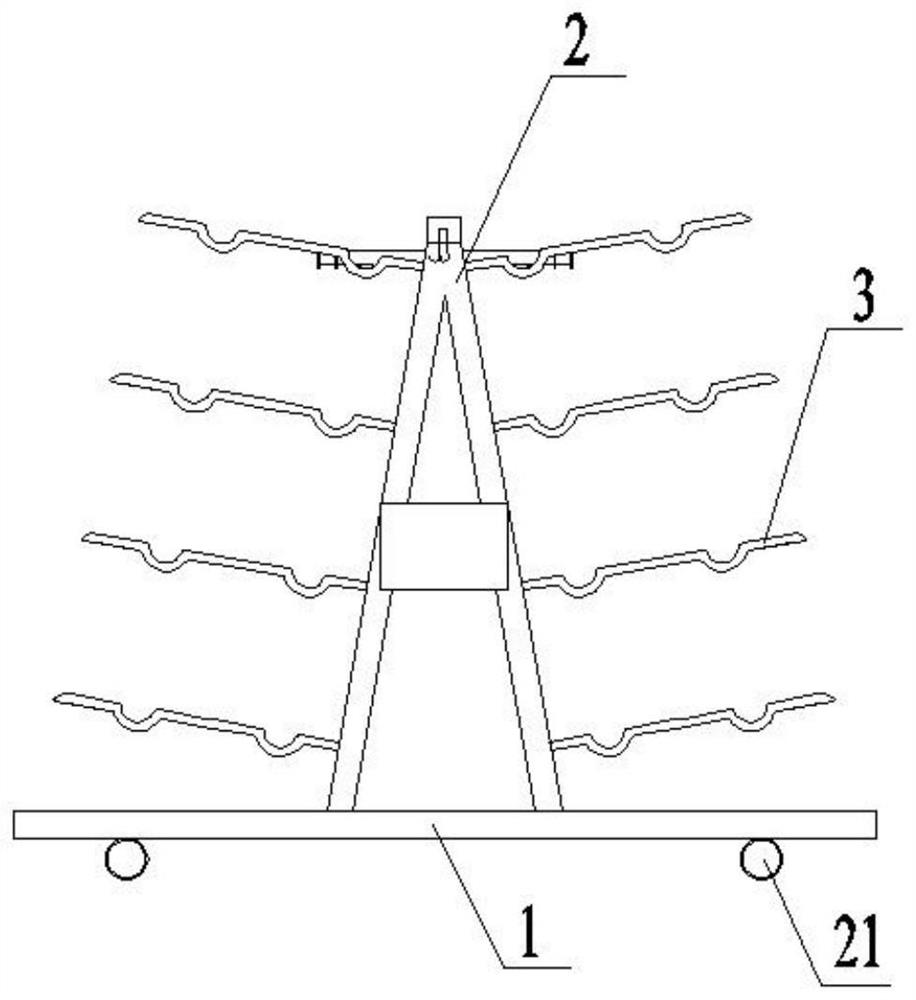

[0026] Such as Figure 1-5 As shown, this embodiment provides a double-sided turnover basket for placing motor rotors, including a bottom frame 1, a plurality of layered support frames 2 arranged in parallel on the bottom frame 1, and each layered support frame 2 is opposite to each other. A plurality of serpentine placement rods 3 are arranged on the outer walls of both sides. The main body of the serpentine placement rod 3 is cylindrical, and one end is fixedly connected with the layered support frame 2. The cylindrical main body is provided with a plurality of spacers for supporting and The accommodating groove 4 that fixes the electronic shaft of the motor and makes the rotor core of the motor completely suspended, and the serpentine placement rods 3 on the outer wall of the same side on the adjacent layered support frame 2 are distributed in parallel from top to bottom. Through a plurality of layered support frames arranged in parallel, and a plurality of serpentine place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com