Full-automatic conveying system and method for hazardous waste temporary storage warehouse

A conveying system, fully automatic technology, applied in the signal transmission system, storage device, transportation and packaging, etc., can solve the problem of reducing the space utilization rate of the temporary storage of hazardous waste, affecting the health coefficient of the staff in the temporary storage of hazardous waste, Physical and mental health and safety threats, etc., to achieve safe operation, improve space utilization, and improve the effect of health coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

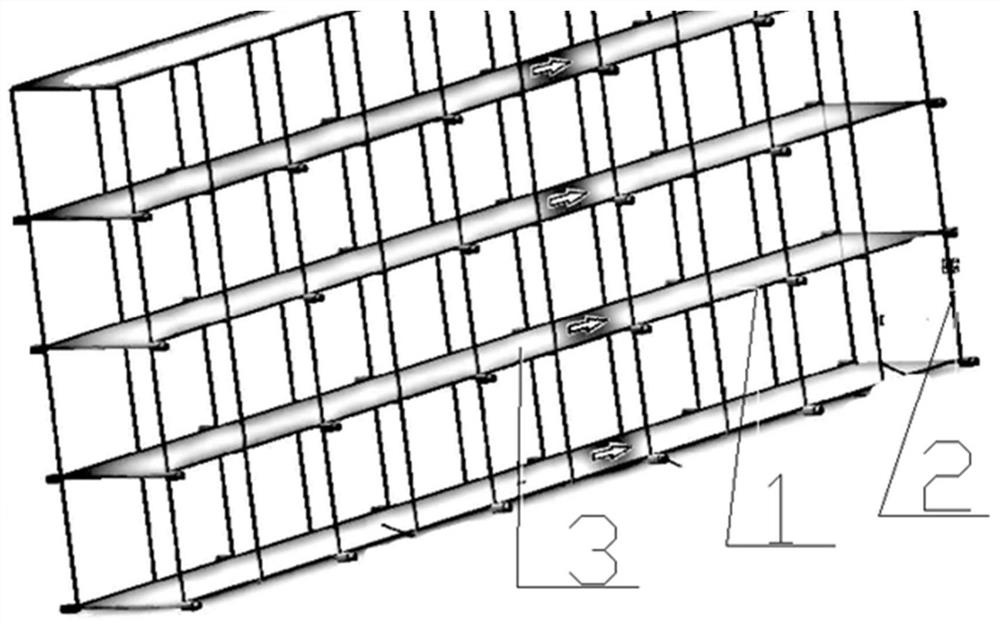

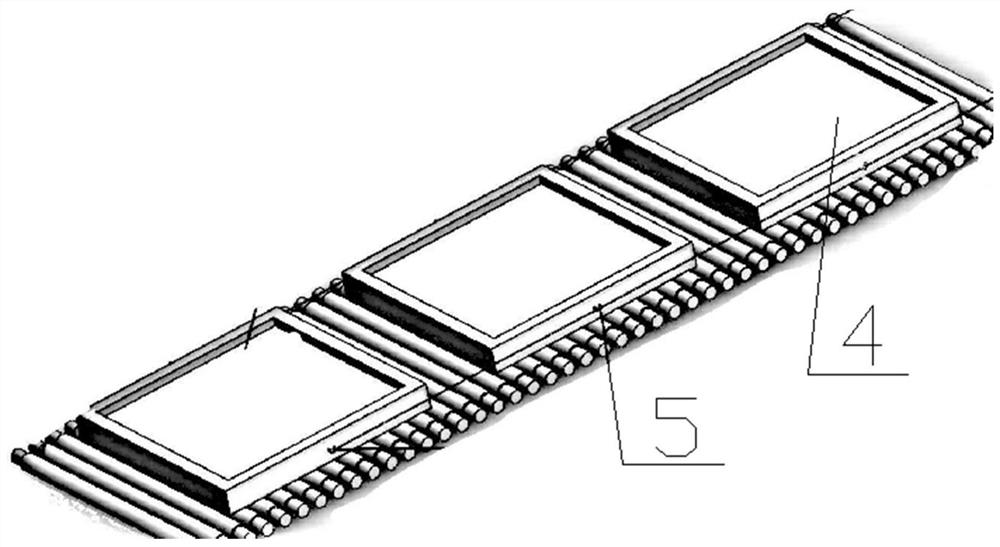

[0041] The existing hazardous waste temporary storage uses human-powered forklifts and ordinary shelves for hazardous waste ton bags. Staff need to enter and exit the hazardous waste temporary storage frequently, which poses a potential threat to physical and mental health and safety. To enter the forklift and the staff, it is necessary to leave enough space between the shelves to allow the forklift to pass through, which not only affects the health factor of the staff in the hazardous waste temporary storage, but also reduces the space utilization in the hazardous waste temporary storage .

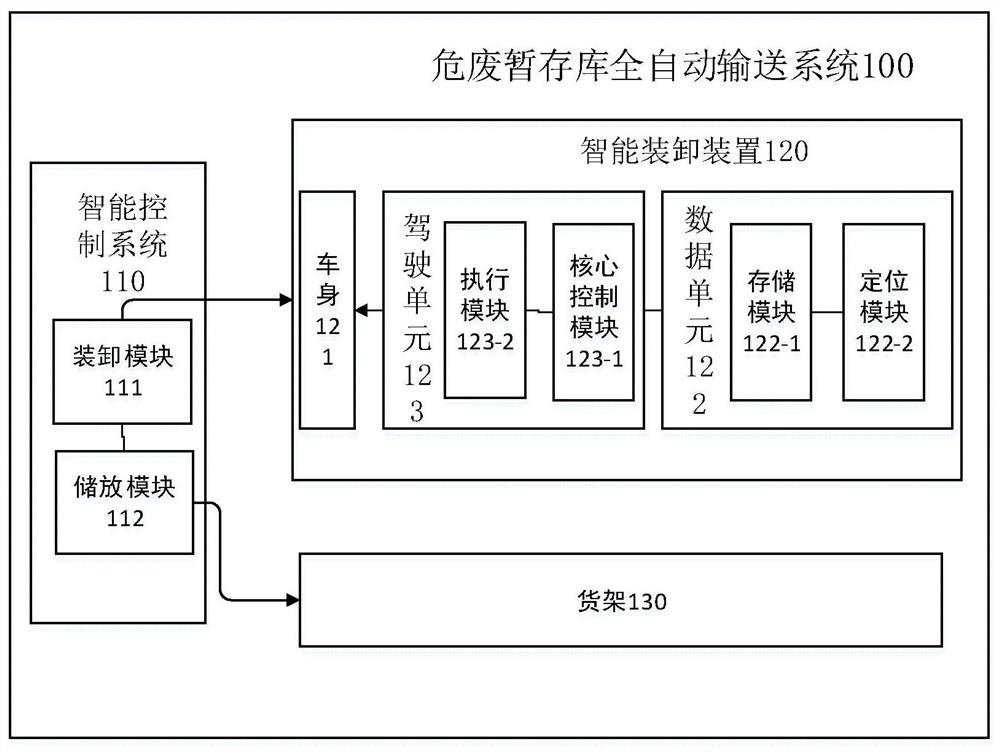

[0042] In view of the above problems, the present invention provides a fully automatic conveying system for hazardous waste temporary storage. The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0043] The following description of the exemplary embodiments is merely illustrative in nature and in no way is taken...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com