Spiral heat accumulating type gas electronic waste pyrolysis system

An electronic waste, regenerative technology, applied in special forms of dry distillation, indirect heating dry distillation, petroleum industry and other directions, can solve the problems of accelerating the pyrolysis speed of electronic waste, reducing the service life of coal plates, affecting the working process, etc. Sexual interspersed, increased intensity, and the effect of speeding up the work process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

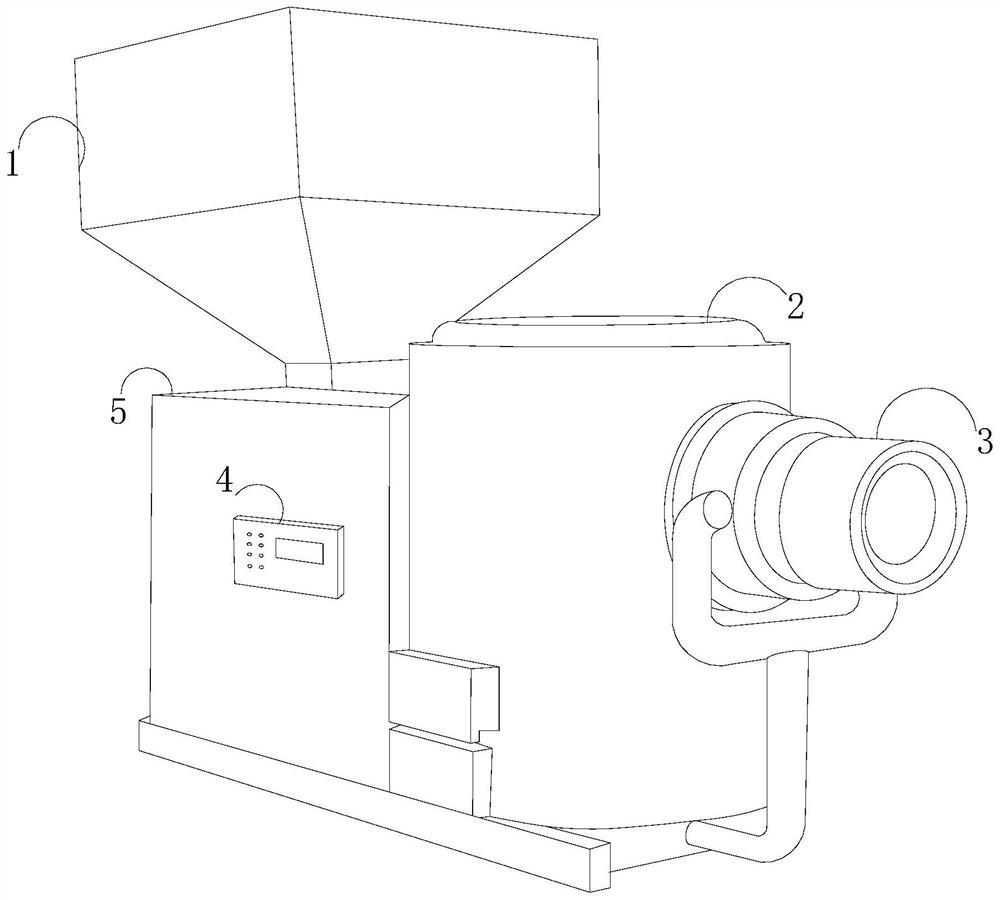

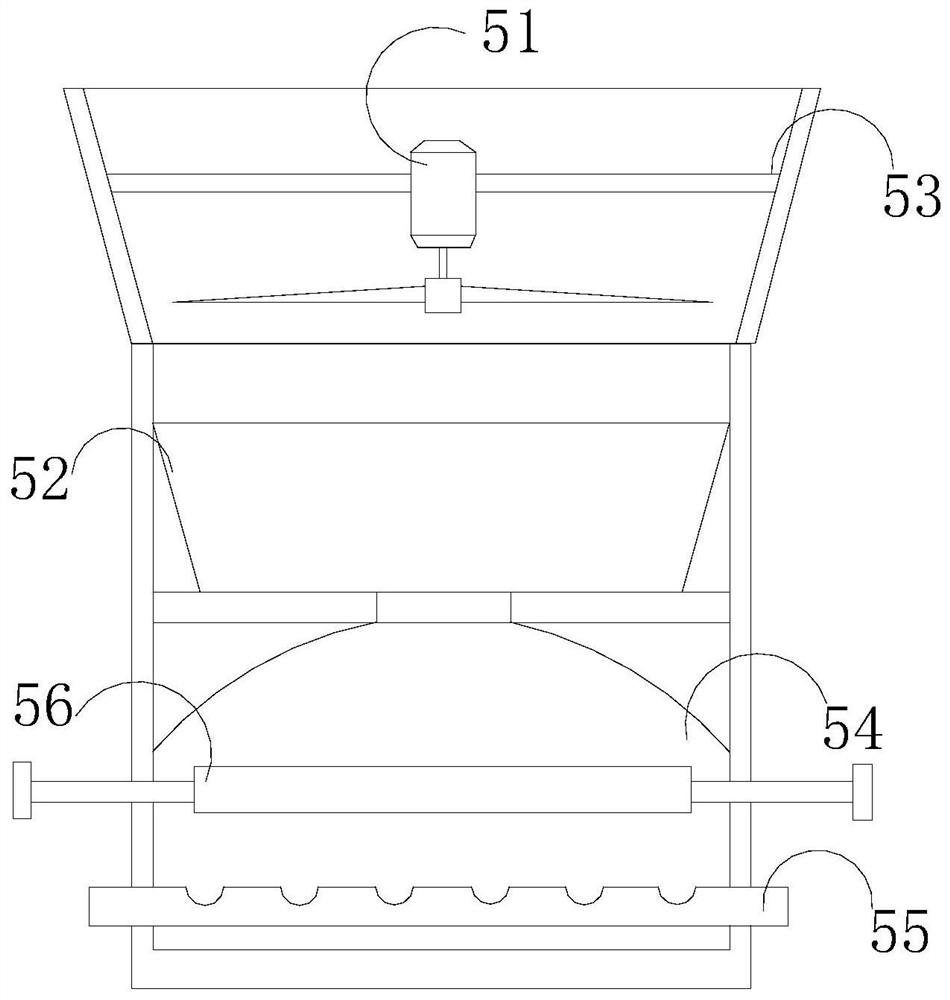

[0030] such as Figure 1- Figure 4 As shown, the invention provides a spiral heat storage type gas electronic waste pyrolysis system, which comprises a feed funnel 1, a reaction chamber 2, a discharge pipe 3, a control key 4, and a combustion chamber 5, wherein the feed funnel 1 is fixedly connected to the top of the combustion chamber 5, and the interior of the combustion chamber 5 is communicated with each other; the control key 4 is installed on the outer surface of the combustion chamber 5, and is electrically connected with the reaction chamber 2 through the combustion chamber 5; and the bottom conduit end of the reaction chamber 2 extends to the receiving port of the discharge pipe 3. The combustion chamber 5 comprises a radiating fan 51, a pyrolysis regulating pot 52, a partition 53, a heat storage port 54, an aeration ring 55 and a deformation tool 56. The middle of the partition 53 is provided with the radiating fan 51, and the bottom fan of the radiating fan 51 is aligned...

Embodiment 2

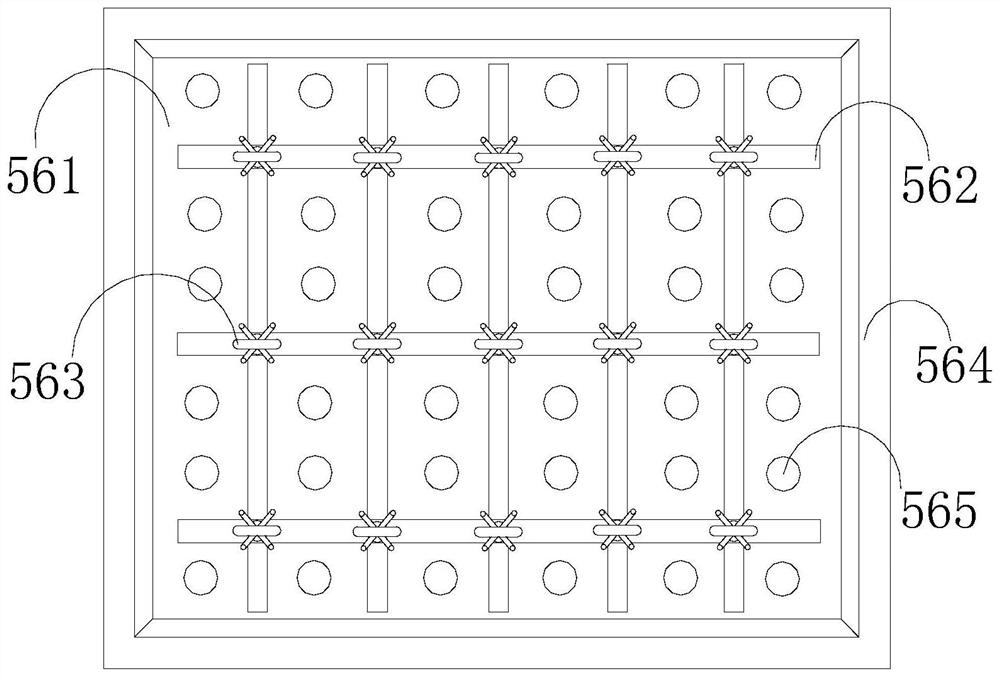

[0032] such as Figure 5- Figure 7 As shown, on the basis of Embodiment 1, the present invention combines the cooperation of the following structural components, and the sliding swing groove 634 includes a guide rail channel 341, an alignment support plate 342, and an end sleeve holder 343. Two end sleeve holders 343 with the same structure are embedded and fixed in the guide rail channel 341, and two alignment support plates 342 with the same structure are installed at their ports, and the end sleeve holders 343 are buckled with the clamping ends of the arc-shaped clamping posts 636. The clamping device 631 comprises a sleeve member 1a1, an accommodating socket 1a2, a running-in layer 1a3, a pressure-bearing structure 1a4, a tip contact angle 1a5 and a sliding groove 1a6, wherein the top of the sleeve member 1a1 is welded and connected with the tip contact angle 1a5 movably crossing the bottom of the frame 562, and grooves with sliding grooves 1a6 on both sides are movably engaged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com