High/low temperature complex atmosphere environment loading device

A loading device and low-temperature environment technology, applied in the field of precision instruments, can solve the problems of difficult in-situ monitoring, poor space compatibility, narrow temperature loading range, etc., and achieve the effects of convenient disassembly and installation, anti-oxidation, and good integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

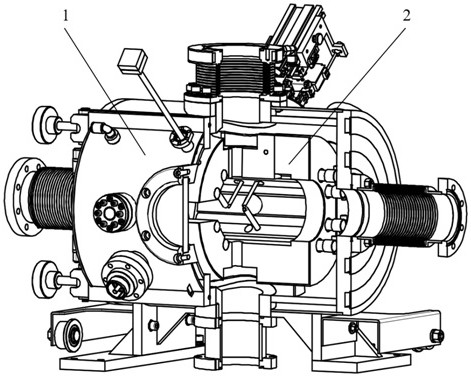

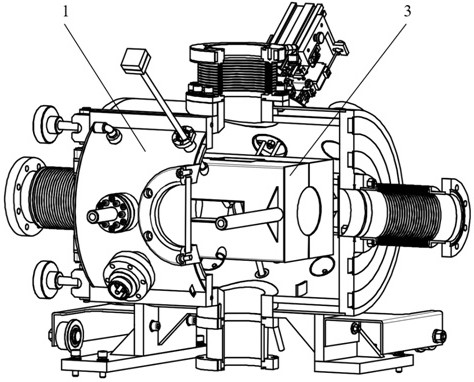

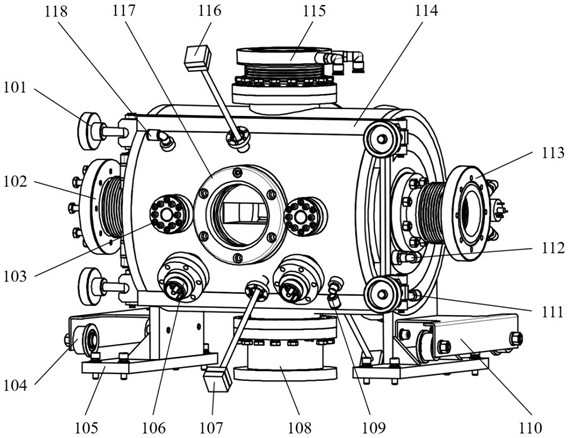

[0039] see Figure 1 to Figure 14 As shown, the high / low temperature complex atmosphere environment loading device of the present invention adopts annular uniformly distributed silicon molybdenum rod radiation heating to realize the construction of high temperature environment (RT~1200°C), and uses circulating cold medium radiation refrigeration to realize low temperature environment (-70°C ~RT), and achieve real-time temperature measurement and feedback through thermocouple components. The front and rear sides of the device are equipped with in-situ observation windows, which can flexibly integrate various high-resolution in-situ imaging equipment to realize in-situ monitoring of the macro and micro topography of the surface of the material sample to be tested; the upper, lower and left sides of the device , The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com