High-voltage vacuum switch fault early warning method and system

A vacuum switch and fault warning technology, applied in high voltage/high current switches, high voltage air circuit breakers, electric switches, etc., can solve problems such as electric shock accidents and being in a live state, and achieve the effect of eliminating potential safety hazards of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

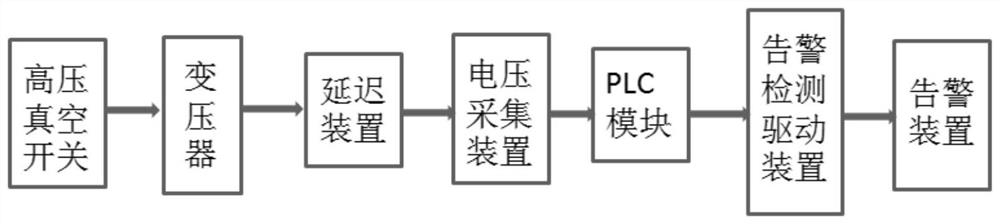

[0020] The technical problem to be solved by the present invention is that after the high-voltage vacuum switch is opened, there is still a voltage signal, which may cause electric shock accidents. The present invention provides a high-voltage vacuum switch failure early warning method, which uses a combination of a PLC module and an alarm device The method realizes the detection of the voltage signal and the alarm of the abnormal state after the high-voltage vacuum switch is opened, including the following steps:

[0021] Step A. In the open state of the high-voltage vacuum switch, collect the voltage signal output by the high-voltage vacuum switch, and perform step-down processing to obtain the voltage signal after step-down, and then enter step B.

[0022] In the practical application of the above step A, it is furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com