Thermoelectric power generation stove power supply system and charging management method thereof

A technology of thermoelectric power generation and power supply system, applied in the direction of generator/motor, battery overcharge protection, battery circuit device, etc., can solve the problems of waste, short life, increased use cost, etc., and achieve the effect of frequently replacing batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

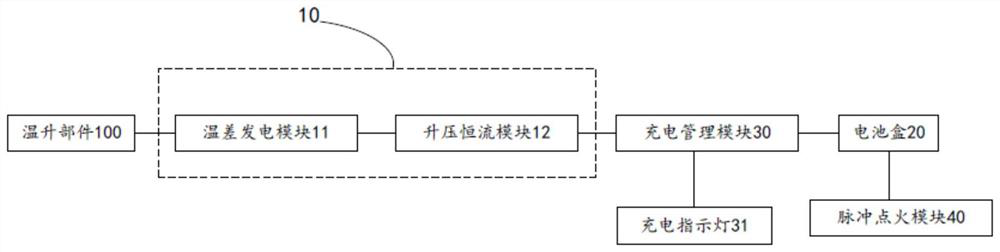

[0028] An embodiment of a cooker power supply system for thermoelectric power generation:

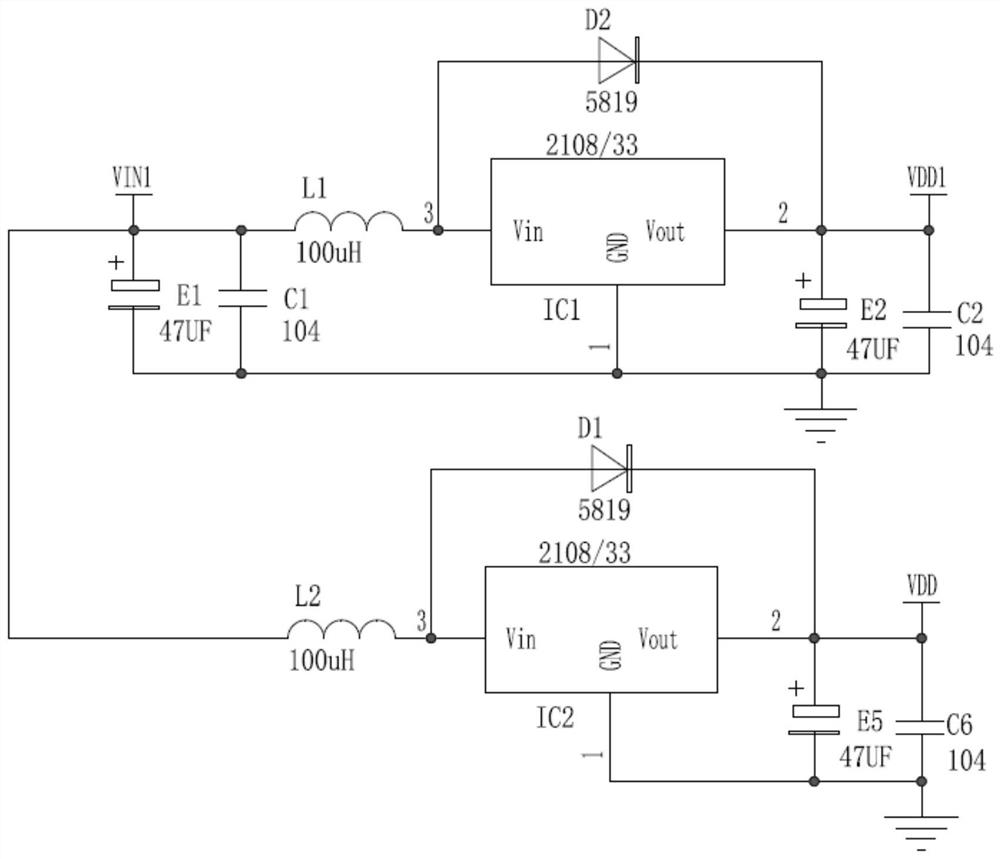

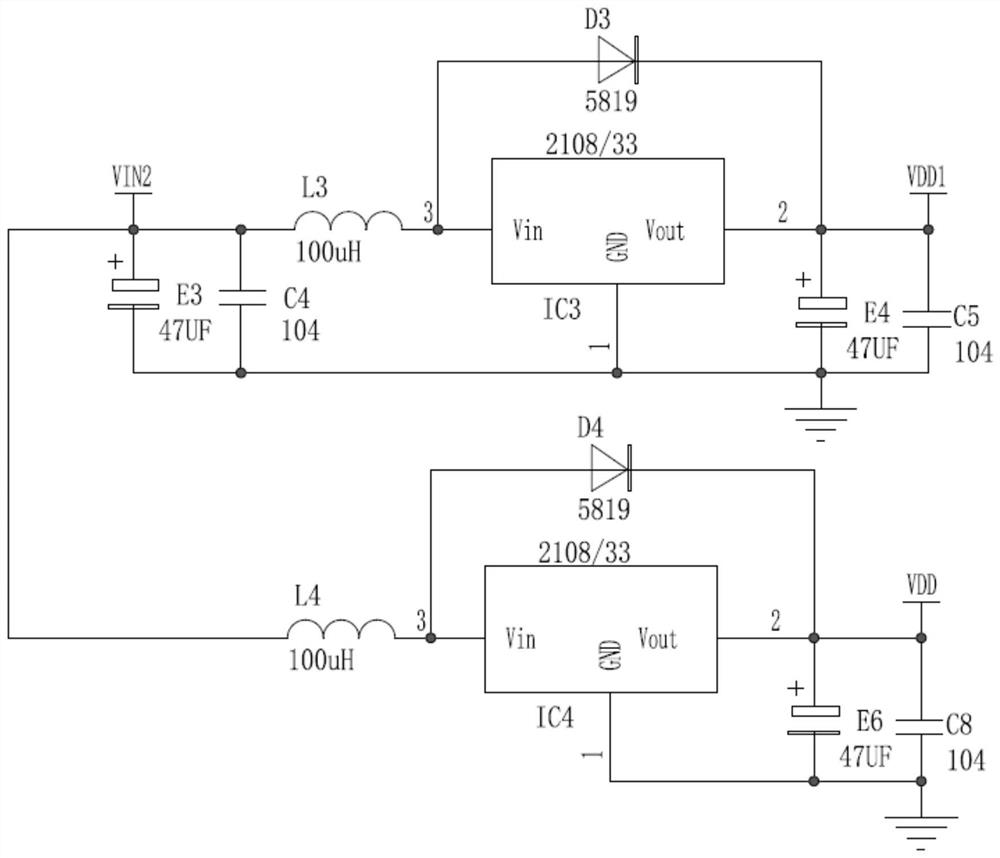

[0029] see figure 1 The cooker power supply system for thermoelectric power generation of the present invention includes a cooker main body, on which a thermoelectric power generation unit 10, a battery box 20 for power supply and ignition, a charging management module 30 connected to the thermoelectric power generation unit 10 and the battery box 20, and The pulse ignition module 40 connected to the battery box 20, the thermoelectric power generation unit 10 is installed on the temperature rise component 100 of the gas stove main body, and is used to convert heat energy into electric energy according to the temperature difference signal of the temperature rise component 100, and the battery box is supplied by the generated electric energy. 20 for charging, and the charge management module 30 is used to control the forward charging of the battery box 20, and control the thermoelectric p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com