Circulating water filtering system

A technology of circulating water filtration and filter screen, applied in fish farming, application, animal husbandry and other directions, can solve the problems of large space, limited model, irregular shape, etc., to achieve easy installation and disassembly, increase filter space , the effect of simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

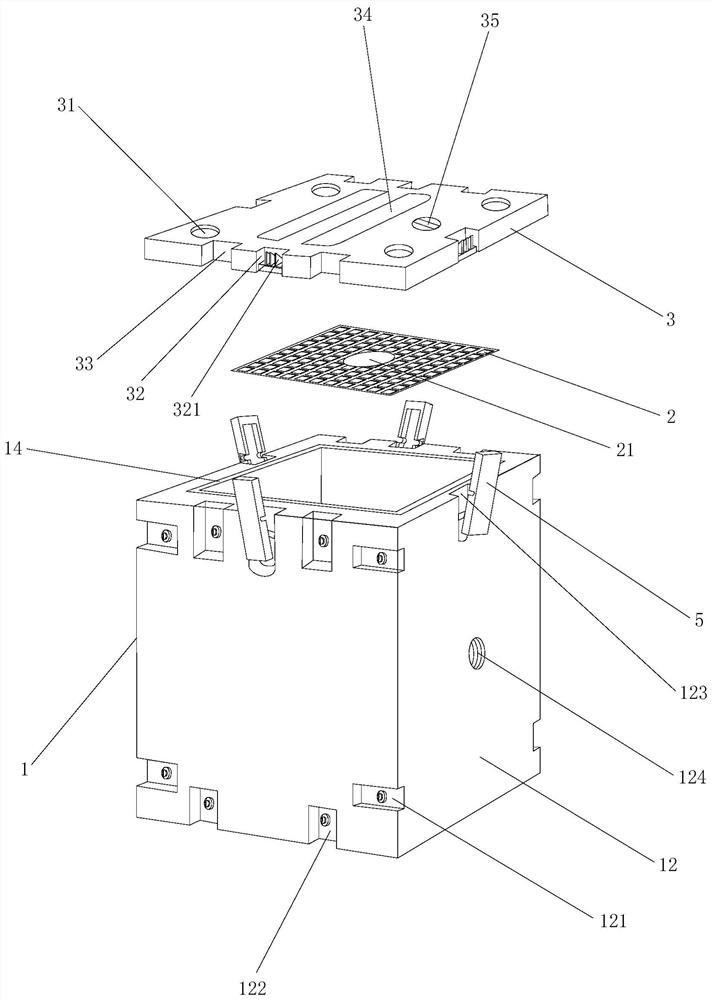

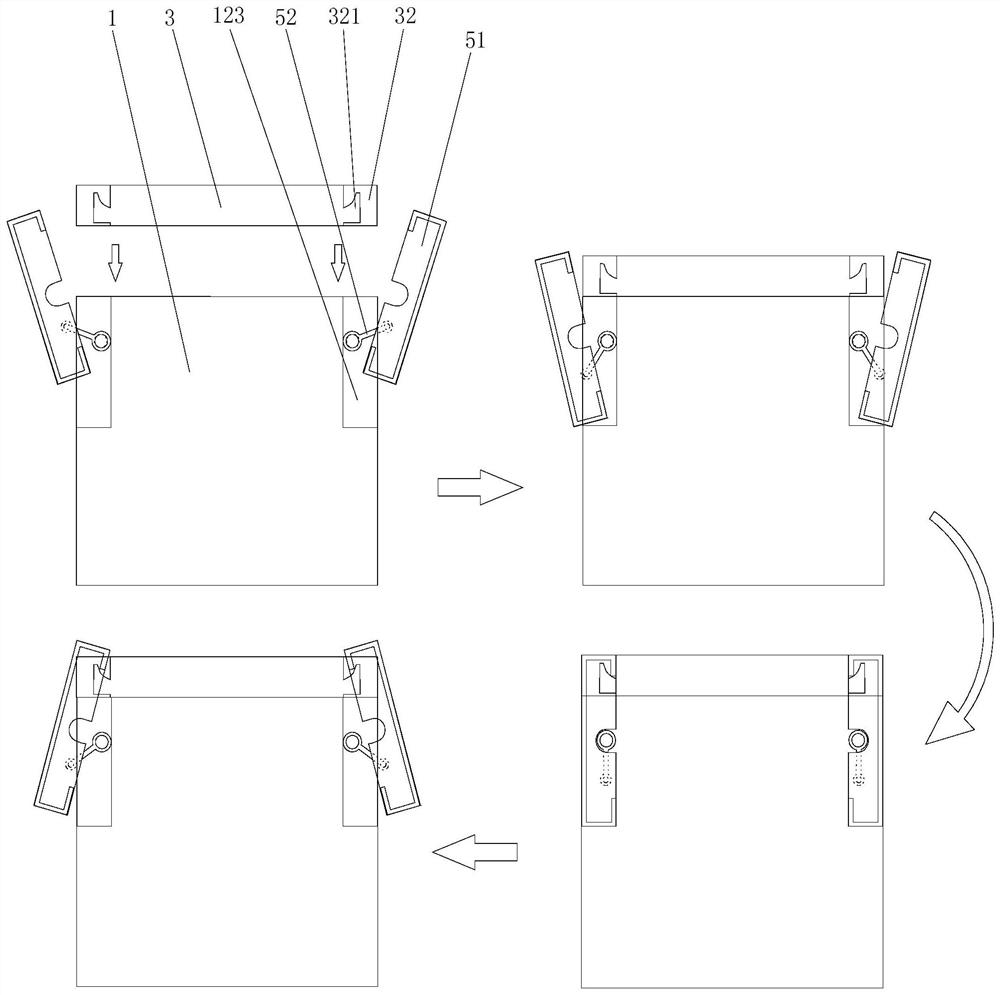

[0029] Such as Figures 1 to 8 As shown, the circulating water filtration system of Embodiment 1 of the present invention is assembled by one or more than one cube filter barrels in a linked manner.

[0030] The filter bucket in Example 1 of the present invention includes a bucket body 1 , a filter screen 2 , a bucket cover 3 , a bucket body buckle 4 , a bucket lid buckle 5 and a water conduit 6 .

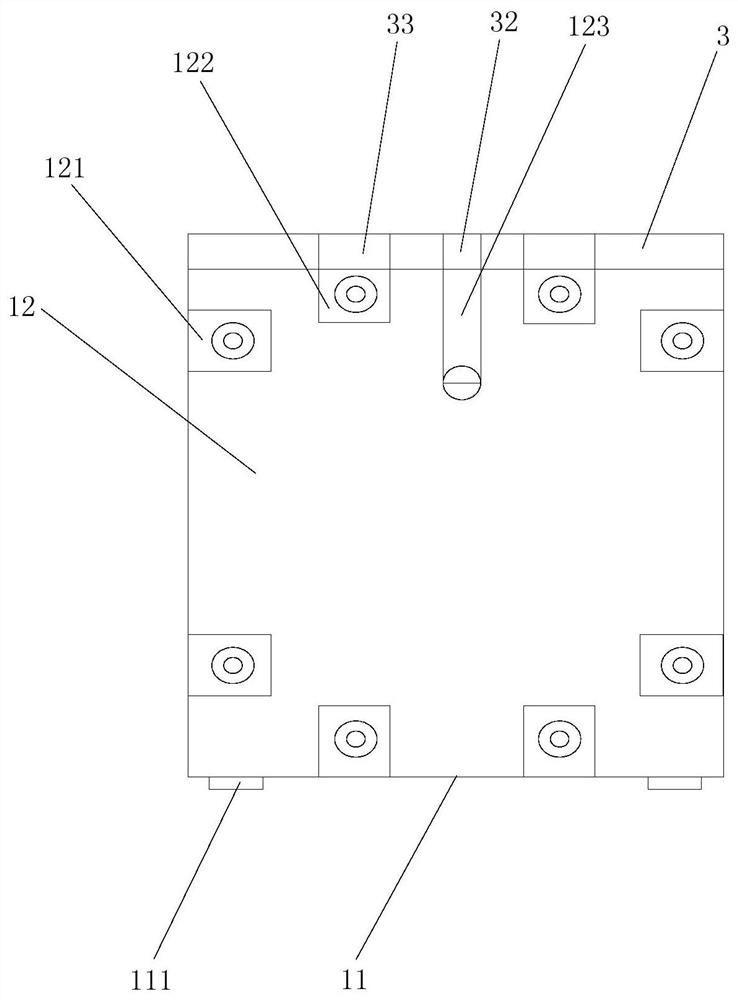

[0031] The bucket body 1 is a square integral structure, which includes a bucket bottom 11 and a bucket wall 12; the bucket bottom 11 is a square plate structure, and the four corners of the outer bottom are symmetrically provided with circular protrusions 111; the bucket wall 12 has four And vertically connected to the front, rear, left and right sides of the bucket bottom 11 respectively, the four bucket walls 12 and the bucket bottom 11 form an accommodating space; The left and right end faces of the barrel wall 12 are matched with a pair of horizontal direction barrel link gro...

Embodiment 2

[0038] Such as Figure 9 As shown, the circulating water filtration system of Embodiment 2 of the present invention is assembled by one or more cuboid filter barrels in a linked manner.

[0039] Such as Figure 9 As shown, the filter bucket in embodiment 2 of the present invention also has the following subtle differences in structural design compared with the filter bucket in embodiment 1 of the present invention:

[0040] (1) In Embodiment 2 of the present invention, the upper part of the barrel wall 12 on the left and right sides of the barrel body 1 is only provided with a mounting groove 123 in the center, and the lower part of the barrel wall 12 on the front side of the barrel body 1 is evenly arranged with four vertical grooves along the horizontal direction. The barrel connecting groove 122 in the straight direction, the barrel 1 is provided with two pipe installation holes 124 in the middle area of the barrel wall 12 on the front side, and the four corners of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com