Dissolving tank capable of avoiding raw material deposition and for processing calamine powder

A technology of calamine powder and dissolving tank, which is applied in the directions of dissolving, mixers with rotary stirring devices, mixers, etc., can solve the problems of raw material deposition, the influence of calamine powder processing, the inability of raw materials to dissolve effectively, etc. Dissolution efficiency, the effect of slowing down the falling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

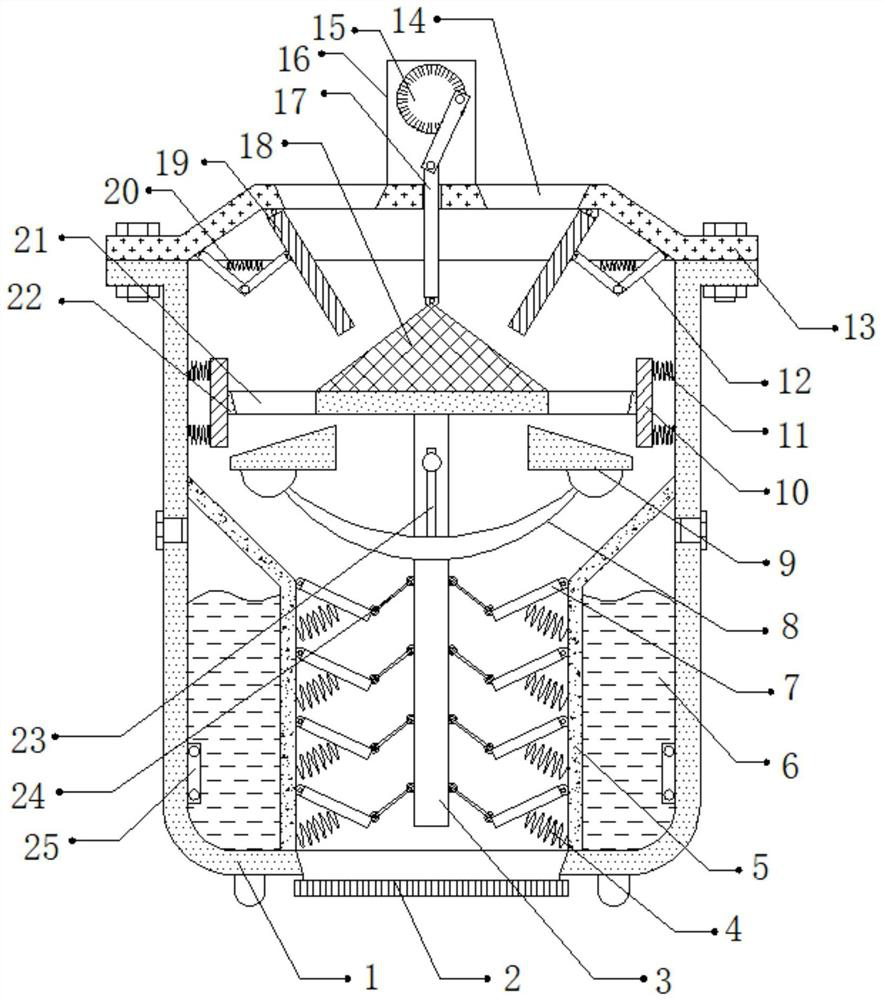

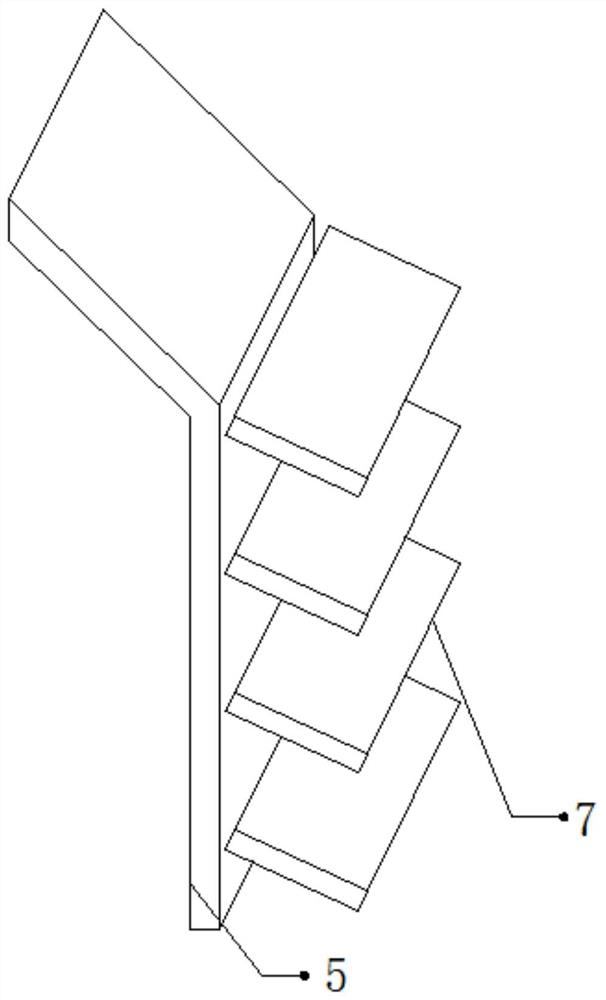

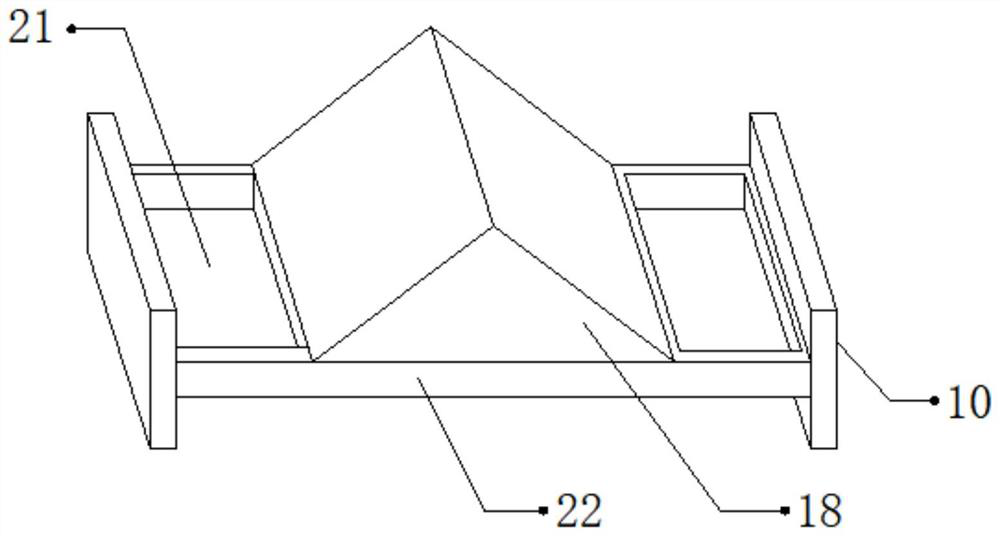

[0028] refer to Figure 1-3 , a dissolving tank for calamine powder processing to avoid raw material deposition, comprising a dissolving tank body 1, a bottom outer wall of the dissolving tank body 1 is provided with a discharge opening, and the inner wall of the discharge opening is provided with a sealing cover 2, and the dissolving tank body 1 The top outer wall of the tank body 1 is connected with a tank cover 13 by bolts, and both sides of the top outer wall of the tank cover 13 are provided with feed inlets 14, and the inner walls of both sides of the dissolution tank body 1 are connected with a second spring 11 by bolts, and the second One side of the outer wall of the spring 11 is connected with a protective plate 10 by bolts, and a support plate 22 is connected between the opposite outer walls of the two protective plates 10 by bolts, and both sides of the top outer wall of the support plate 22 are provided with openings 21 , the bottom outer wall of the support plate...

Embodiment 2

[0038] refer to Figure 4 , a dissolution tank for calamine powder processing that avoids raw material deposition. Compared with Example 1, the outer walls of both sides of the dissolution tank body 1 are connected with protective pads by bolts, and one side of the outer wall of the protective pad is connected by bolts. A vibrating motor 26 is connected, and the raw material debris adhering to the inside of the dissolving tank body 1 can be processed through the vibration of the vibrating motor 26, so that the inside of the dissolving tank body 1 is cleaned.

[0039] Working principle: when in use, the calamine powder that needs to be dissolved is filled into the interior of the dissolution tank body 1 through the feeding port 14, and when the raw material falls into the feeding plate 19, the gravity of the raw material will cause the feeding plate 19 to Fluctuates under the action of the third spring 20, so as to slow down the falling speed of the raw materials and at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com