Indoor missile disassembling robot and working method thereof

A technology of robots and steering gears, applied in the field of robots, can solve the problems of easy mistakes and time-consuming manual processing, and achieve the effect of ensuring accuracy, high efficiency, safe and efficient bomb disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

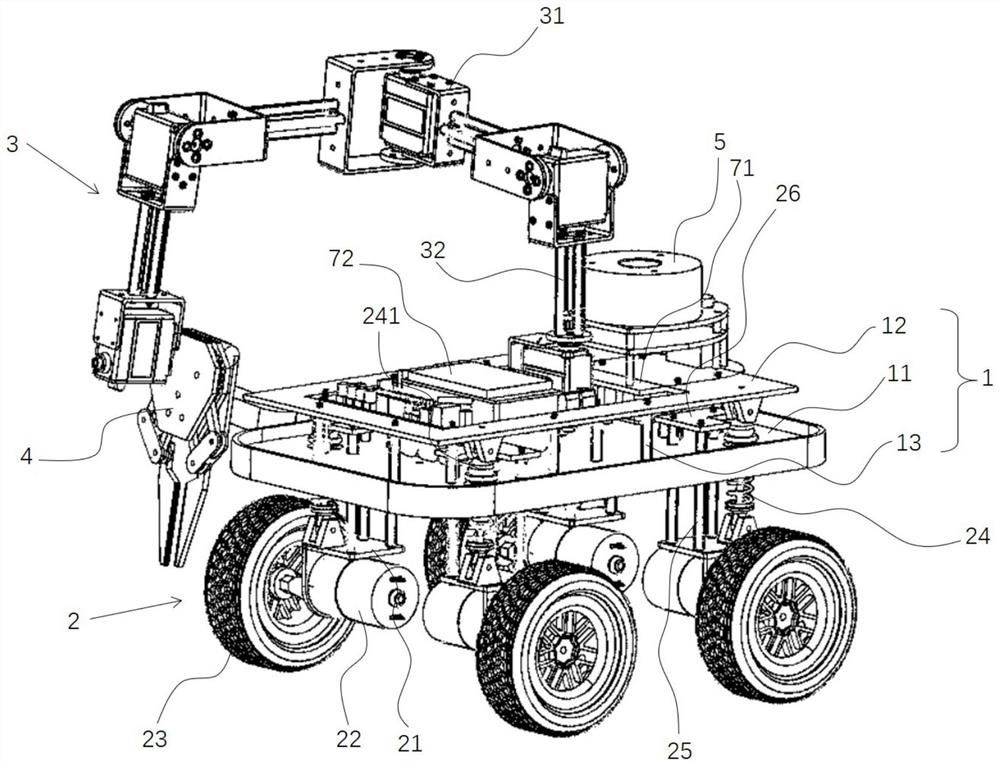

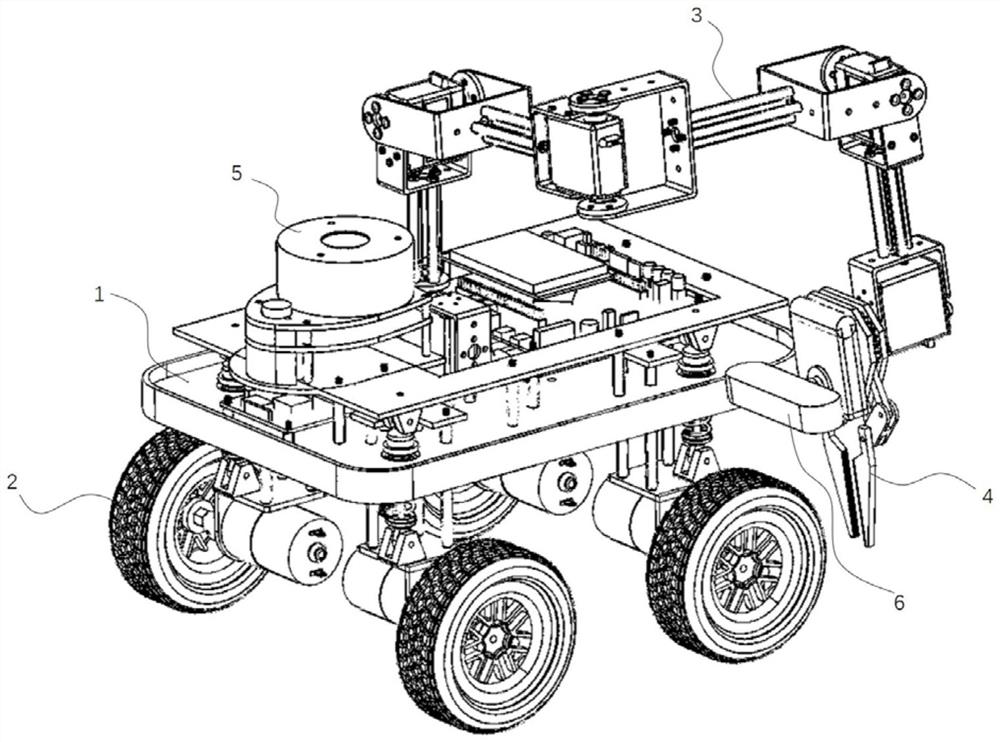

[0019] Such as figure 1 and 2 As shown, the present invention provides an indoor bomb disposal robot, including a bracket assembly 1, four sets of drive assemblies 2, a mechanical arm 3, mechanical scissors 4, a laser radar 5, a camera 6 and a control unit.

[0020] The bracket assembly 1 includes a bracket body 11 and a protective plate 12 .

[0021] The frame body 11 has a bottom plate. Specifically, the frame body 11 is in the shape of a plate, and there are side walls around the bottom plate to further protect the components inside it.

[0022] The protective plate 12 is in the shape of a frame, and the protective plate 12 is fixed on the top of the frame body 11 by several vertically arranged protective support rods 13 .

[0023] The four groups of drive assemblies 2 are distributed at the top corners of a rectangle.

[0024] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com