Stable modified asphalt regenerant based on epoxy bio-oil and preparation method of stable modified asphalt regenerant

A modified asphalt and biological regeneration technology, which is applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of insufficient regeneration capacity, stability and penetration capacity of regenerants, and achieve the goal of being suitable for large-scale application and practicality Strong, benefit-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

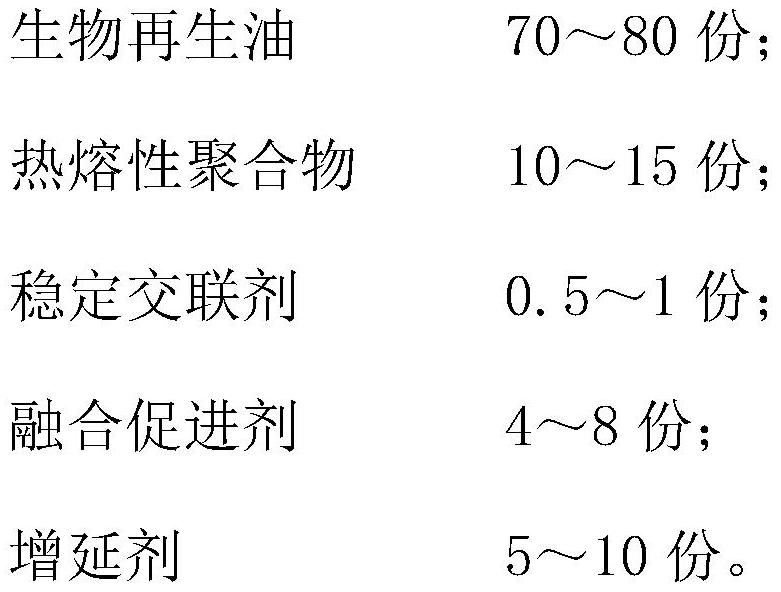

[0027] Taking the preparation of 100g of stable modified asphalt regenerant as an example, each raw material is weighed, and its quality is as follows:

[0028]

[0029]

[0030] The biologically regenerated oil used in this example is epoxidized soybean oil, which is obtained from soybean oil refining, the used hot-melt polymer is high-viscosity modifier TPS imported from Japan, and the used stable cross-linking agent is produced by Shell Company. Sulfur powder, the fusion accelerator used is limonene obtained by the daily chemical environmental protection company through the extraction of lemon peel, and the extension agent used is dibutyl phthalate.

[0031] The preparation method of the stable modified asphalt regenerant based on epoxy bio-oil that this example implements, comprises the steps:

[0032] 1) take by weighing raw material by the mass fractions shared by each component, the mass fractions shared by each component are: epoxidized soybean oil 75g, TPS15g; S...

Embodiment 2

[0038] Taking the preparation of 100g of stable modified asphalt regenerant as an example, each raw material is weighed, and its quality is as follows:

[0039]

[0040]

[0041] The biological regeneration oil used in this example is epoxidized cotton oil, which is obtained from cottonseed oil refining, and the used hot-melt polymer is the high viscosity modifier HVA produced by Jiangsu Subote New Materials Co., Ltd. The cross-linking agent is sulfur powder produced by Shell Company, the fusion accelerator used is limonene obtained by refining orange peels by the Daily Chemical Environmental Protection Company, and the extension agent used is dioctyl phthalate.

[0042] The preparation method of the stable modified asphalt regenerant based on epoxy bio-oil that this example implements, comprises the steps:

[0043] 1) The raw materials are weighed according to the mass fractions occupied by each component, and the mass fractions occupied by each component are: epoxy cot...

Embodiment 3

[0049] Taking the preparation of 100g of stable modified asphalt regenerant as an example, each raw material is weighed, and its quality is as follows:

[0050]

[0051] The biological regeneration oil used in this example is epoxidized peanut oil, which is obtained from peanut oil refining. The hot-melt polymer used is high-viscosity modifier TPS imported from Japan. The fusion accelerator used is limonene obtained by the daily chemical environmental protection company through the extraction of orange peel, and the used extension agent is dibutyl phthalate.

[0052] The preparation method of the stable modified asphalt regenerant based on epoxy bio-oil that this example implements, comprises the steps:

[0053] 1) take by weighing the raw material by the mass fraction shared by each component, the mass fraction shared by each component is: epoxy soybean peanut oil 70g, TPS15g; Sulfur 0.8g, limonene 7.2g; Dibutyl phthalate 7g;

[0054] 2) Heat the epoxidized peanut oil to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com