A method for dyeing polyester at room temperature

A polyester, room temperature technology, applied in the field of polyester room temperature dyeing, can solve the problems of large water consumption and energy consumption, and achieve the effect of less water consumption and low dyeing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

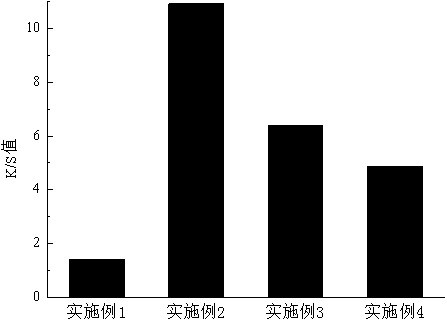

Embodiment 1

[0025] A method for dyeing polyester at room temperature, the specific steps are as follows:

[0026] The first step, the alkali weight reduction treatment of the polyester fabric: the polyester fabric is treated at 80°C for 40 minutes at a bath ratio of 10:1, sodium hydroxide 10g / L, accelerator 1631 1 g / L, washed in hot water and cold water , after drying for later use;

[0027] The second step, room temperature dyeing of polyester fabrics: add 1 mmol of trimesic acid to 5 mL of 1M sodium hydroxide, ultrasonically treat for 5 min, control the pH to 7, and obtain solution A; 0.2 g of alkali-reduced polyester The fabric was added to solution A; 2 mmol of ferrous sulfate heptahydrate was added to 20 mL of distilled water, and ultrasonic treatment was performed for 5 min to obtain solution B; the solution B was added dropwise at a rate of 50-60 drops / min to the polyester fabric soaked In the solution A, the reaction was shaken at room temperature for 40 minutes. After the reacti...

Embodiment 2

[0029] A method for dyeing polyester at room temperature, the specific steps are as follows:

[0030] (1) Alkali weight reduction treatment of polyester fabric: The polyester fabric was treated at 80°C for 60 min at a bath ratio of 20:1, sodium hydroxide 15g / L, and accelerator 16311.5 g / L. Wash in hot water, cold water, dry and set aside.

[0031] (2) Room temperature dyeing of polyester fabric: Add 1 mmol of trimesic acid to 5 mL of 1M sodium hydroxide, ultrasonicate for 5 min, control the pH to 6, and obtain solution A; 0.6 g of polyester fabric after alkali reduction Add to solution A; Add 6 mmol ferrous sulfate heptahydrate to 40 mL of distilled water, and ultrasonically treat for 5 min to obtain solution B; Add solution B dropwise to the solution soaked in polyester fabric at a rate of 50-60 drops / min In A, shake the reaction at room temperature for 120 min. After the reaction, the polyester fabric is taken out, washed with water, soaped, washed with water, and dried. T...

Embodiment 3

[0033] A method for dyeing polyester at room temperature, the specific steps are as follows:

[0034] (1) Alkali weight reduction treatment of polyester fabric: The polyester fabric was treated at 80°C for 50 minutes at a bath ratio of 15:1, sodium hydroxide 10g / L, and accelerator 16311 g / L. Wash in hot water, cold water, dry and set aside.

[0035] (2) Room temperature dyeing of polyester fabric: Add 2 mmol of trimesic acid to 10 mL of 1M sodium hydroxide, ultrasonicate for 5 min, and control the pH to 8 to obtain solution A; 0.3 g of polyester fabric after alkali reduction Add to solution A; add 6 mmol ferrous sulfate heptahydrate to 40 mL of distilled water, and ultrasonically treat for 10 min to obtain solution B; add solution B dropwise to the solution soaked in polyester fabric at a rate of 50-60 drops / min In A, shake and react at room temperature for 90 minutes. After the reaction, the polyester fabric is taken out, washed with water, soaped, washed with water, and dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com