Oil well induced flow system and induced flow process

An oil well and thin oil technology, applied in the field of oil well blowout induction system and blowout induction process, can solve problems such as temperature drop, incomplete blowout, and increase of wellhead back pressure, so as to reduce viscosity and density, avoid incomplete blowout, Guaranteed smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

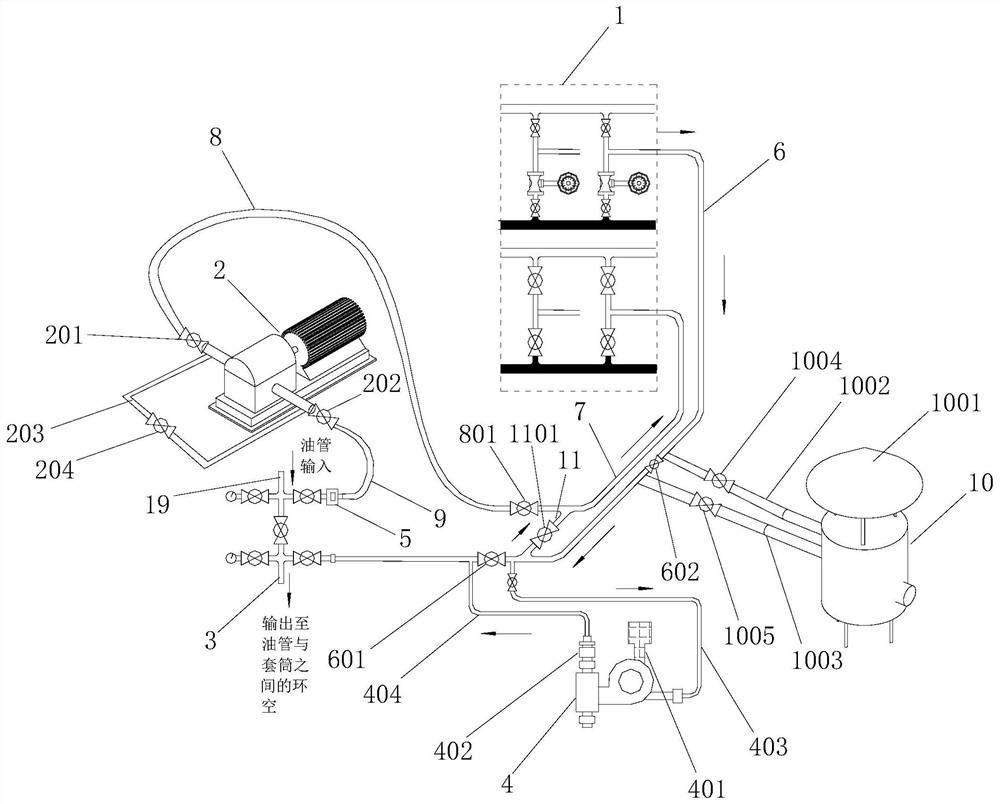

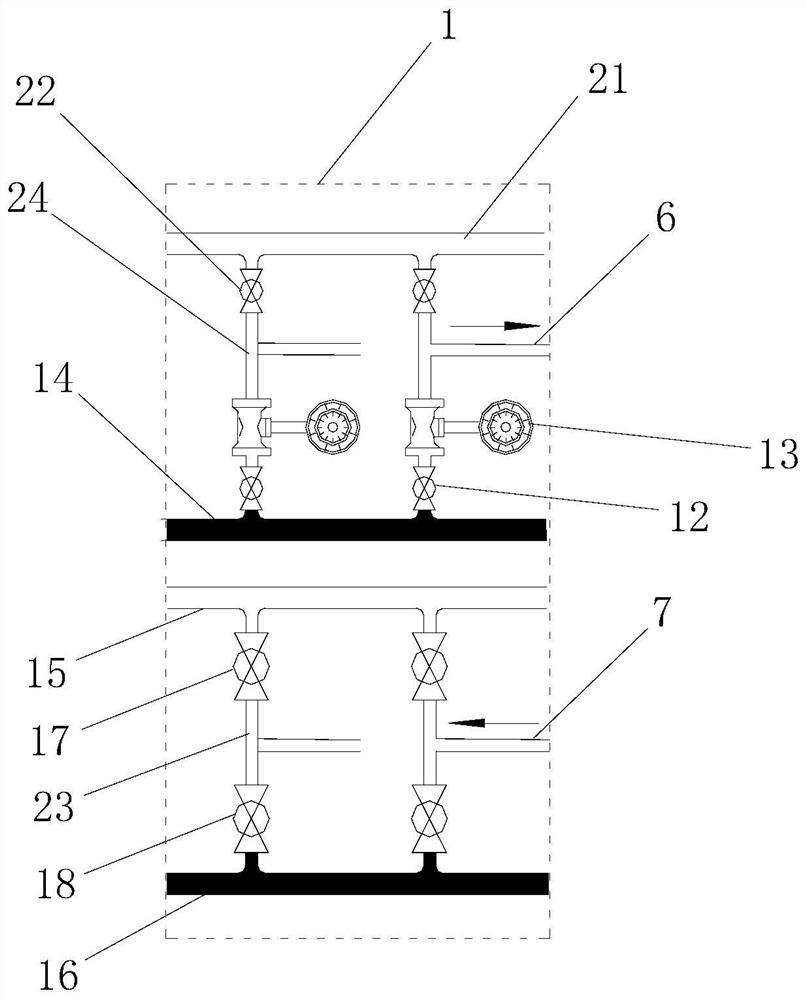

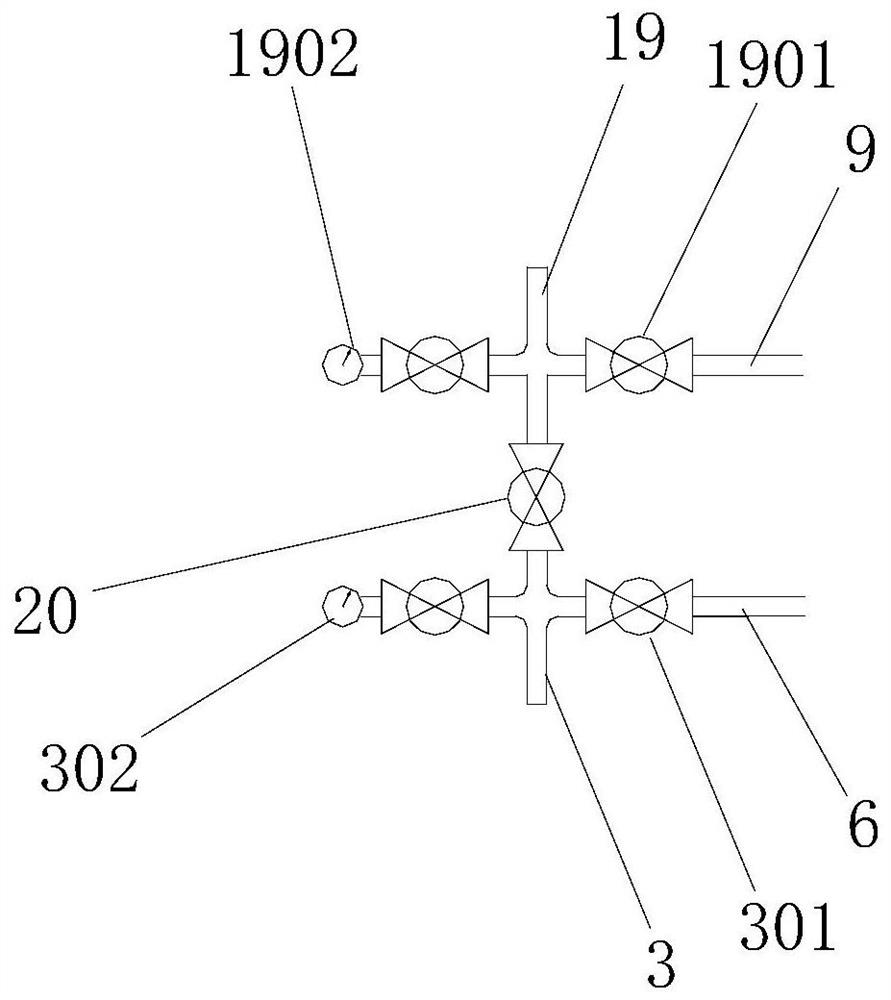

[0043] Such as Figure 1 to Figure 4 As shown, the present invention provides an oil well induced blowout system. The oil well induced blowout system includes a liquid control device 1, a pressurized liquid mixing device 4 and a negative pressure suction device 2. The liquid control device 1 is used to supply oil pipes and sleeves Input thin oil into the annular space between them and collect the return oil in the oil pipe. The pressurized liquid mixing device 4 is used to pressurize the thin oil in the annular space between the input oil pipe and the sleeve. The negative pressure suction device 2 Used to provide suction for return oil in the oil pipe. The liquid outlet of the liquid control device 1 is connected to one end of the oil mixing pipe 6, the other end of the oil mixing pipe 6 is connected to one end of the thin oil output pipe 3, and the other end of the thin oil output pipe 3 extends into the gap between the oil pipe and the sleeve. In the annular space, the pres...

Embodiment approach 2

[0066] Such as Figure 1 to Figure 4 As shown, the present invention provides a kind of oil well induced blowout technique, and this oil well induced blowout technique comprises the steps:

[0067] Step S1: Output the thin oil to the oil control mixing pipe 6 through the liquid outlet of the liquid control device 1, and transport the thin oil to the thin oil output pipe 3 through the oil mixing pipe 6; the oil mixing pipe 6 is provided with a wellhead furnace 10, and When the temperature of the thin oil in the oil pipe 6 is lower than the predetermined threshold, close the wellhead furnace connection valve 602 on the oil mixing pipe 6, open the wellhead furnace liquid inlet valve 1004 on the wellhead furnace liquid inlet pipe 1002 and the wellhead furnace outlet pipe 1003. The furnace outlet valve 1005 heats the thin oil in the oil mixing pipe 6 through the wellhead furnace 10 .

[0068] Step S2: Start the pressurized liquid mixing device 4 to pressurize the thin oil, press t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com