Motor train unit axle residual life estimation method based on ResNet and GRU

A technology for EMUs and axles, applied in special data processing applications, geometric CAD, computer-aided design, etc., can solve problems such as high maintenance costs and failure rates, and inability to accurately predict the insufficient maintenance of bogie axles, etc., to achieve in-depth improvement The effect of feature extraction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

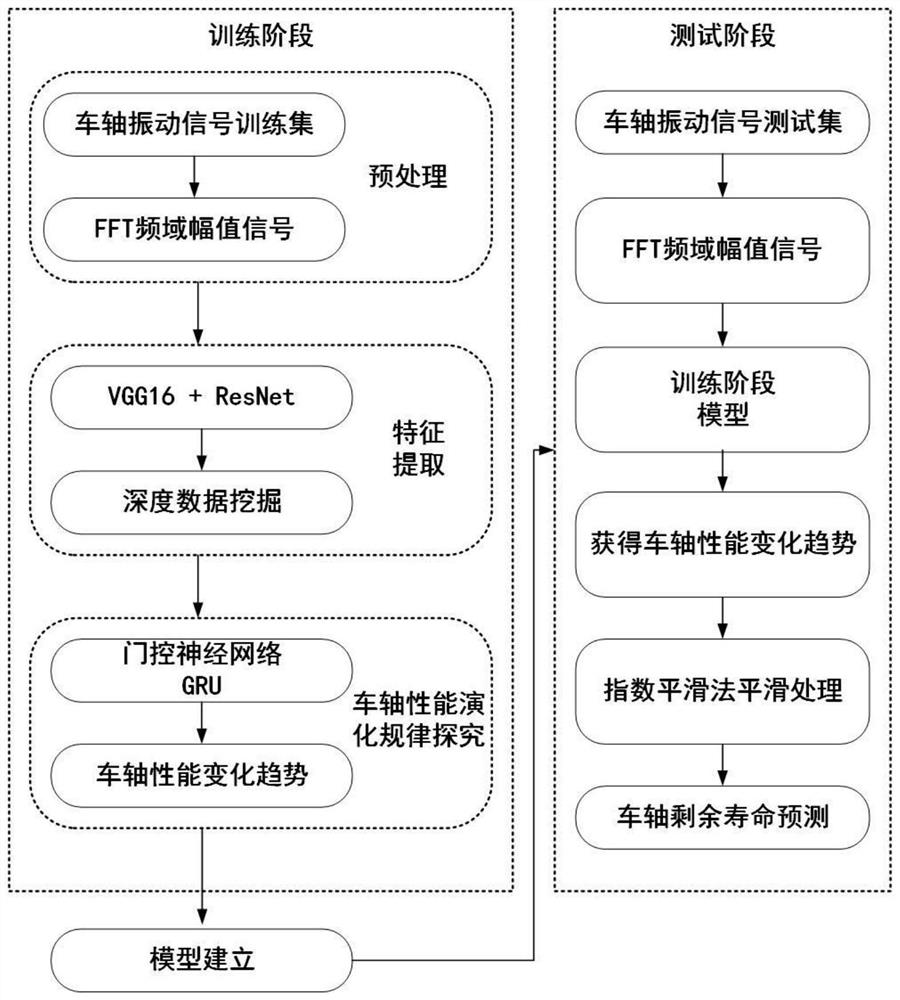

[0039] refer to figure 1 , a method for estimating the remaining life of an EMU axle based on ResNet and GRU is implemented as follows.

[0040] Perform FFT transformation on the bogie axle vibration signals collected under different working conditions, and obtain the amplitude signal data in the frequency domain as the training set;

[0041] The amplitude signal in the frequency domain is normalized by the BN algorithm and used as feature input, and the life degradation ratio of the axle is used as the output of the model for training. The formula is as follows:

[0042]

[0043] where x t ∈ R N Represents the N-dimensional feature input of the axle at time t; y t ∈[0,1] represents the life degradation rate of the axle at time t; V TRN Represents the vibration signal data of the axle under a certain working condition in the training set; R is the amplitude feature matrix in the frequency domain; T is the design life running time of the axle;

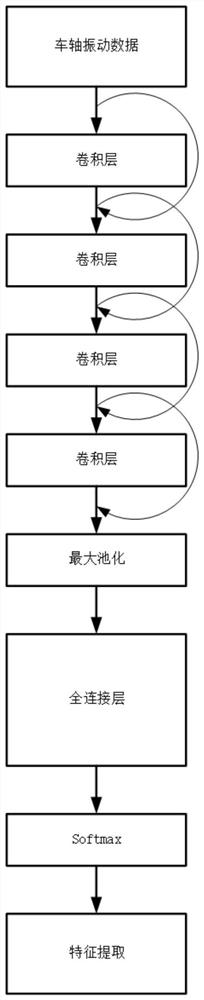

[0044] The VGG16 network...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com