Transformer magnetic core feeding device of power adapter

A technology for power adapters and transformers, which is applied in the manufacture of inductors/transformers/magnets, magnetic cores, and circuits. Force area, effect of clamping stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

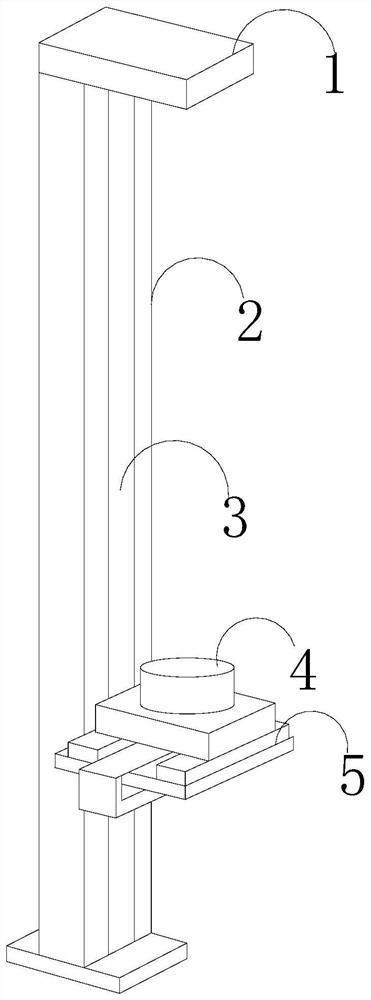

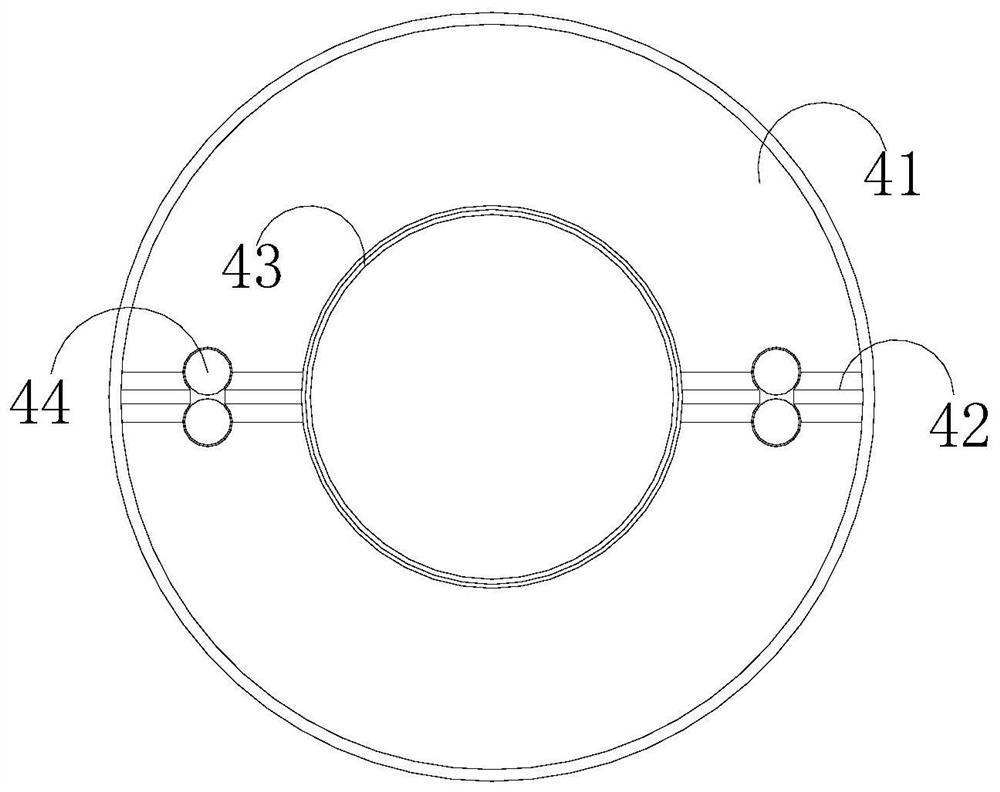

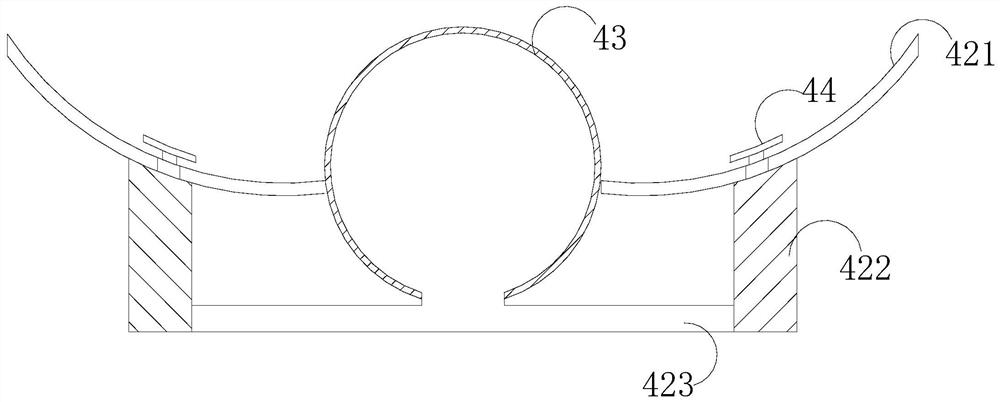

[0027] Such as Figure 1-Figure 6 As shown, the present invention provides a transformer magnetic core feeding device for a power adapter. The upper top plate 1 is fixed, the lifting screw 3 is installed on the supporting column 2, the lifting screw 3 is movably matched with the lifting base 5, and the lifting base 5 is provided with a clamping cavity 4, and the clamping cavity The inside of 4 is composed of a cavity 41, a sliding adjustment mechanism 42, an extruding air bag 43, and a clamping assembly 44. The cavity 41 is provided with a sliding adjustment mechanism 42 and an extruding air bag 43, and the extruding air bag 43 Cooperating with the clamping assembly 44, the sliding adjustment mechanism 42 is movably fitted with the clamping assembly 41. The sliding adjustment mechanism 42 includes an arc-shaped slide rail 421, a telescopic support shaft 422, and a connecting pipe 423. The arc-shaped The clamping assembly 44 is connected to the slide rail 421, and the telescop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com