Method and device for spraying surface of bonded neodymium-iron-boron magnet

A surface spraying and NdFeB technology, which is applied to the surface coating liquid device, liquid injection device, spraying device, etc., can solve the problem that the surface of bonded NdFeB magnet is easy to oxidize and rust, and the thickness of the coating is difficult to control. problems, to achieve the effect of improving product coating quality, avoiding oxidation and rust, and improving coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for spraying the surface of a bonded NdFeB magnet, comprising the following steps:

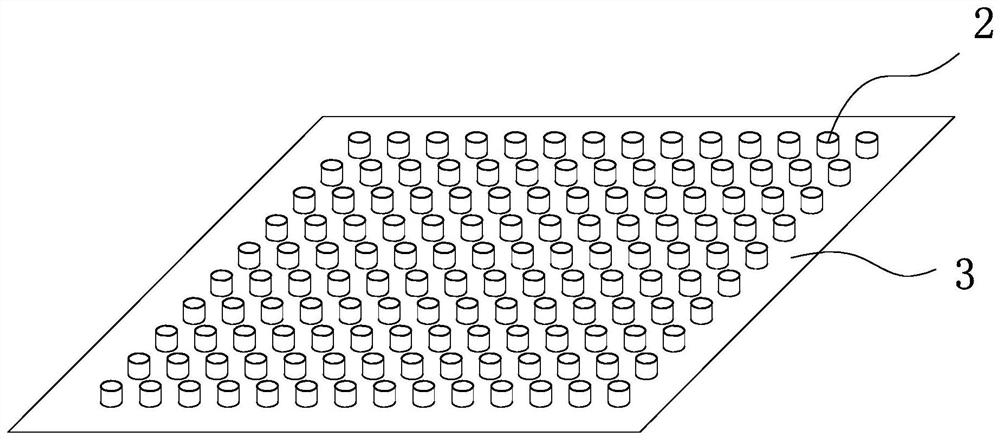

[0044] Step 1: Place several bonded NdFeB magnets on the plate 3 at equal intervals;

[0045] Step 2: Mix the epoxy resin paint and thinner according to the ratio of 1: (1.0-1.5) and stir evenly to form a spraying liquid;

[0046] Step 3: Press the mixed paint into the spray gun 1 through the booster pump 103, adjust the internal pressure of the spray gun 1 and the position of the spray gun 1 to form a uniform spray;

[0047] Step 4: Control the uniform movement of the spray gun 1, and control its moving track and working state, and spray the product 2 above the flat plate 3;

[0048] Step 5: The plate 3 is rotated several times, and step 4 is repeated after each rotation until the coating film thickness reaches the required thickness.

[0049]In the above technical scheme, the bonded NdFeB magnet is the product 2, and the product 2 is placed on the flat plate 3 at equal inte...

Embodiment 2

[0054] The technical solution of embodiment 2 is basically the same as the technical solution of embodiment 1, and its difference is: in step one, the distance between adjacent bonded NdFeB magnets is greater than the height of bonded NdFeB magnets, such The setting is beneficial to avoid mutual shielding between adjacent products 2 during the spraying process, thereby affecting the uniformity and dimensional accuracy of the coating.

Embodiment 3

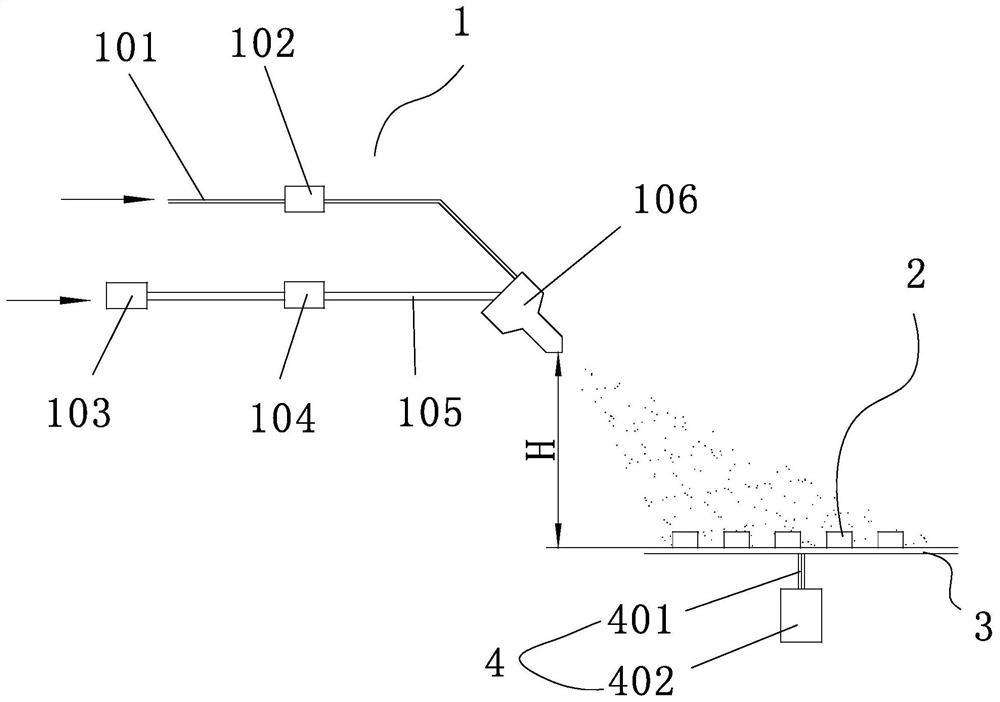

[0056] Such as figure 1 , figure 2 In the shown embodiment 3, a bonded NdFeB magnet surface spraying device includes a spray gun 1 and a flat plate 3, the spray gun 1 is used to spray the product 2, the flat plate 3 is used to place the product 2, and the spray gun 1 is arranged on the flat plate Above 3, there is a distance H between the spray gun 1 and the flat plate 3. In this technical solution, the spray gun 1 is used to spray the product 2, and the flat plate 3 is used to place the product 2, wherein the spray gun 1 and the flat plate 3 are provided with The distance H is convenient for the spray gun 1 to spray the product 2, avoiding the direct contact between the spray gun 1 and the product 2 during the moving process; at the same time, by adjusting the internal parameters of the spray gun 1, the spraying liquid can be sprayed evenly to ensure the uniform coating on the product 2.

[0057] In addition, the plate 3 is set as a metal material with magnetic adsorption, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com