A concrete mixing device

A mixing device and concrete technology, which is applied in the mixing operation control device, clay preparation device, mixing operation control and other directions, can solve the problems of inconvenient use, inability to mix materials, and insufficient mixing and mixing, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

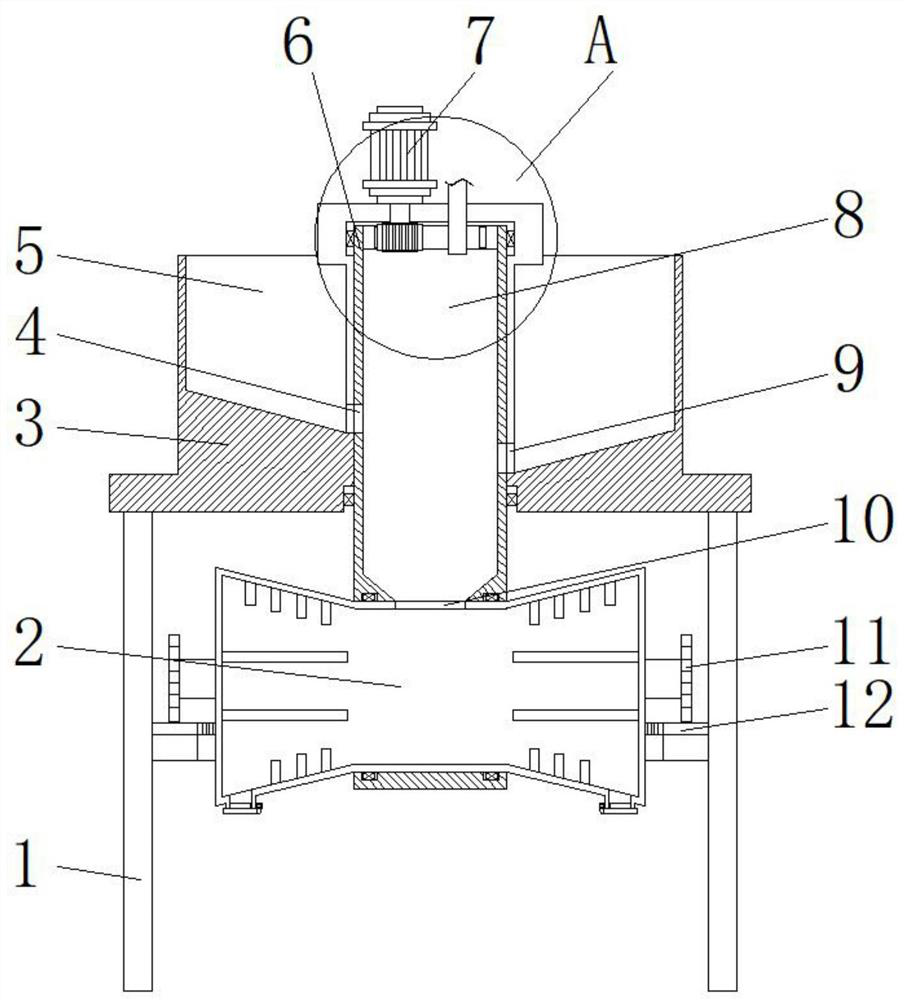

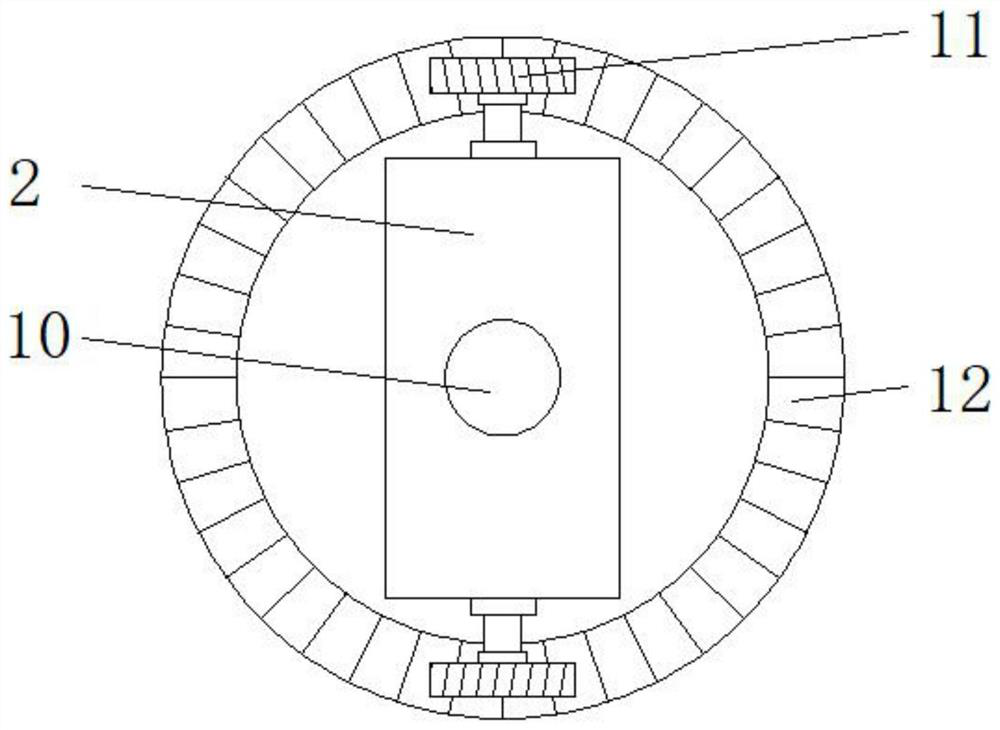

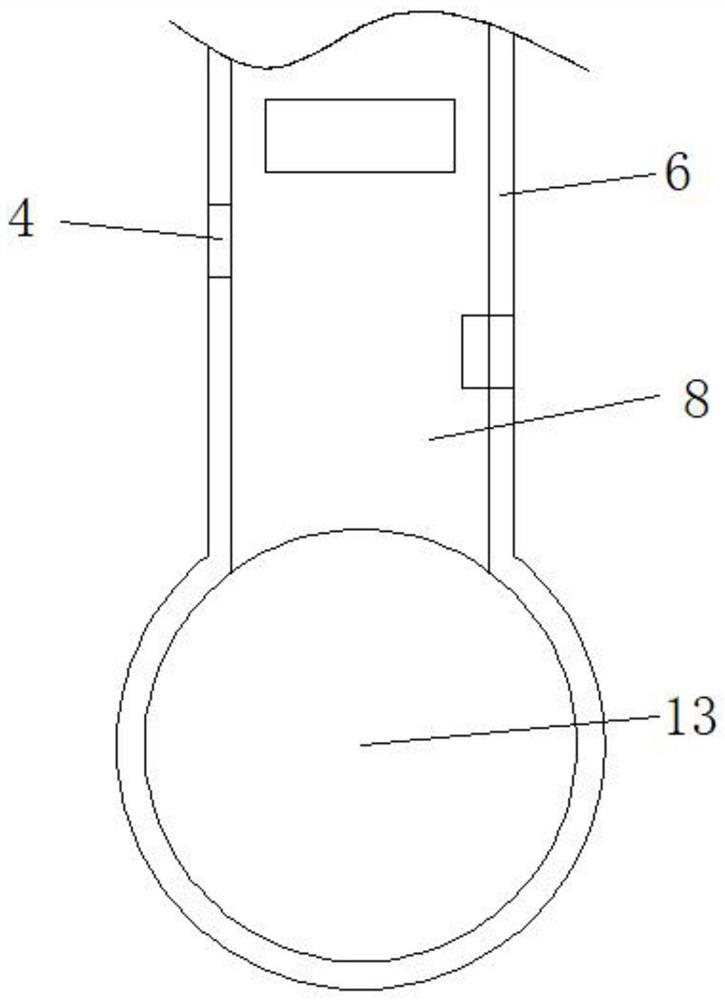

[0025] like Figure 1-6 The shown concrete mixing device includes a mixing cylinder 2, a fixing base 3 and a connecting cylinder 6. A second connecting cavity 14 is vertically opened at the center of the fixing base 3, and the fixing base on the outside of the second connecting cavity 14 is provided. 3. There are three storage cavities 5 equidistantly spaced with the second connecting cavity 14 as the center of the circle. The inner wall between the second connecting cavity 14 and the storage cavity 5 is provided with a first feeding port 9, and the second connecting cavity 14 The upper and lower ends of the interior are installed with a connecting cylinder 6 through bearings, and a material guide cavity 8 is opened at the middle position of the connecting cylinder 6. A second ring gear 19 is welded on the inner wall of the material guide cavity 8 at the top of the connecting cylinder 6, and the second ring gear 19 is welded. Teeth are evenly distributed on the inner wall of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap