A sixteen-wheel four-way shuttle with transverse electromagnetic linkage

A transverse electromagnetic and linkage technology, applied in the field of shuttle vehicles, can solve the problems of increasing manufacturing, procurement and maintenance costs, reducing the utilization of three-dimensional warehouse space, reducing the number of shelves and compartments, etc., to improve the efficiency of cargo access and structure. Novel design and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In the following, the present invention will be described in detail and specifically through specific examples, so as to better understand the present invention, but the following examples do not limit the scope of the present invention.

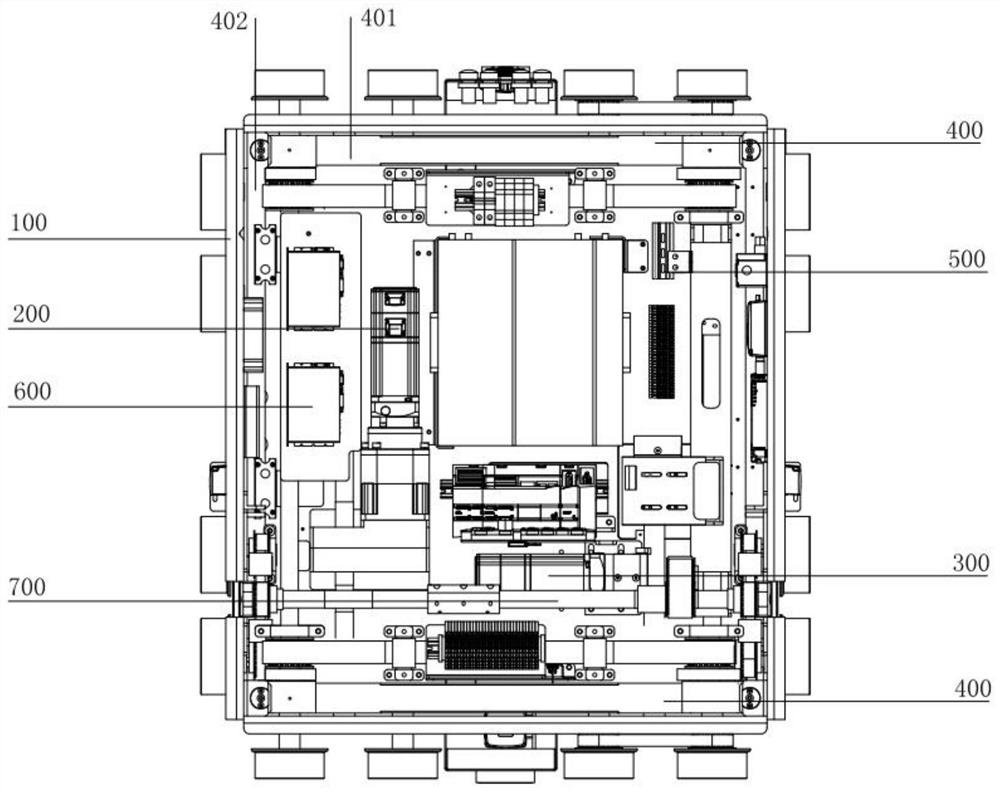

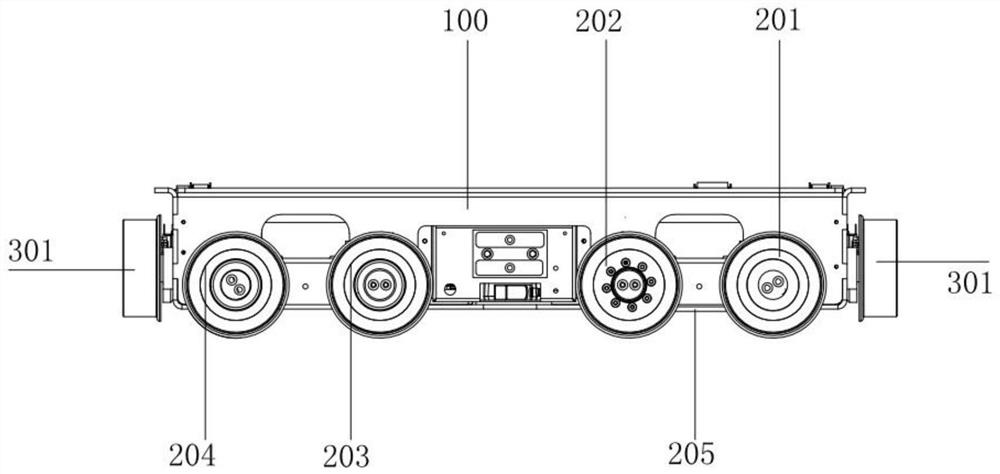

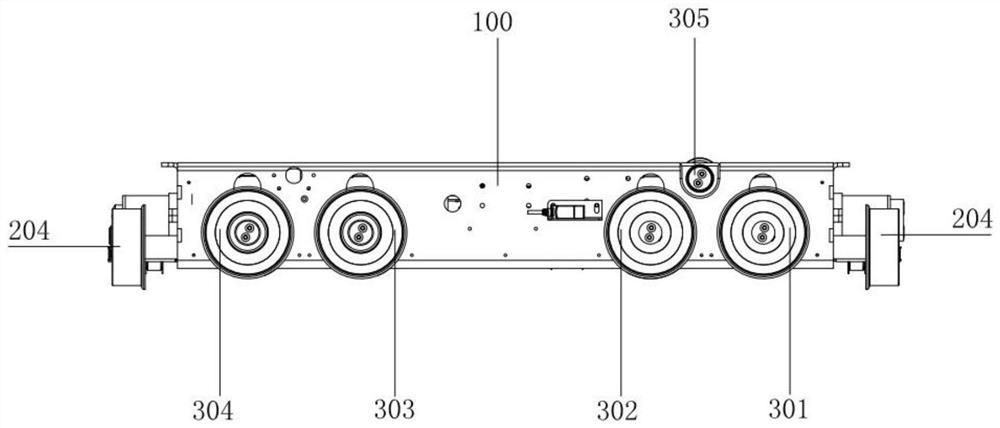

[0048] In some embodiments, such as figure 1 As shown, a sixteen-wheel four-way shuttle vehicle is provided, including a support frame 100, a lateral travel drive mechanism 200 installed on the support frame 100, a longitudinal travel drive mechanism 300, a clutch type jacking and reversing mechanism 400, and a battery pack 500 and controller 600.

[0049] In one of the embodiments, the support frame 100 is connected as a whole through sheet metal bending and local reinforcement, which greatly improves the carrying capacity of the vehicle; the battery pack 500 serves as a power source to increase the power of the vehicle, and the battery pack 500 can use lithium ion rechargeable battery, storage battery or any other energy storage ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com