Modular indoor floor for green fabricated building

A prefabricated and modular technology, applied in the direction of buildings, floors, building structures, etc., can solve the problems of not considering the corrosion resistance, affecting the safety of assembly floors, expansion, etc., so as to reduce the difficulty of management and ensure ecological protection Stability, effect of increasing diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

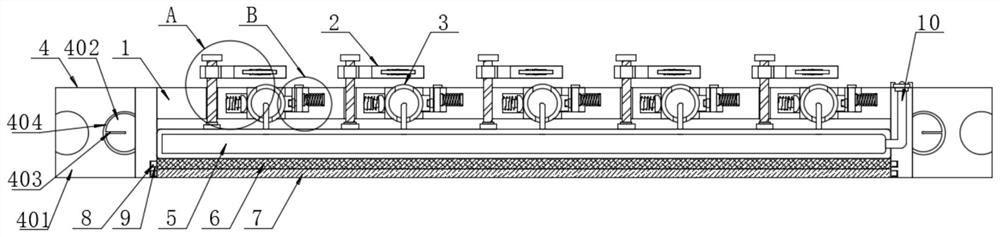

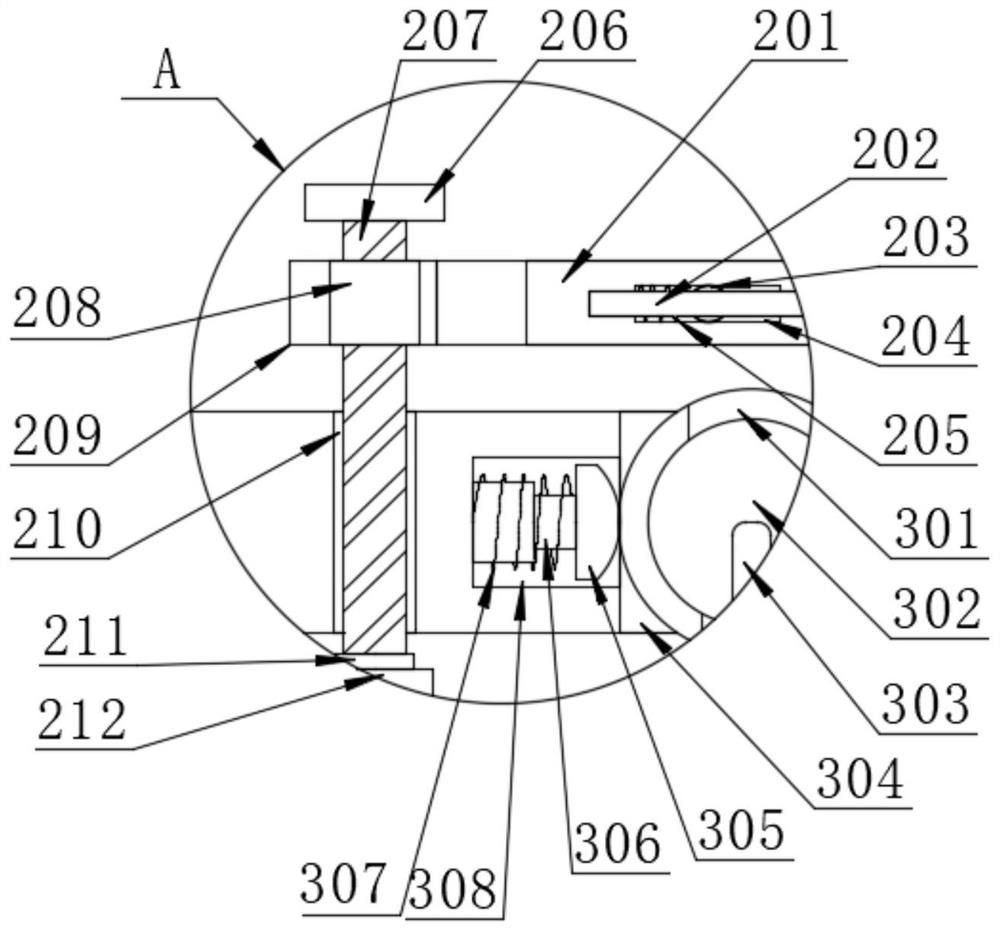

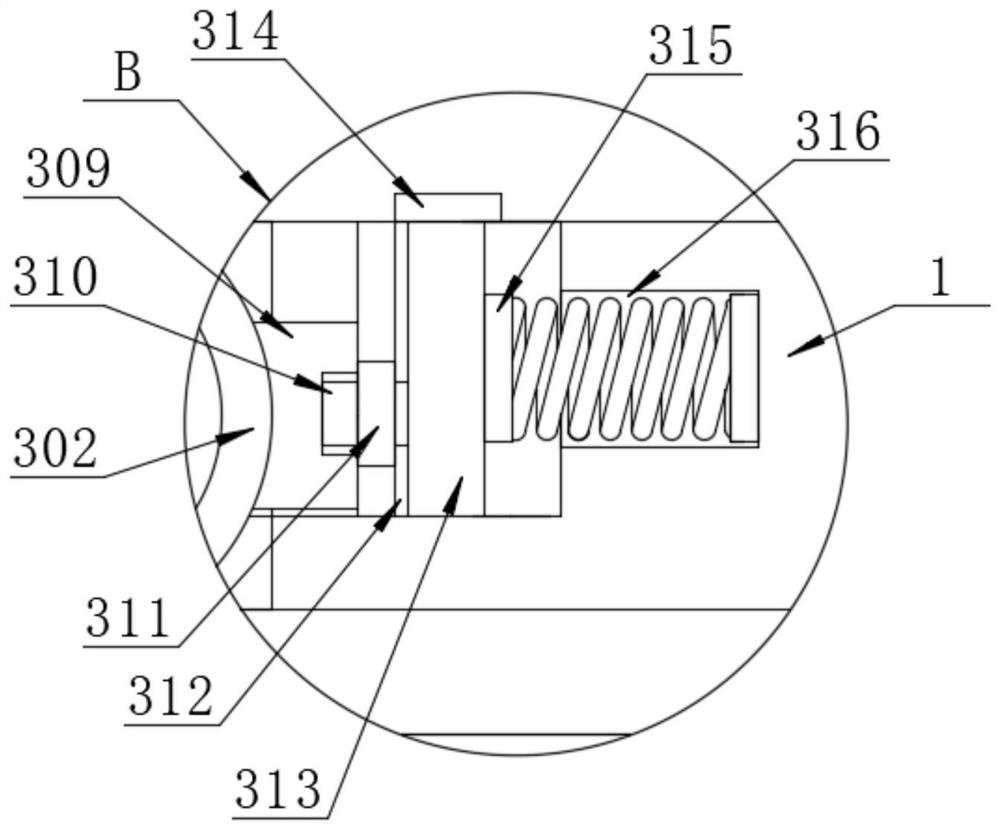

[0042] The embodiment is specifically: the floor body 1 can be inserted into the card slot 404 in the card seat 401 by pulling the card ball 402, so that the floor body 1 can be assembled and installed through the assembly of the card seat 401, and the floor body 1 can be conveniently installed. Assembled with the floor assembly frame, when the floor body 1 is assembled, the green plants can be put into the limiting rubber seat 302 through the emergence hole 301, and the limiting rubber seat 302 can be filled with a certain amount of cultivation soil To supply the nutrients needed for the production of green plants, and when the green plants and the limit rubber seat 302 are assembled, the limit rubber seat 302 can be snapped into the through groove 304 provided at the top of the floor body 1, and one side of the limit rubber seat 302 When the clamping block 309 and the second slide bar 310 are in the relative position, the first slide block 313 can be driven to slide in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com