Lead screw driving quadrilateral movement mechanism of automobile glass lifter

A motion mechanism, automotive glass technology, applied in the direction of power control mechanism, wing fan control mechanism, building structure, etc., can solve the problems of inability to realize automatic assembly line production, low production process safety factor, high manufacturing cost, etc. Achieve the effect of improving operational efficiency and stability, saving manufacturing human resources, and simplifying production and manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

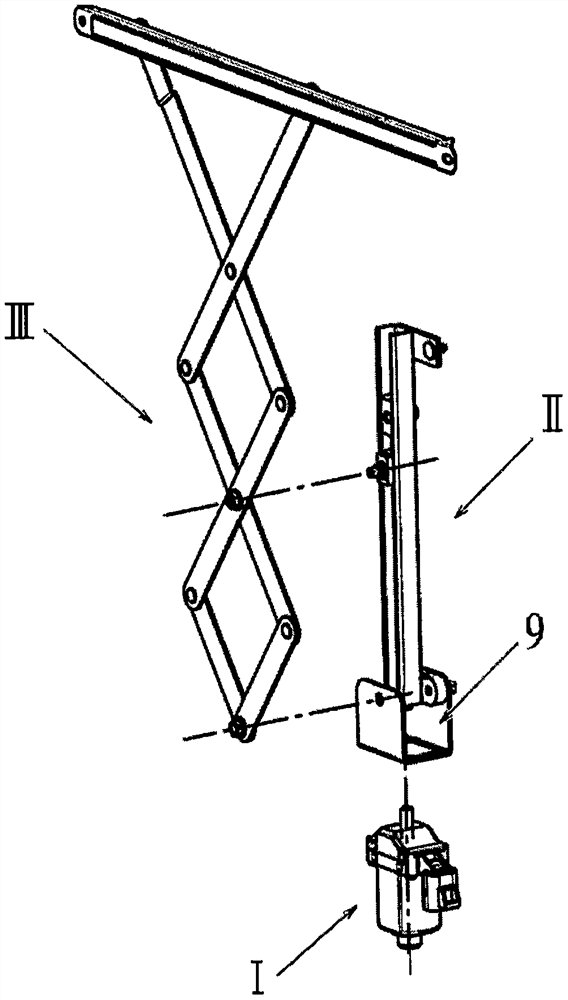

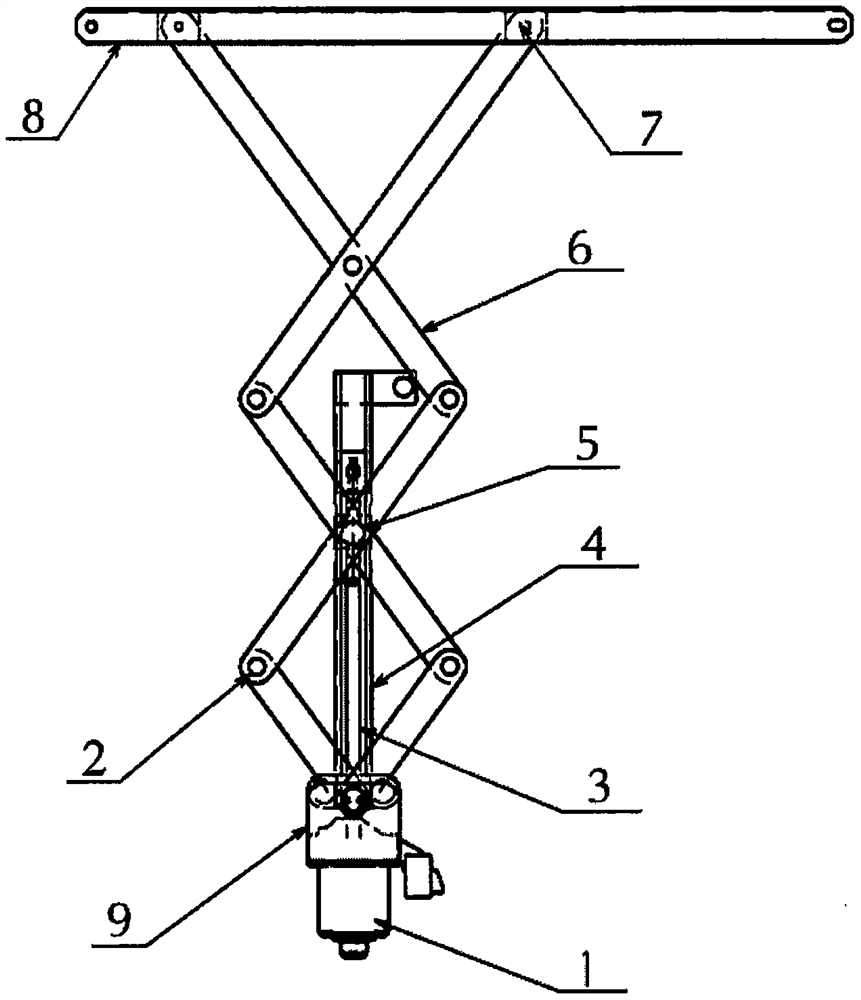

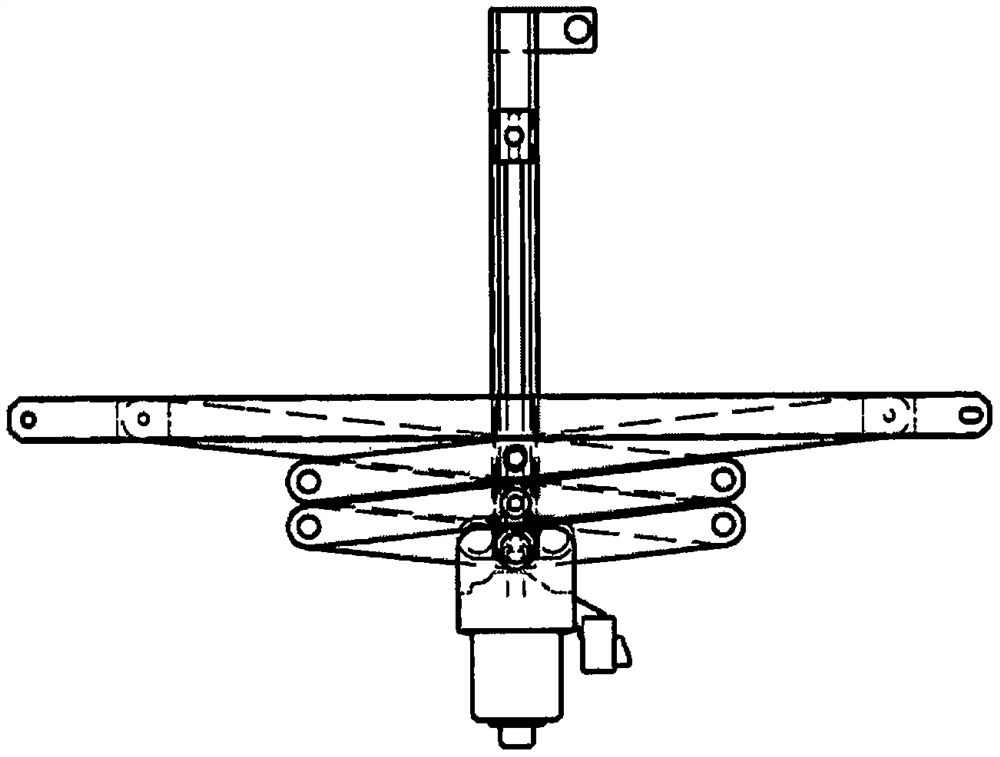

[0023] The quadrilateral movement mechanism driven by the screw rod of the automobile window regulator of the present invention breaks the traditional two structures and operation modes, and replaces the structure of the traditional automobile window regulator. Further description below in conjunction with accompanying drawings.

[0024] see figure 1 , The screw drive quadrilateral motion mechanism of a kind of automobile window lifter of the present invention is made up of drive mechanism I, transmission mechanism II and motion mechanism III three parts. see you again figure 2 with image 3 , the drive mechanism 1 is a motor 1. The transmission mechanism II includes a screw mandrel 3, a vertical guide rail 4 and a drive nut 5; the screw mandrel 3 is set in the vertical guide rail 4, and is limited to move up and down by the vertical guide rail 4, and the drive nut 5 is installed on the screw mandrel 3, and the The threads of rod 3 are engaged. The movement mechanism III...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com